Metal cap production line information service method and system

A technology of information service and production line, applied in the field of information service method and system of metal cover production line, can solve the problems such as difficult direct mutual transmission of PLC internal data, incompatibility of programming tools, long production line, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The specific embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

[0058] Process flow of the present invention is as follows:

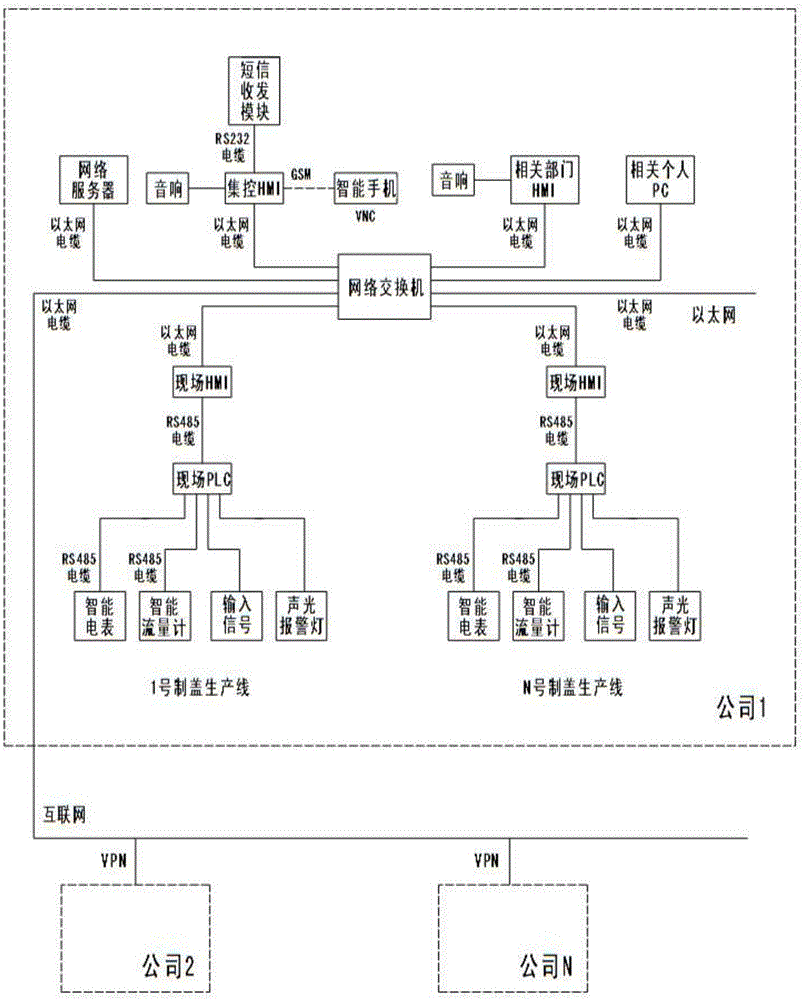

[0059] One, set up as figure 1 The information service system of the metal cap production line shown.

[0060] 1. The composition of the system: the system consists of smart meters, natural gas smart flow meters, sound and light alarm lights, RS485 cables, on-site PLC, on-site HMI, SMS transceiver modules, RS232 cables, centralized control HMI, audio, smart phones, related department HMI, Relevant personal PCs, Ethernet cables, network switches, and network servers are composed.

[0061] 2. Hardware connection of the system: On-site HMI, centralized control HMI, relevant department HMI, relevant personal PCs, and network servers are respectively connected to the network switch through their respective network interfaces using Ethernet cables to form an Ethernet network; the SMS ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com