Microbial organic fertilizer and preparation method thereof

A microbial organic fertilizer and mixture technology, which is applied in fertilization equipment, fertilizer mixture, application, etc., can solve the problems of low microbial content, low active ingredients, and unreasonable formula of organic fertilizers, and achieve long-lasting high temperature composting, high active ingredients, warm up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] A microbial organic fertilizer, which is produced by mixing and fermenting the following raw materials in mass percentages: cow dung with a water content of 50wt%-60wt%: 51.8%; soot residue: 15%; rice bran meal: 8%; straw powder: 8% %; bone residue: 5%; 80 mesh shell powder: 12%;

[0041] The preparation method of above-mentioned microbial organic fertilizer is:

[0042] (1) Mixing and stirring the cow dung, smoke residue, rice bran meal, straw powder, bone residue, shell powder and Bacillus licheniformis in the above parts by weight to obtain a mixture 1;

[0043] (2) Transport the mixture 1 into the space vacated at the front end of the fermentation tank every day, and the delivery volume is 1 / 8 of the length of the fermentation tank. The oxygen provided by the contact between the material and the air during the period of forced ventilation and turning is used for pool-type aerobic continuous fermentation, so that the fermented material can be rapidly decomposed, ste...

Embodiment 2

[0049] A microbial organic fertilizer, which is made by mixing and fermenting the following raw materials in mass percentage: pig manure with a water content of 50wt%-60wt%: 69.74%; soot residue: 5%; rice bran meal: 3%; grass powder: 2% ; Bone residue: 15%; 80 mesh shell powder: 5%; Bacillus licheniformis: 0.13%;

[0050] The preparation method of above-mentioned microbial organic fertilizer is:

[0051] (1) Mixing and stirring the pig manure, tobacco residue, rice bran meal, grass powder, bone residue, shell powder, and Bacillus licheniformis in the above parts by weight to obtain a mixture 1;

[0052] (2) The mixture 1 is transported into the space vacated at the front end of the fermentation tank every day, and the delivery volume is 1 / 8 of the length of the fermentation tank. The thickness of the mixture 1 in the fermentation tank is 1.7m, and it is separated by a high-pressure fan. The oxygen provided by the contact between the material and the air during the period of f...

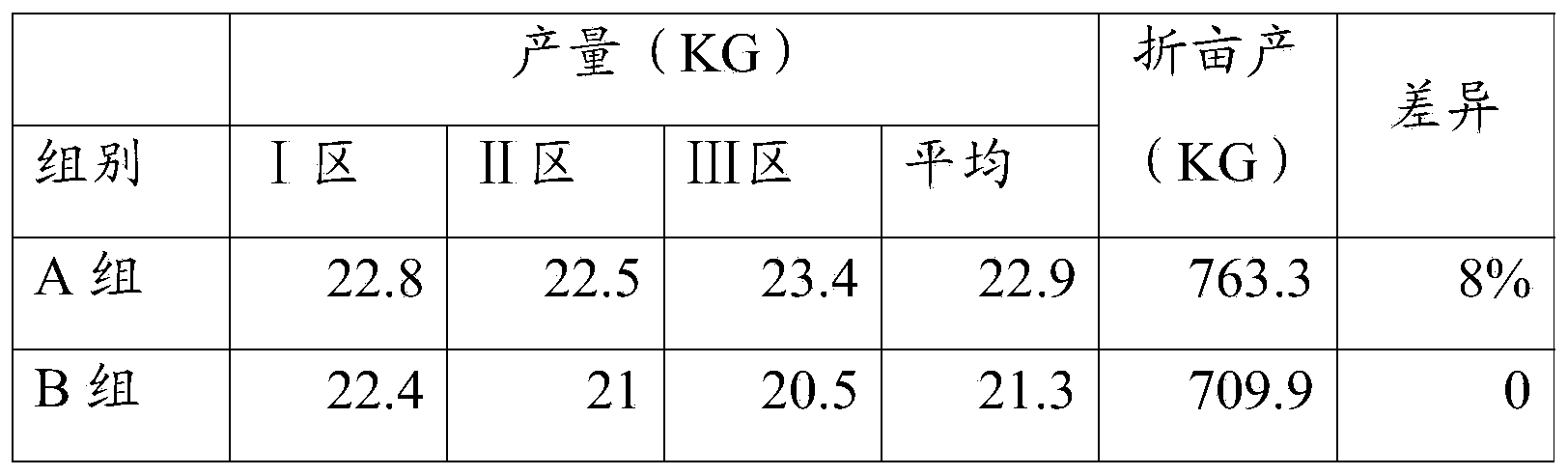

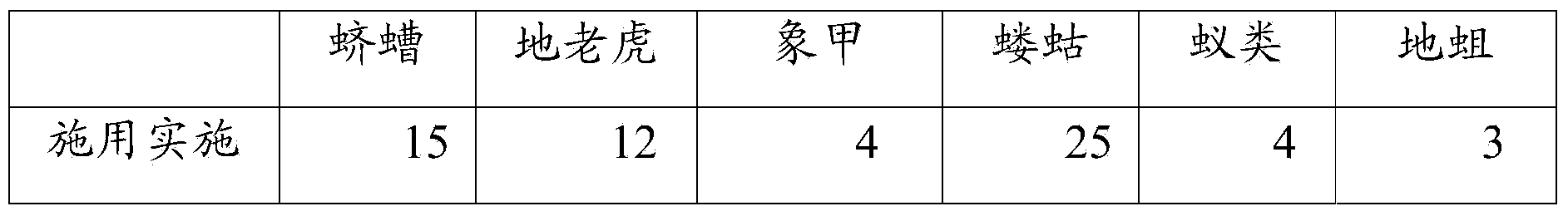

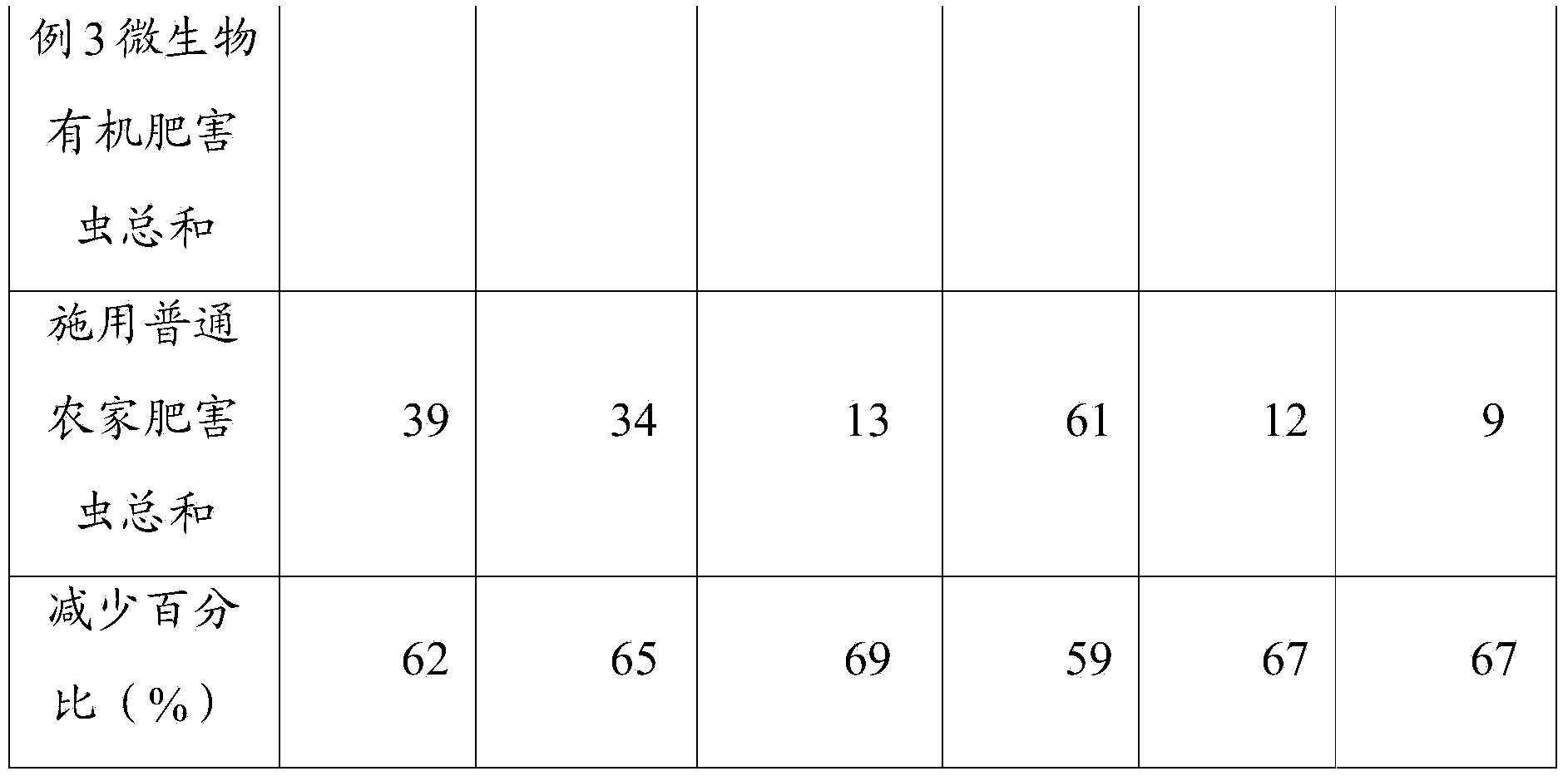

Embodiment 3

[0058] A microbial organic fertilizer, which is produced by mixing and fermenting the following raw materials in mass percentages: cow dung with a water content of 50wt%-60wt%: 61.76%; soot residue: 10%; rice bran meal: 5%; straw powder: 5% %; bone residue: 10%; shell powder: 8%; Bacillus licheniformis: 0.12%; Bacillus subtilis: 0.12%.

[0059] The preparation method of above-mentioned microbial organic fertilizer is:

[0060] (1) Mixing and stirring the cow dung, smoke residue, rice bran meal, straw powder, bone residue, shell powder and Bacillus licheniformis in the above parts by weight to obtain a mixture 1;

[0061] (2) The mixture 1 is transported into the space vacated at the front end of the fermentation tank every day, and the delivery volume is 1 / 8 of the length of the fermentation tank. The thickness of the mixture 1 in the fermentation tank is 1.6m, and it is separated by a high pressure fan The oxygen provided by the contact between the material and the air durin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com