ZrO2 nanometer points of single material, and preparation method and application thereof

A technology of nano-dots and single crystal substrates, which is applied in nanotechnology, metal material coating technology, solid-state chemical plating, etc., to achieve the effect of single material and simple technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1) Dissolving zirconium acetylacetonate into n-propionic acid to prepare a 0.001mol / L precursor solution;

[0030] 2) Apply the precursor solution to the (100) SrTiO by spin coating 3 On the single crystal substrate, the rotation speed is 2500rpm, and the time is 120s to obtain the precursor film;

[0031] 3) in H 2 Under gas protection conditions, the precursor film was sintered at 1000 °C for 1000 minutes to obtain ZrO 2 nano dots.

[0032] 4) The YBCO film was prepared by the low-fluorine MOD process on the transition layer substrate coated with nanodots.

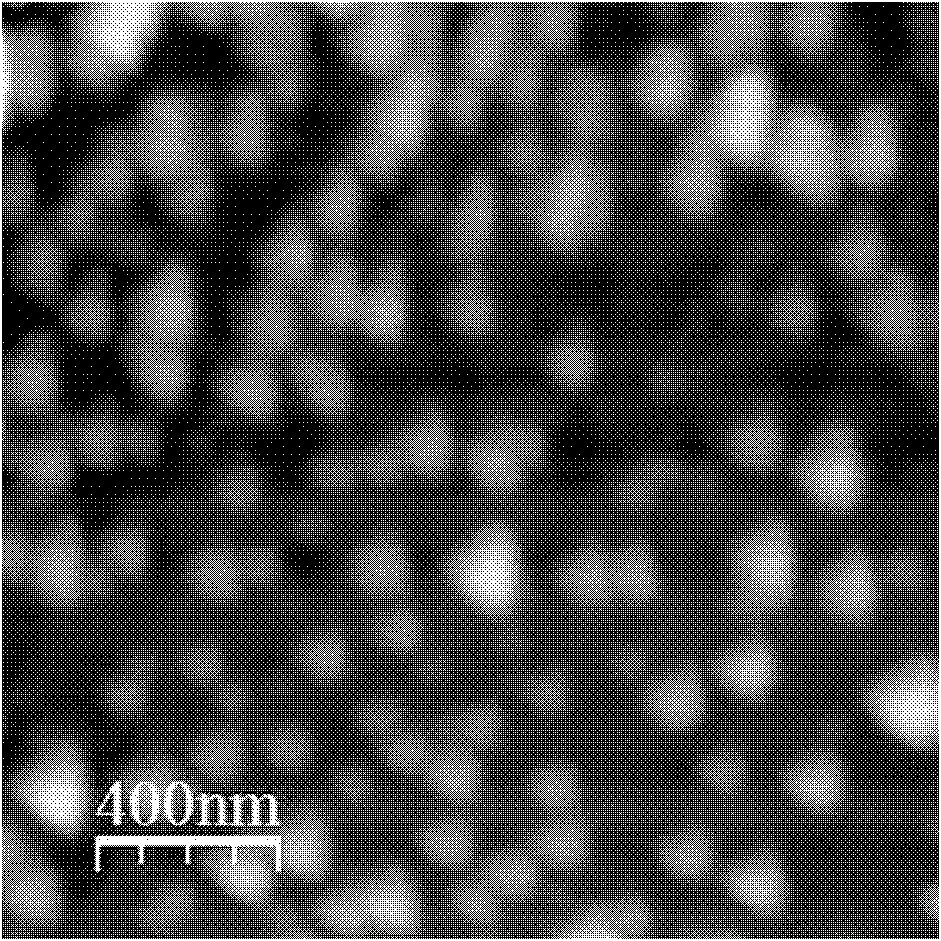

[0033] ZrO 2 The surface topography of figure 1 As shown, the AFM-2D photo shows that the nanodots are completely dispersed, with a density of 80 / μm, an average height of 5 nanometers, and an average diameter of 100 nanometers.

Embodiment 2

[0035] 1) Dissolving zirconium acetylacetonate into n-propionic acid to prepare a 0.03mol / L precursor solution;

[0036] 2) Apply the precursor solution to the SrTiO at 20 degrees to the (100) direction by spin coating 3 On the single crystal substrate, the rotation speed is 5000rpm, and the time is 40s to obtain the precursor film;

[0037] 3) in H 2 Under gas protection conditions, the precursor film was sintered at 1300 °C for 100 minutes to obtain ZrO 2 nano dots.

[0038] 4) The YBCO film was prepared by the low-fluorine MOD process on the transition layer substrate coated with nanodots.

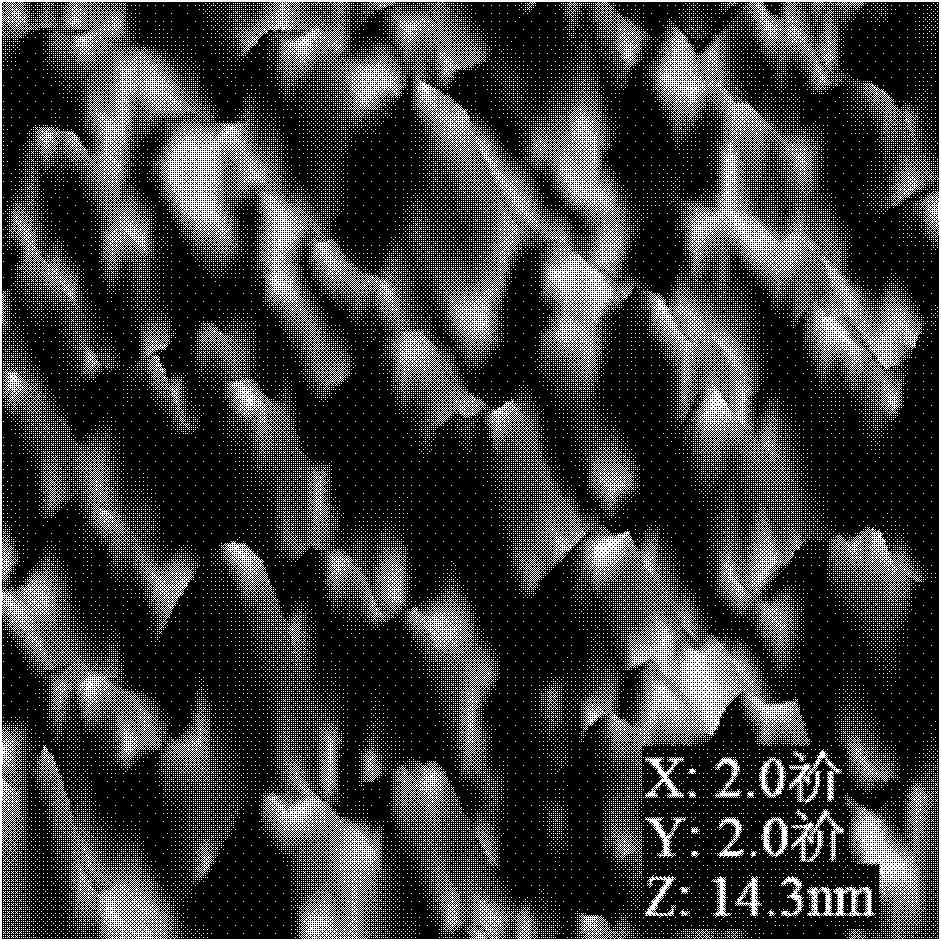

[0039] ZrO 2 The three-dimensional surface morphology of figure 2 As shown, the morphology of the nanodots in this AFM-3D photo is regular. The density is 10 / μm; the height is 14nm; the diameter is 200nm.

Embodiment 3

[0041] 1) Dissolving zirconium acetylacetonate into n-propionic acid to prepare a 0.005mol / L precursor solution;

[0042] 2) Apply the precursor solution to the LaAlO with a deviation of 10 degrees from the (100) direction by spin coating 3 On the single crystal substrate, the rotation speed is 4000rpm, and the time is 60s to obtain the precursor film;

[0043] 3) in H 2 Mixing with Ar (H 2 The volume percentages of Ar and Ar are 4% and 96%, respectively) under gas protection conditions, the precursor film was sintered at 1150 ° C for 300 minutes to obtain ZrO 2 nano dots.

[0044] 4) The YBCO film was prepared by the low-fluorine MOD process on the transition layer substrate coated with nanodots.

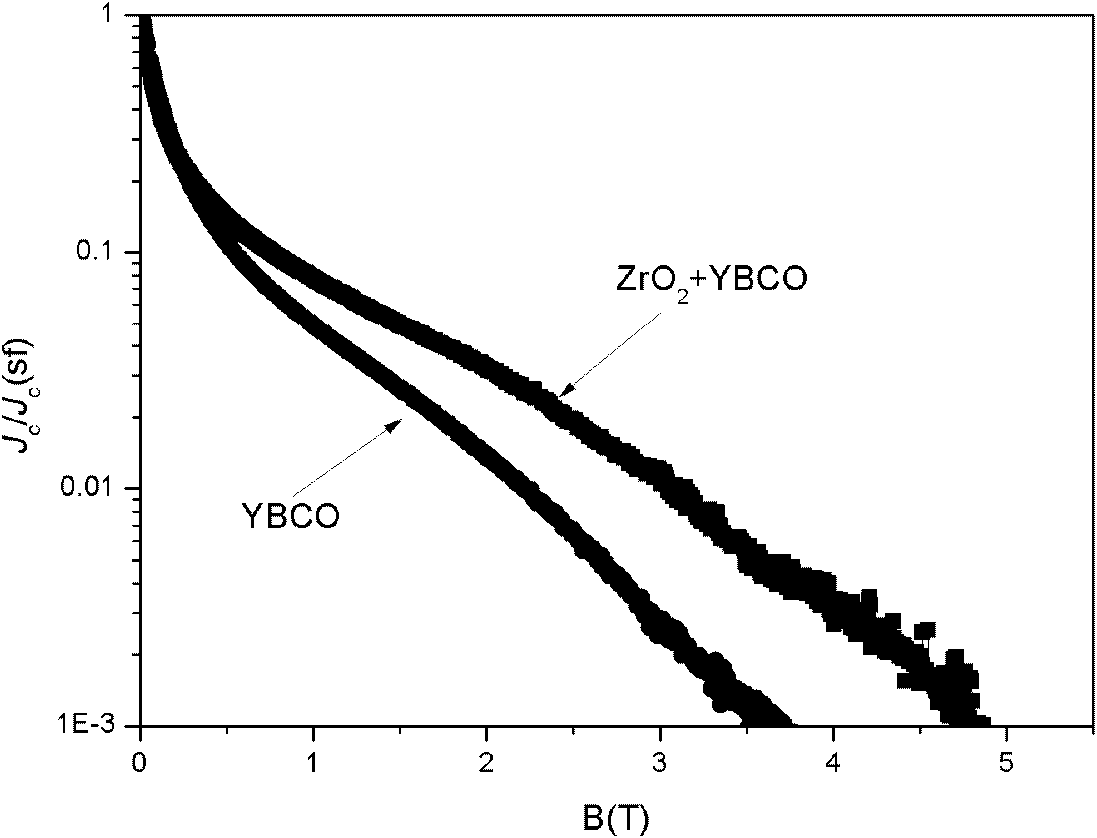

[0045] image 3 ZrO 2 J after normalization of +YBCO and blank YBCO e picture; Figure 4 ZrO 2 +YBCO normalized J e value (J e / J e (sf)) and the logarithm of the external magnetic field (77K), that is, the α curve. image 3 the J e The curve shows that ZrO 2 +YBCOJ ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com