Preparation method and application of tungstate photocatalytic material

A photocatalytic material, tungstate technology, applied in the field of preparation of tungstate photocatalytic materials, can solve the problem of low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0012] (1) will Bi 2 o 3 , Na 2 CO 3 and WO 3 Mix according to stoichiometric ratio.

[0013] (2) After grinding the mixture with ethanol, it was preheated at 650°C for 12h.

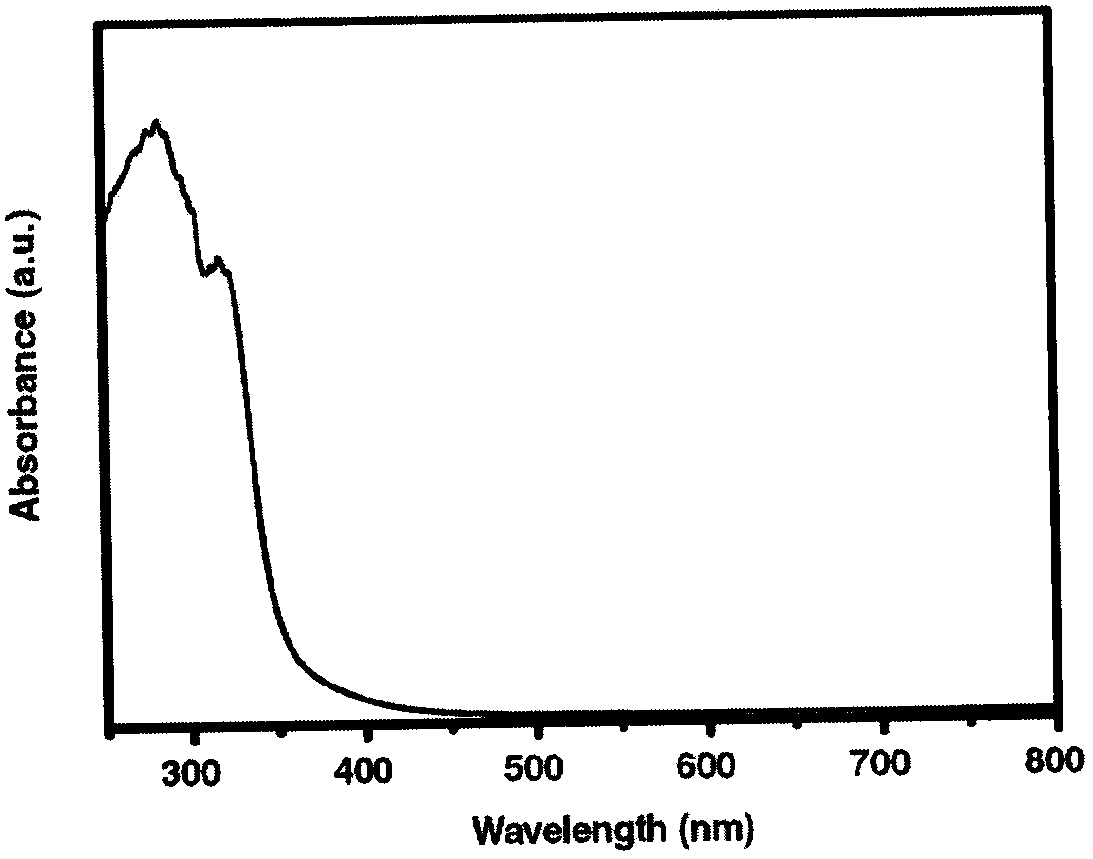

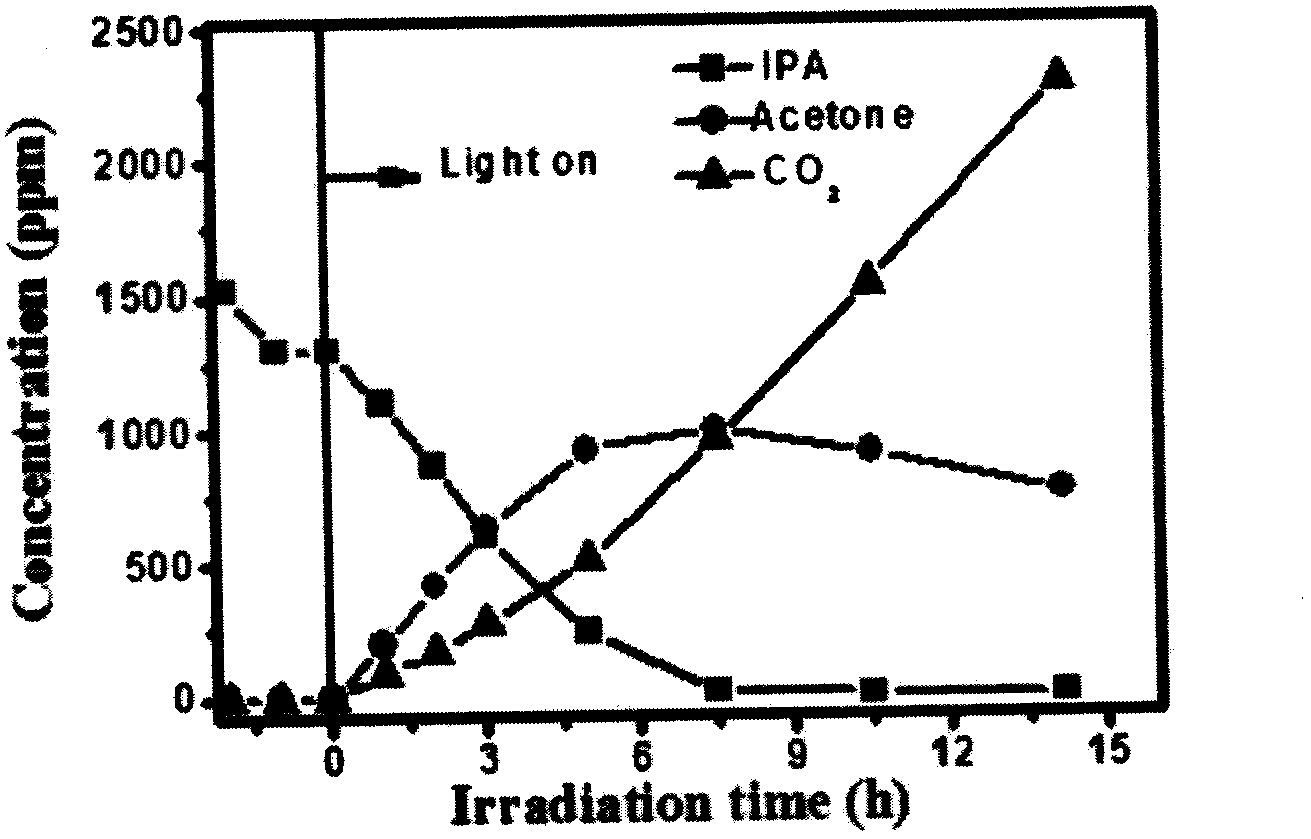

[0014] (3) After regrinding, calcining at 800°C for 10h.

[0015] The invention provides a preparation method of a tungstate photocatalytic material and its photocatalytic degradation performance of organic matter. The degradation rate of isopropanol was used to evaluate the degradation performance of photocatalytic organic matter. The degradation process of the photocatalytic reaction of isopropanol is: first, isopropanol is converted into an intermediate product (acetone); then, acetone is oxidized to CO 2 and H 2 O. Because, in the initial stage, isopropanol mainly undergoes the reaction of being degraded into acetone. Therefore, the generation rate of acetone in the initial stage is often used to evaluate the photocatalytic performance. This scheme is further described by the following exa...

specific Embodiment approach 2

[0016] (1) 0.400g of NaBi (WO 4 ) 2 The powder sample is evenly dispersed on the bottom of a glass container, and the glass container is placed on the bottom of a high borosilicate glass container (this is a closed container).

[0017] (2) After sealing the reactor, inject a certain amount of isopropanol into the reactor using a gas sampler. The reactor was placed in a dark place for 2 h to allow the system to reach adsorption-desorption equilibrium.

[0018] (3) The light source is a xenon lamp, which is irradiated on the surface of the material through the cooling circulating water system (to eliminate the thermal effect caused by infrared rays).

[0019] (4) Place the reactor under the light source to start the reaction, and regularly take samples from the reaction system, and use a gas chromatograph to detect the concentrations of isopropanol, acetone and carbon dioxide.

[0020] After reaching the equilibrium of adsorption and desorption, the reaction begins, the initi...

specific Embodiment approach 3

[0021] Specific embodiment three: different from specific embodiment two, the photocatalytic material powder used in step (1) is WO 3 , after the reaction was carried out for 3h, the production rate of acetone was 120ppm / h.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com