Compound modification method for optimizing thermal performance of refuse derived fuel

A technology of waste-derived fuel and thermal performance, applied in the field of materials, can solve the problems of inability to deal with large quantities of municipal solid waste, large requirements for sorting, and not easy to be widely used, etc. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

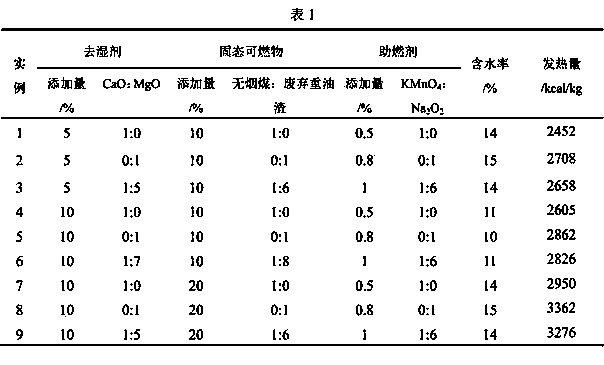

Embodiment 1

[0029] A compound modification method for optimizing thermal performance of garbage-derived fuels, comprising the steps of:

[0030] (1) Select domestic garbage with a moisture content of 20% after preliminary drying, and pulverize it to ensure that its particle size is not greater than 50mm, and add a desiccant CaO to it, and the added mass of the desiccant is 5wt% of the initial garbage , after stirring evenly, dry for 2 days;

[0031] (2) Add solid combustible anthracite and combustion enhancer KMnO to the dried garbage 4 , the addition of the solid combustibles is 10wt% of the initial garbage mass, the addition of the combustion accelerant is 0.5wt% of the initial garbage mass, and then mixed evenly, the garbage with a moisture content of 14wt% and a calorific value of 2452kcal / kg can be obtained derived fuel.

[0032] The moisture content and calorific value of the final product WDF were determined according to the standard biowaste sampling and physicochemical an...

Embodiment 2

[0034] A compound modification method for optimizing thermal performance of garbage-derived fuels, comprising the steps of:

[0035] (1) Select domestic garbage with a moisture content of 20% after preliminary drying, and crush it to ensure that its particle size is not greater than 50mm, and add a desiccant MgO to it, and the added mass of the desiccant is 5wt% of the initial garbage , after stirring evenly, dry for 1.5 days;

[0036] (2) Add solid combustible waste heavy oil residue and combustion aid Na to the dried garbage 2 o 2 , the addition of the solid combustibles is 10wt% of the initial garbage mass, the addition of the combustion accelerant is 0.8wt% of the initial garbage mass, and then mixed evenly, the garbage with a moisture content of 15wt% and a calorific value of 2708kcal / kg can be obtained derived fuel.

Embodiment 3

[0038] A compound modification method for optimizing thermal performance of garbage-derived fuels, comprising the steps of:

[0039] (1) Select domestic waste with a moisture content of 20% after preliminary drying, and crush it to ensure that its particle size is not greater than 50mm, and add desiccant CaO and MgO to it (the mass ratio of CaO to MgO is 1:5) , the added mass of the desiccant is 5wt% of the initial garbage, and after stirring evenly, it is dried for 1 day;

[0040] (2) Add solid combustibles and combustion accelerants to the dried garbage, and then mix them uniformly to obtain a garbage-derived fuel with a moisture content of 14wt% and a calorific value of 2658kcal / kg; wherein the amount of solid combustibles added It is 10wt% of the initial garbage quality, and is composed of waste heavy oil residue and anthracite according to a mass ratio of 1:6; 4 with Na 2 o 2 It is composed according to the mass ratio of 1:6.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

| Calorific value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com