Composite reinforced microalgae photobioreactor based on hollow light pipes

A photobioreactor and reactor technology, applied in photobioreactor, specific-purpose bioreactor/fermenter, bioreactor/fermenter combination, etc., can solve the problem of specific surface area reduction and gas-liquid mass transfer effect Variation, bubble coalescence and other problems, to achieve the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

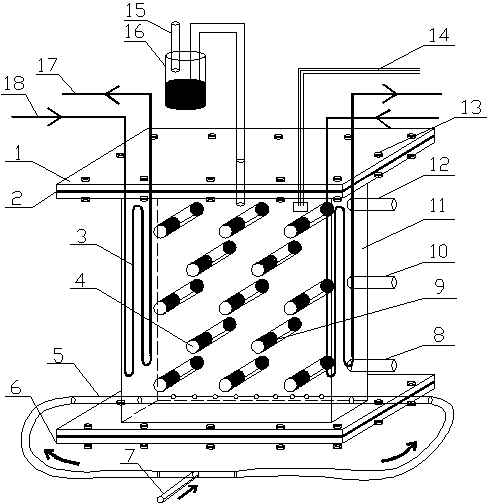

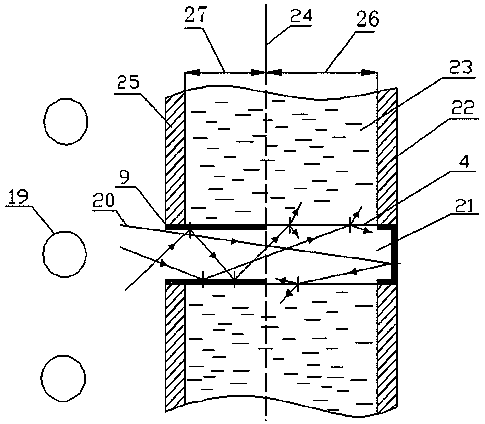

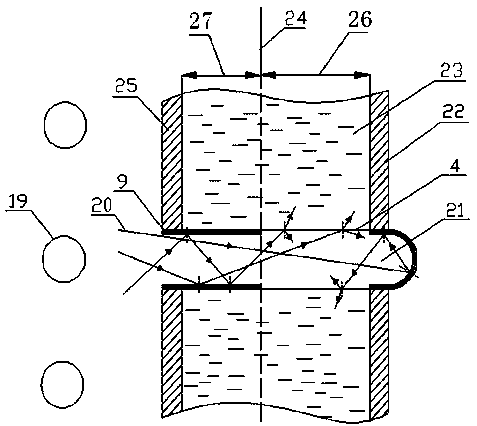

[0032] Such as figure 1 As shown, a composite enhanced microalgae photobioreactor based on a hollow light pipe, including a reactor top plate 1, a stainless steel serpentine tube 3, a hollow light pipe 4, a gas distributor 5, a reactor bottom plate 6, and a reactor Main body 11, fluorescent lamp light source 19, gas-liquid separation device 16 and pH, temperature, DO online monitoring device 14.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com