Polypropylene composition and preparation method thereof

A polypropylene composition and technology of the composition, applied in the field of polypropylene composition and its preparation, can solve the problems of increasing impact resistance and spreading characteristics, and achieve the effect of excellent heat resistance and pressure resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

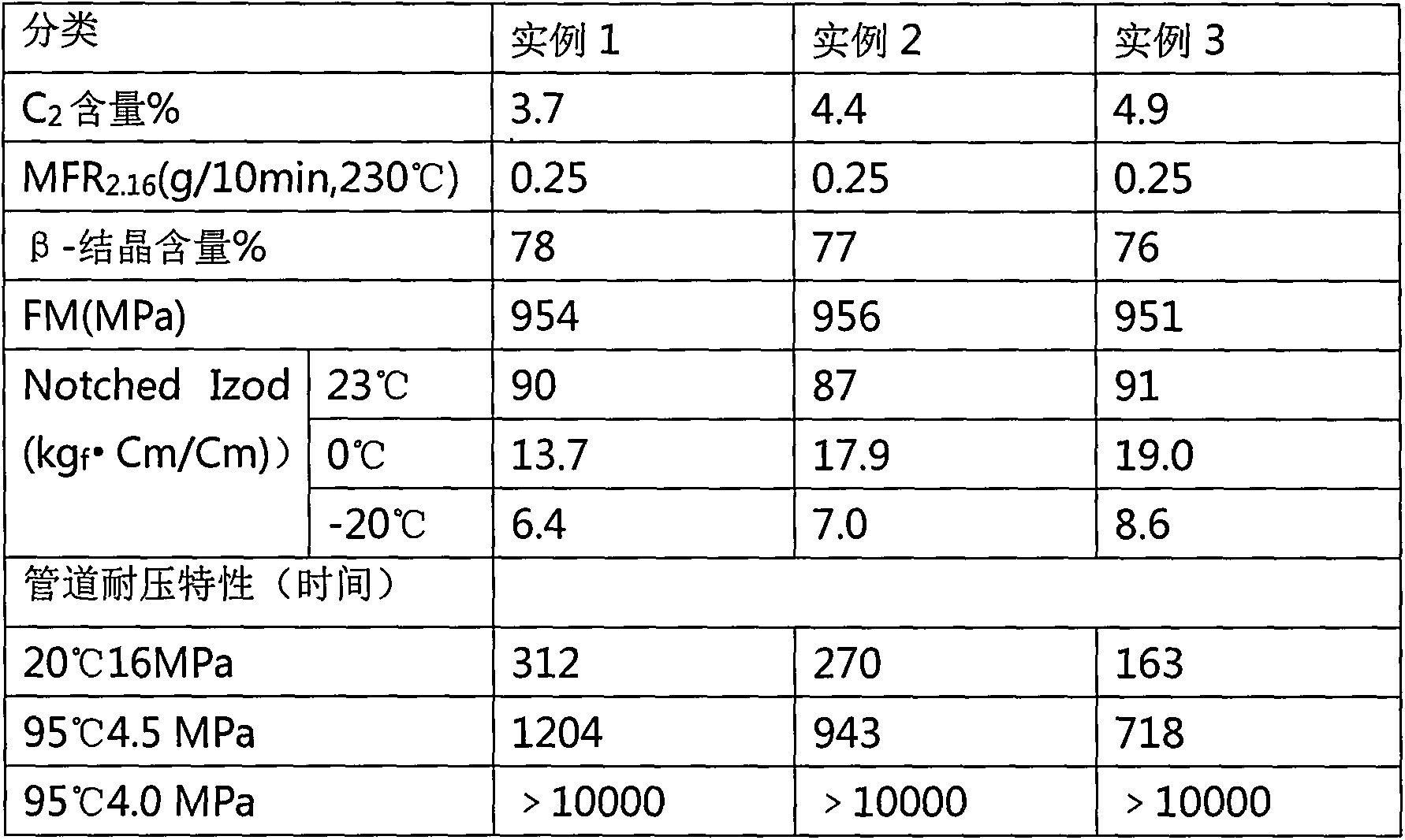

Examples

Embodiment 1

[0046] (Production of ethylene-propylene random-elastic copolymer composition (C-1))

[0047] Temperature is 60 ℃, under the condition of pressure 7kg / cm2, in the reactor that is full of hydrocarbon solvent, inject propylene and ethylene monomer simultaneously, carry out polymerization reaction until the content ratio of ethylene and propylene is 2.8%: 97.2%, making melt index is 0.1g / 10min ethylene-propylene random copolymer.

[0048] Remove unreacted or low molecular weight by-products in the above. Then adjust the temperature in the reaction device to 52°C and the pressure to 3kgf / cm 2 The strip is injected with ethylene and propylene, and polymerized until the content ratio of ethylene and propylene reaches 50%:50% to produce ethylene-propylene elastic polymer. At this time, the relative weight ratio of the ethylene-propylene random copolymer and the ethylene-propylene elastic polymer was 98:2.

[0049] The reaction product was statically placed in a water tank at a tem...

example 2

[0053] (Production of ethylene-propylene random-elastic copolymer composition (C-2))

[0054] Temperature 60 ℃, under the condition of pressure 7kg / Cm , in the reactor that contains nucleophilic solvent, inject ethylene and propylene simultaneously, carry out polymerization reaction until the content ratio of ethylene and propylene is 2.5% by weight: 97.5% by weight, and melt index is made 0.4g / 10min ethylene-propylene random copolymer.

[0055] Remove unreacted or low molecular weight by-products in the above. Then adjust the temperature in the reaction device to 52°C and the pressure to 3kgf / cm 2 The strip is injected with ethylene and propylene, and polymerized until the content ratio of ethylene and propylene reaches 50%:50% to produce ethylene-propylene elastic polymer. At this time, the relative weight ratio of the ethylene-propylene random copolymer and the ethylene-propylene elastic polymer was 98:2.

[0056] The reaction product was statically placed in a water tan...

example 3

[0060] Production of Ethylene-Propylene Random Elastic Copolymer Composition (C-3))

[0061] Temperature 60 ℃, under the condition of pressure 7kg / cm2, inject ethylene and propylene simultaneously in the reactor that contains nucleophilic solvent, carry out usual polymerization reaction until the content ratio of ethylene and propylene is 2% by weight: 98% by weight, produced An ethylene-propylene random copolymer (A) having a melt index of 0.4 g / 10 min.

[0062] Remove the micro-reaction gas formed by the above-mentioned unreacted, the temperature in the reaction device is 52 ℃, and inject ethylene and propylene under the condition of pressure 3kgf / cm2, add polymerization reaction until the content ratio of ethylene and propylene reaches 50% by weight: 50% by weight An ethylene-propylene elastomeric polymer (B) is produced. At this time, the above-mentioned ethylene-propylene elastic polymer (B) production reaction adjusted the polymerization time so that the relative weight...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

| Melt index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com