css platform connecting bridge area segmental manufacturing process and special oblique tire frame

A technology of segmented manufacturing and connecting bridges, which is applied in ship construction, ship components, ships, etc., can solve the problem of increasing the difficulty of welding and the workload of welding seam repairs, is not conducive to the advancement of segmented manufacturing and group technology, and is difficult to guarantee the quality of the connection. and other problems to achieve the effect of shortening the segmented production cycle, optimizing the assembly procedure and welding position, and improving the production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] In order to describe the technical content, structural features, achieved goals and effects of the present invention in detail, the following will be described in detail in conjunction with the embodiments and accompanying drawings.

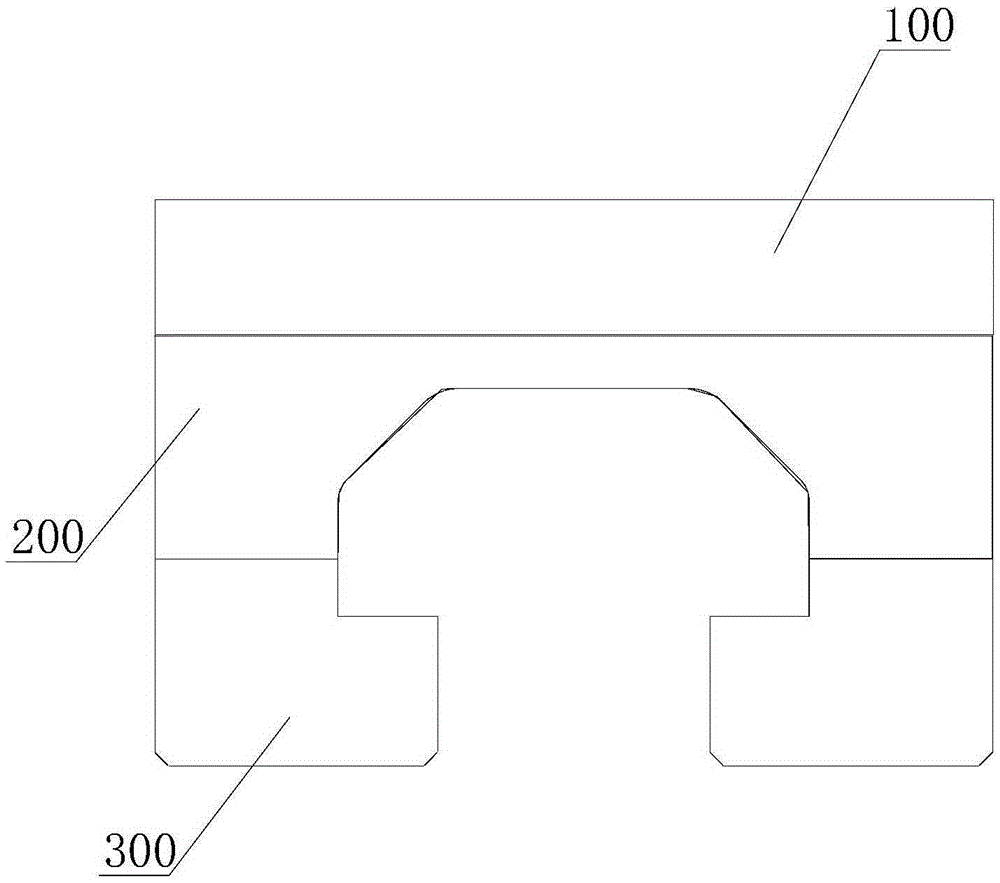

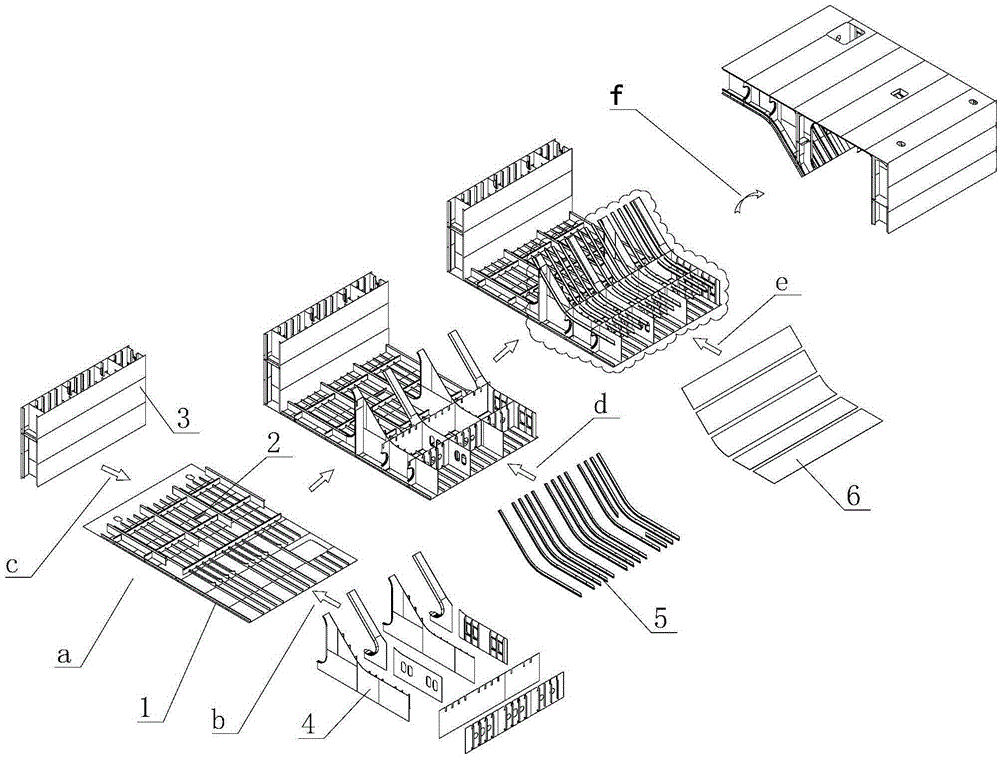

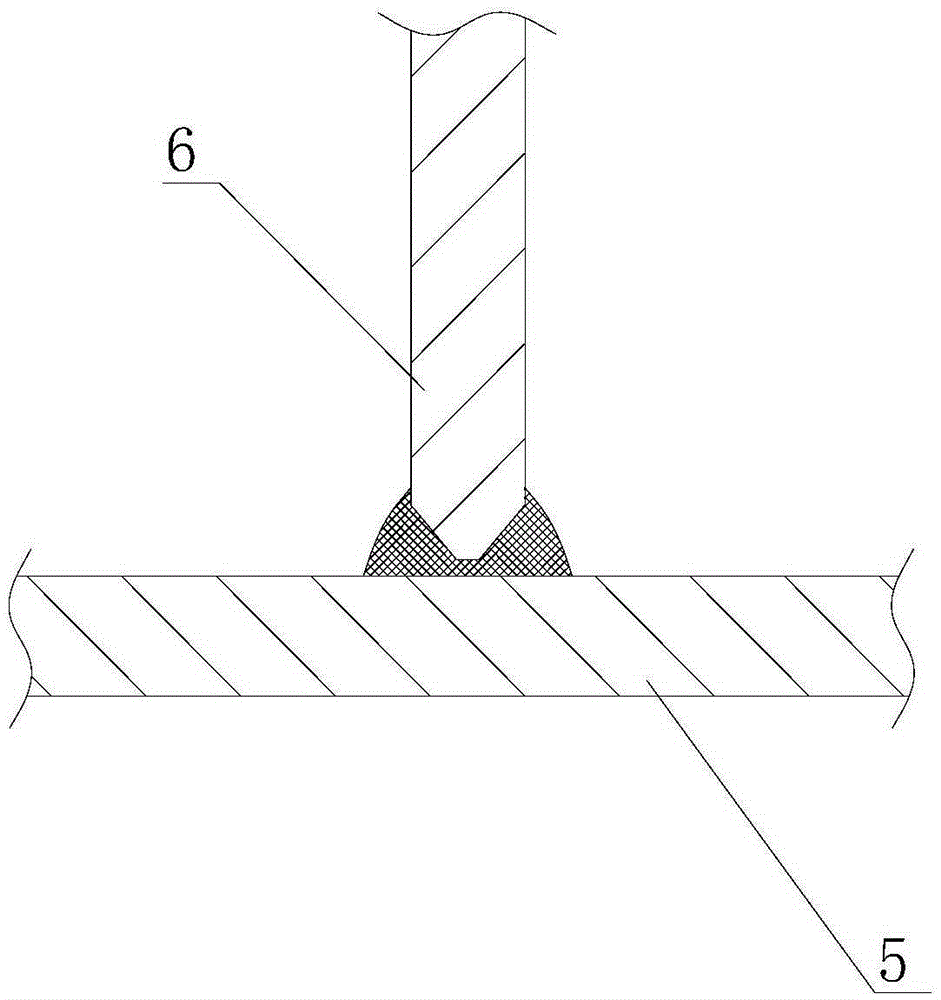

[0044] see Figure 4 , the present invention provides a segmental manufacturing process of CSS platform connecting bridge region 200, which includes Assembled in deck pieces , Assembled in inner and outer panels as well as large group three parts. Among them, the assembly of the inner outer plate is the most different step in this manufacturing process, which includes the steps: setting the inner outer plate beveled tire frame → hoisting the inner outer plate → welding → using the "ten" on the platform Mark the structure of the outer plate as a reference → hoist the structure on the outer plate and the vertical and horizontal wall plates → weld the fillet weld between the structure and the outer plate, weld the vertical weld between ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com