Comprehensive online real-time detection and control system for optical fiber pantograph

A real-time detection and control system technology, applied in the direction of current collectors, electric vehicles, measuring devices, etc., can solve the problems of inability to adjust the contact pressure between the pantograph and catenary, large errors, etc., to facilitate online real-time measurement and extend the use The effect of life and environmental corrosion resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

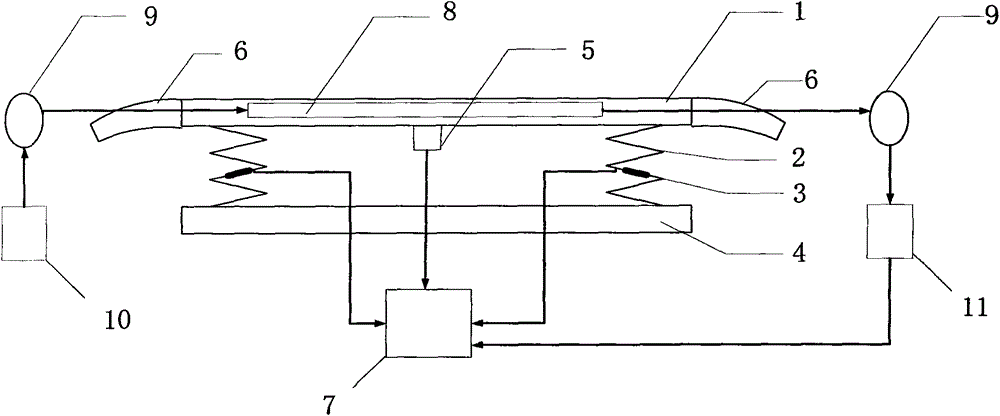

[0039] like figure 1 As shown, the comprehensive on-line real-time detection and control system of the fiber optic pantograph in this embodiment integrates the online real-time detection system of the fiber optic pantograph carbon sliding plate wear and the online real-time detection system of the fiber optic pantograph jacking pressure. The fiber-optic pantograph carbon slide wear online real-time detection system is used to detect the wear of the pantograph carbon slide [1], and adopts a transmission layout method. The online real-time detection system of fiber optic pantograph jacking pressure is used to measure the jacking pressure value F of the pantograph carbon slide[1] c . And the wear value of the pantograph carbon slide [1] and the jacking pressure F of the pantograph carbon slide [1] c Comprehensive comparative analysis, according to the preset criteria output the feedback signal used to control the airbag control valve to adjust the lifting pressure F of the pant...

Embodiment 2

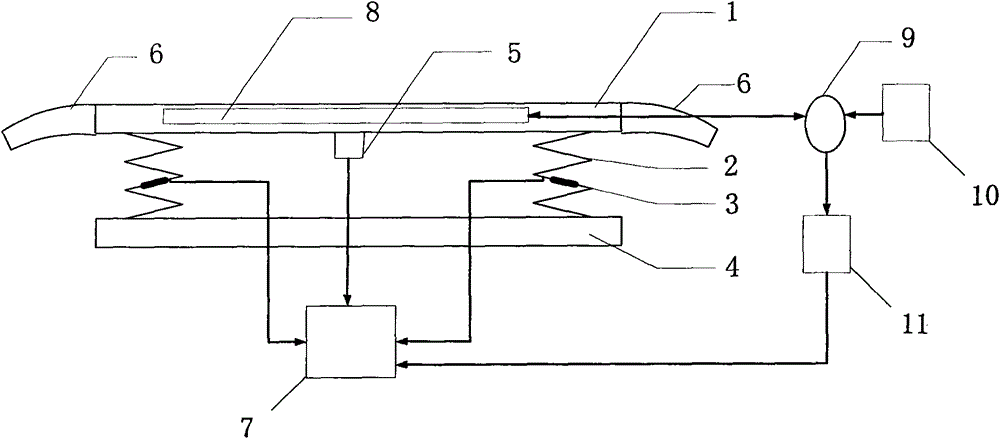

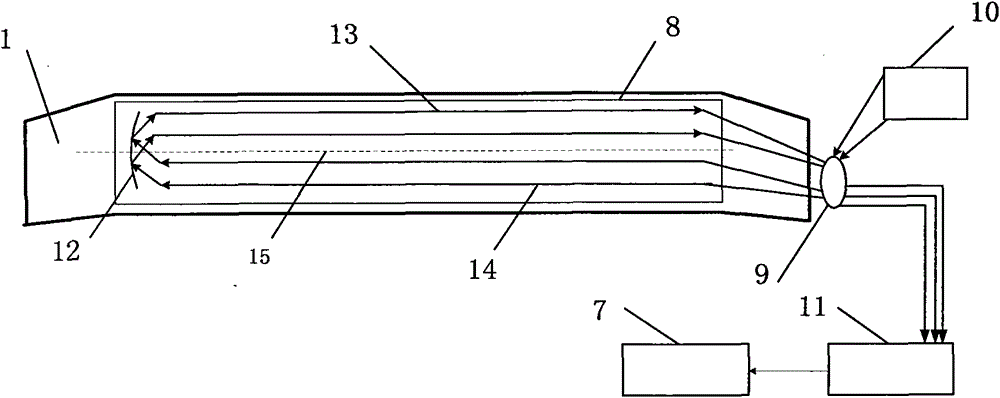

[0058] like figure 2 , 3 As shown, the comprehensive on-line real-time detection and control system of the fiber optic pantograph in this embodiment integrates the online real-time detection system of the fiber optic pantograph carbon sliding plate wear and the online real-time detection system of the fiber optic pantograph jacking pressure. The fiber-optic pantograph carbon slide wear online real-time detection system is used to detect the wear of the pantograph carbon slide [1], and adopts a reflective layout. The online real-time detection system of fiber optic pantograph jacking pressure is used to measure the jacking pressure value F of the pantograph carbon slide[1] c . And the wear value of the pantograph carbon slide [1] and the jacking pressure F of the pantograph carbon slide [1] c Comprehensive comparison and analysis, according to the preset criteria output the feedback signal used to control the solenoid valve and timely adjust the lifting pressure F of the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com