Preparation method of rare-earth element doped YxSm(l-x)BCO superconducting thin film

A yxsm1-xbco, superconducting thin film technology, applied in the field of doping modification of YBCO high temperature superconducting thin film materials, can solve problems such as the decrease of critical current density, and achieve the effect of improving field performance and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

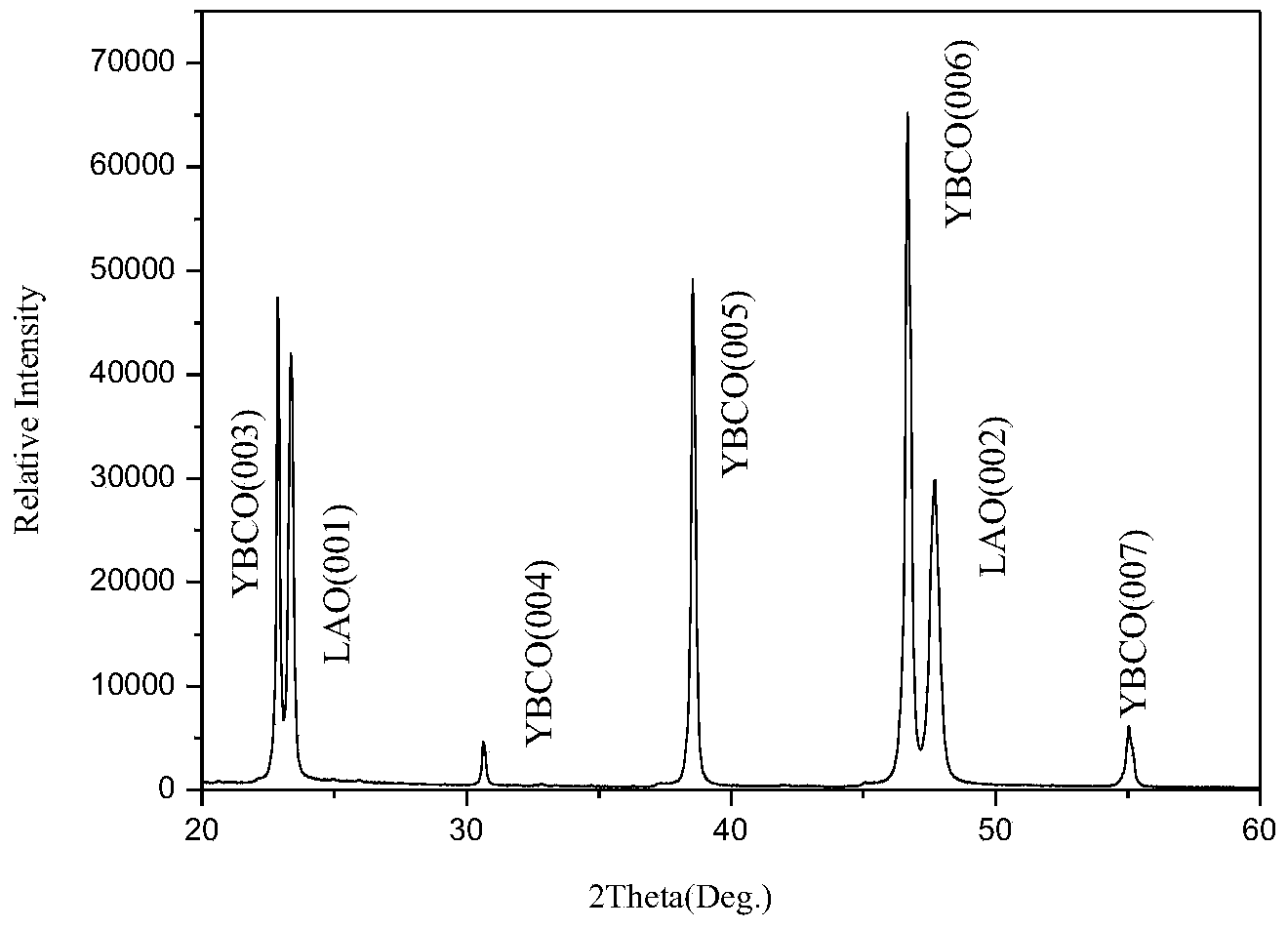

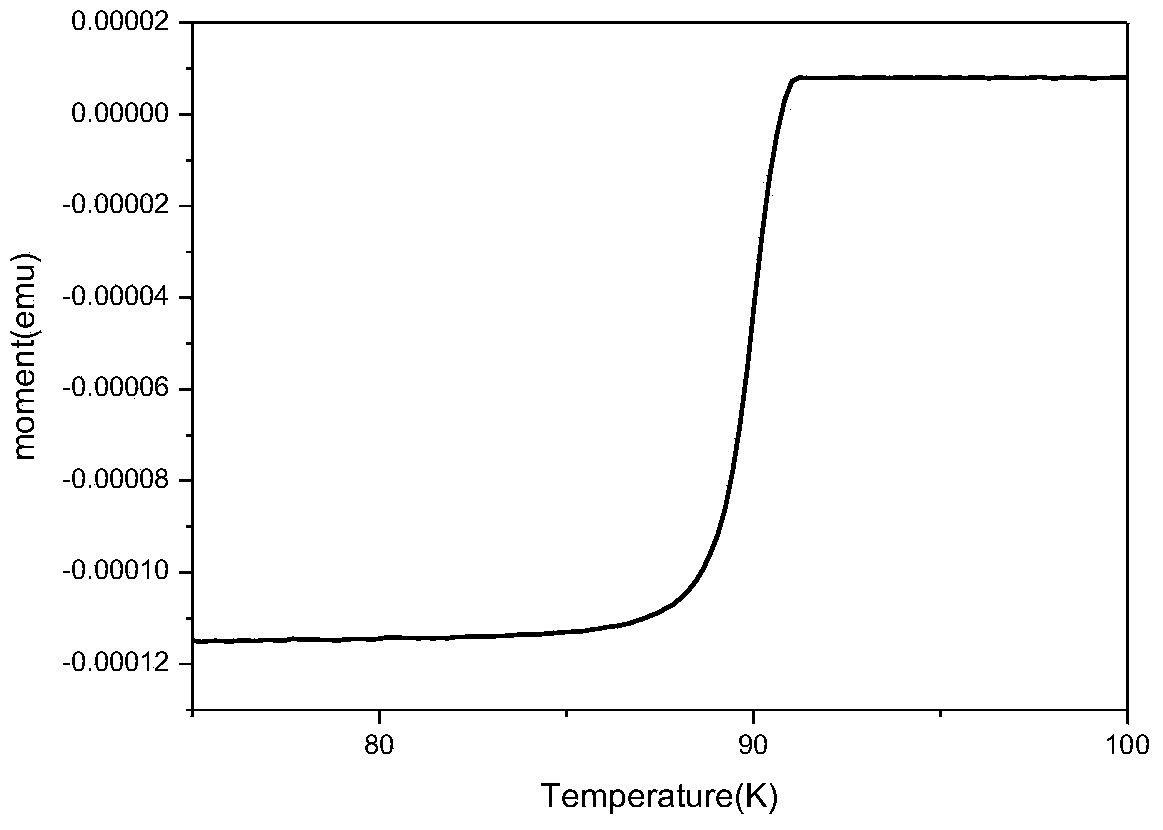

Image

Examples

Embodiment 1

[0029] Step S100: preparing palladium Pd nano dots:

[0030] Step S101: dissolving a certain amount of palladium acetylacetonate into n-propionic acid to obtain palladium ions Pd + A precursor solution with a concentration of 0.001mol / L;

[0031] Step S102: apply the precursor solution in step S101 on the single crystal of the lanthanum chlorate LAO substrate by spin coating, the coating time is 50s, and the rotation speed is 3000r / min;

[0032] Step S103: sintering the precursor film in step S102 at 1000° C. for 20 minutes under the protection of argon gas Ar, to generate palladium Pd nano-dots on the surface of the lanthanum chlorate LAO substrate, and obtain a lanthanum chlorate LAO substrate decorated with palladium Pd nano-dots;

[0033] Step S201: Dissolve yttrium acetate and barium acetate in deionized water at a molar ratio of 1:2, fully stir the mixture at 30-40°C, and wait for the mixture to dissolve into a mixed solution, then follow the steps of yttrium acetate an...

Embodiment 2

[0046] Step S100: preparing palladium (Pd) nanodots:

[0047] Step S101: dissolving a certain amount of palladium acetylacetonate into n-propionic acid to obtain a precursor solution with a palladium ion solubility of 0.002 mol / L;

[0048] Step S102: apply the precursor solution in step S101 on the LAO single crystal by spin coating, the coating time is 60 seconds, and the rotation speed is 3500 rpm;

[0049] Step S103: Sintering the precursor film in step S102 at 1200° C. for 60 minutes under argon protection to generate palladium (Pd) nano-dots on the surface of the substrate to obtain a substrate decorated with palladium (Pd) nano-dots;

[0050] Step S200: preparing Y through a low-fluorine process 0.75 SM 0.25 BCO precursor solution:

[0051] Step S201: Dissolving yttrium acetate and barium acetate in deionized water at a molar ratio of 1:2, stirring and dissolving at 40°C, then adding trifluoroacetic acid at a molar ratio of yttrium acetate to trifluoroacetic acid of 1...

Embodiment 3

[0061] Step S100: preparing palladium (Pd) nanodots:

[0062] Step S101: dissolving a certain amount of palladium acetylacetonate into n-propionic acid to obtain a precursor solution with a palladium ion solubility of 0.003 mol / L;

[0063] Step S102: Coating the precursor solution in step S101 on the LAO single crystal by spin coating, the coating time is 70 seconds, and the rotation speed is 4000 rpm;

[0064] Step S103: Sintering the precursor film in step S102 under the protection of high-purity argon at a temperature of 1300° C. for 120 minutes to generate palladium (Pd) nano-dots on the surface of the substrate to obtain a substrate decorated with palladium (Pd) nano-dots;

[0065] Step S200: preparing Y through a low-fluorine process 0.5 SM 0.5 BCO precursor solution:

[0066] Step S201: Dissolve yttrium acetate and barium acetate in deionized water at a molar ratio of 1:2, stir and dissolve at 40°C, then add trifluoroacetic acid at a molar ratio of yttrium acetate to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com