Anti-fading stamp-pad ink and preparation method thereof

A technology of anti-fading and printing ink, applied in the field of printing ink, can solve the problems of inability to achieve permanent preservation and use, not bright enough color, poor weather resistance, etc., and achieve good waterproof, good weather resistance and wide application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

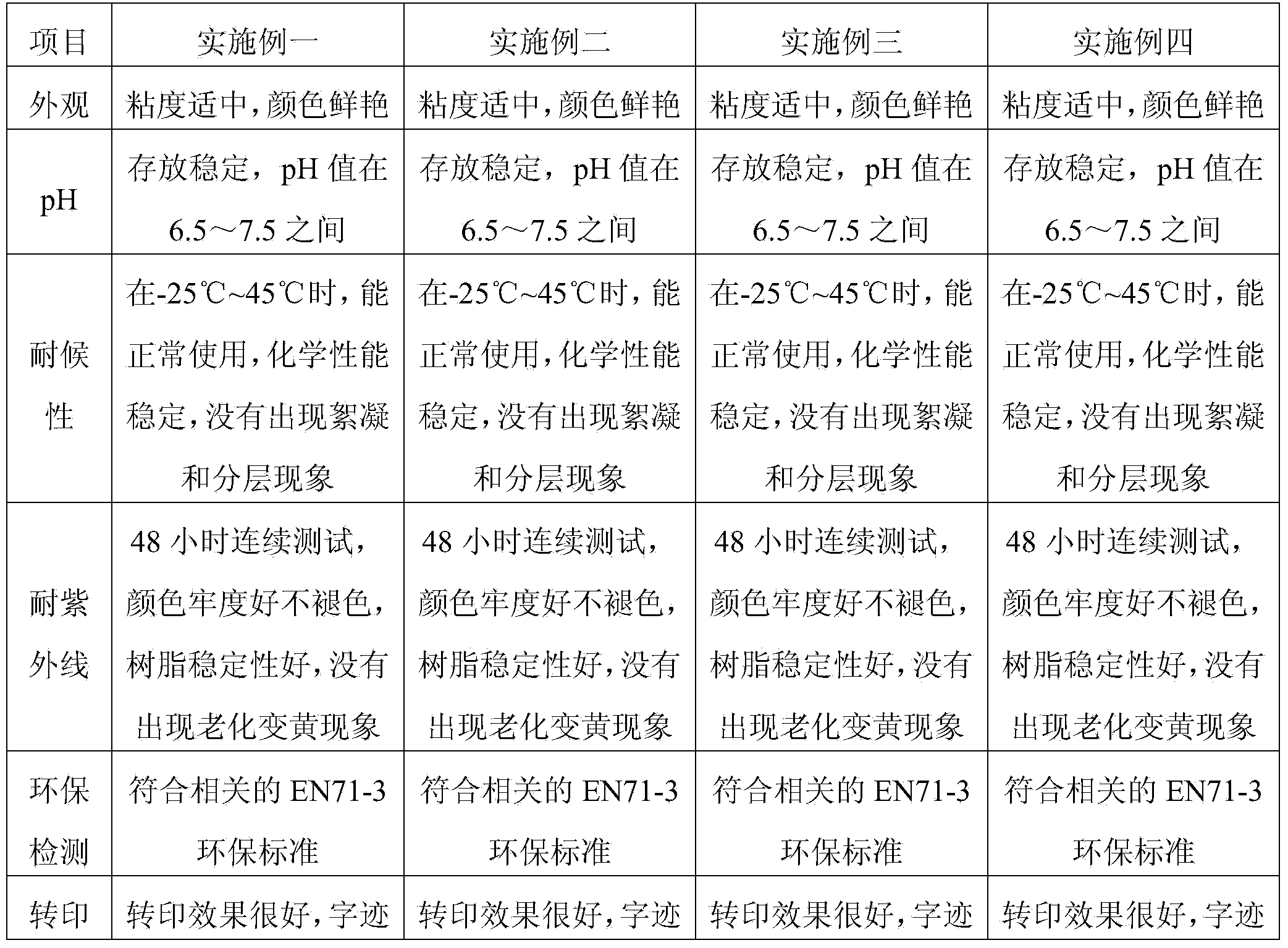

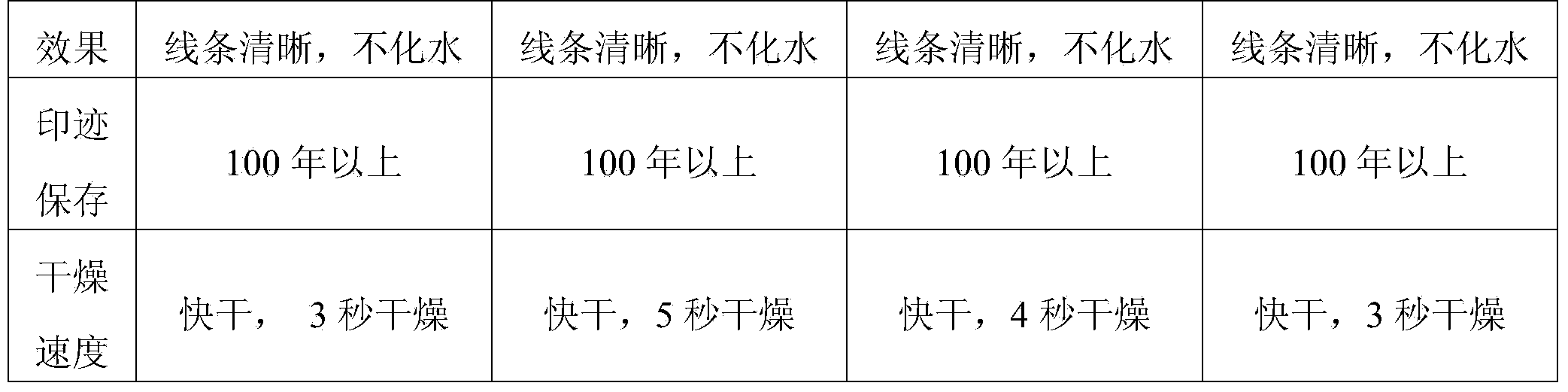

Examples

Embodiment 1

[0030] Mix 55kg of oily solvent, take 27.5kg of mixed oily solvent and heat it to 140℃, then slowly add 25kg of soluble resin, continue stirring at 500 rpm for dispersion, keep the temperature at 140℃, react for 180 minutes , Cooling to 90°C, adjusting the pH to 7.0, and then stirring at 850 rpm, stirring for 30 minutes, cooling, and filtering to obtain the mixed resin solution;

[0031] Take 10% of the mixed resin solution by weight, dilute it with the remaining 27.5kg of oily solvent after mixing, add 18kg of colorant to disperse, mix well, grind for 1.5 hours, and then add the remaining mixed resin Resin liquid, 1.8kg organic silicon and 0.2kg BHT, disperse at high speed for 2.5 hours, stand for 24 hours, and filter to obtain the finished product.

[0032] Among them, the oily solvent is composed of the following components in parts by weight: 45 parts castor oil, 15 parts stearate, 15 parts butanediol, 10 parts dimethyl maple, 14 parts mineral oil and 1 part triethanolamine. T...

Embodiment 2

[0034] Mix 55kg of oily solvent, take 27.5kg of mixed oily solvent and heat it to 140℃, then slowly add 25kg of soluble resin, continue stirring at 500 rpm for dispersion, keep the temperature at 140℃, react for 180 minutes , Cooling to 90°C, adjusting the pH to 7.0, and then stirring at 850 rpm, stirring for 30 minutes, cooling, and filtering to obtain the mixed resin solution;

[0035] Take 10% of the mixed resin solution by weight, dilute it with the remaining 27.5kg of oily solvent after mixing, add 18kg of colorant to disperse, mix well, grind for 1.5 hours, and then add the remaining mixed resin Resin liquid, 1.8kg organic silicon and 0.2kg BHT, then add 10kg infrared reflective material, disperse at high speed for 2.5 hours, stand for 24 hours, and filter to obtain the finished product.

[0036] Among them, the oily solvent is composed of the following components in parts by weight: 45 parts of epoxy soybean oil, 15 parts of triethylene glycol butyl ether, 15 parts of trieth...

Embodiment 3

[0038] Mix 65kg of linseed oil, take 32.5kg of linseed oil and heat it to 155℃, then slowly add 20kg of polyvinyl chloride resin, stir continuously at 500 rpm for dispersion, keep the temperature at 175℃, react for 180 minutes, then cool Adjust the pH to 7.5 at 90°C, then stir at 950 rpm, stir for 30 minutes, then cool and filter to obtain the mixed resin solution;

[0039] Take 10% of the miscible resin solution by weight of the entire miscible resin solution, dilute with the remaining 32.5kg of linseed oil, add 13kg of colorant to disperse, mix, and grind for 1.5 hours, then add the remaining miscible resin solution , 1.9kg of organic silicon and 0.1kg of BHT, then add 1kg of ultraviolet reflective material, disperse at high speed for 2.5 hours, stand for 26 hours, and filter to obtain the finished product.

[0040] Among them, the colorant is composed of the following components in parts by weight: 90 parts of light-fast 8 grade organic pigment and 10 parts of cinnabar.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com