Catalyst used in HFC-245fa cracking and combined production of HFC-1234ze and HFC-1234yf, and preparation method thereof

A technology of hfc-1234yf and hfc-245fa, applied in the field of chemical catalyst and its preparation, can solve the problems of less than 20% conversion rate, large amount of HF, complicated catalyst preparation process, etc. The effect of stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

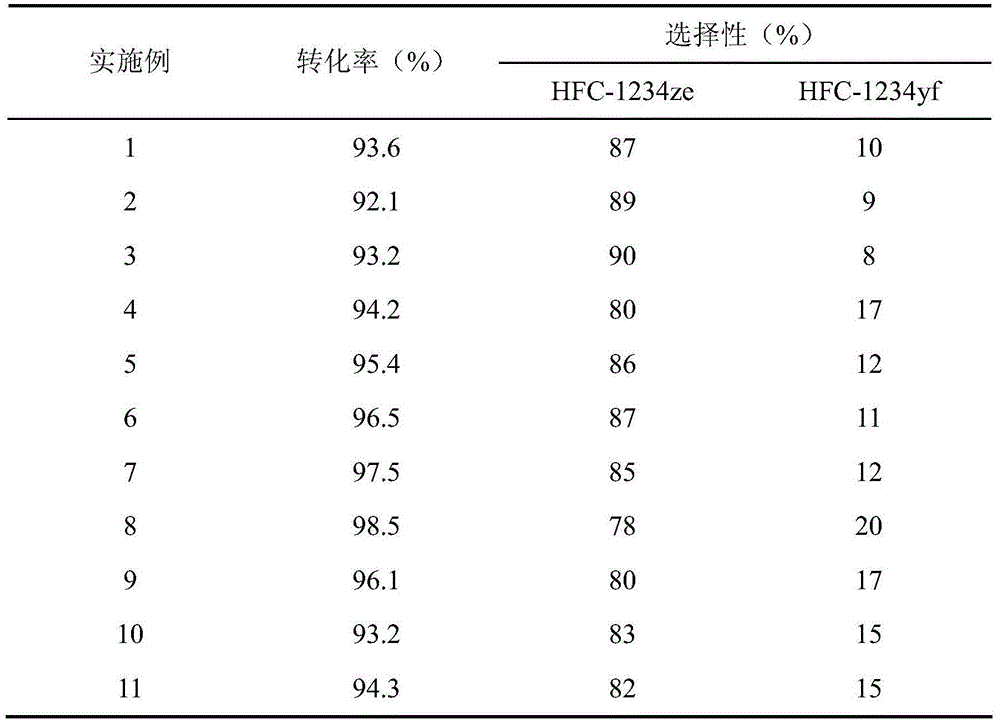

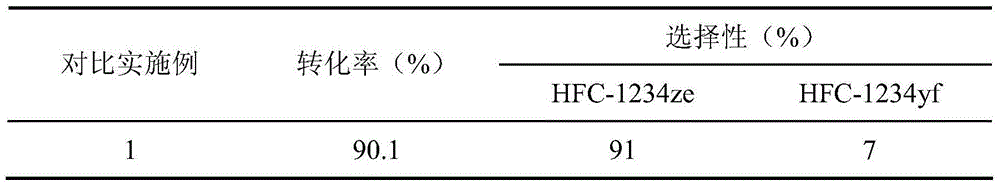

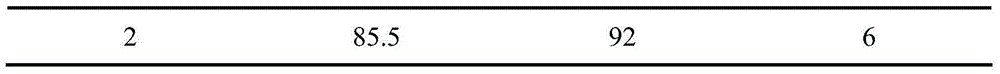

Examples

Embodiment 1

[0024] (1) Preparation of Cr by precipitation method 2 o 3 :

[0025] ①CrCl 3 The solution is mixed with ammonia water to prepare Cr(OH) 3 Precipitated, filtered, dried under nitrogen at 120°C, and then calcined under nitrogen at 500°C for 4 hours to obtain Cr 2 o x (x=3.1);

[0026] ②Cr 2 o x Reduction under hydrogen atmosphere at 400°C for 1 hour yields Cr 2 o 3 ;

[0027] (2) Preparation of catalyst by mechanical mixing method:

[0028] ① Weigh Cr 2 o 3 , β-AlF 3 , Ni(OH) 2 、Ag 2 O, making Cr 2 o 3 and β-AlF 3 The molar ratio of substances is 9:1, Ni and Ag account for Cr respectively 2 o 3 and β-AlF 3 0.5% and 0.1% of the total mass, mechanically mixed, compressed into tablets;

[0029] ②Finally, it is roasted at 400°C under nitrogen atmosphere for 4 hours, and then reduced at 400°C under hydrogen atmosphere for 1 hour to obtain the Ni-Ag-Cr of the present invention.2 o 3 -AlF 3 mixture catalyst.

[0030] In a self-made stainless steel tube fixed-b...

Embodiment 2

[0032] (1) Preparation of Cr by precipitation method 2 o 3 :

[0033] ①CrCl 3 The solution is mixed with ammonia water to prepare Cr(OH) 3 Precipitated, filtered, dried under nitrogen at 120°C, and then calcined under nitrogen at 500°C for 4 hours to obtain Cr 2 o x (x=3.1);

[0034] ②Cr 2 o x Reduction under hydrogen atmosphere at 400°C for 1 hour yields Cr 2 o 3 ;

[0035] (2) Preparation of catalyst by mechanical mixing method:

[0036] ① Weigh Cr 2 o 3 , β-AlF 3 , Ni(OH) 2 、Ag 2 CO 3 , making Cr 2 o 3 and β-AlF 3 The molar ratio of substances is 3:7, Ni and Ag account for Cr respectively 2 o 3 and β-AlF 3 0.5% and 0.1% of the total mass, mechanically mixed, compressed into tablets;

[0037] ②Finally, it is roasted at 400°C under nitrogen atmosphere for 4 hours, and then reduced at 400°C under hydrogen atmosphere for 1 hour to obtain the Ni-Ag-Cr of the present invention. 2 o 3 -AlF 3 mixture catalyst.

[0038] In a self-made stainless steel tube ...

Embodiment 3

[0040] (1) Preparation of Cr by precipitation method 2 o 3 :

[0041] ①CrCl 3 The solution is mixed with ammonia water to prepare Cr(OH) 3 Precipitated, filtered, dried under nitrogen at 120°C, and then calcined under nitrogen at 500°C for 4 hours to obtain Cr 2 o x (x=3.1);

[0042] ②Cr 2 o x Reduction under hydrogen atmosphere at 400°C for 1 hour yields Cr 2 o 3 ;

[0043] (2) Preparation of catalyst by mechanical mixing method:

[0044] ① Weigh Cr 2 o 3 , β-AlF 3 、NiCO 3 、Ag 2 CO 3 , making Cr 2 o 3 and β-AlF 3 The molar ratio of substances is 5:5, Ni and Ag account for Cr respectively 2 o 3 and β-AlF 3 0.5% and 0.1% of the total mass, tablet molding;

[0045] ②Finally, it is roasted at 400°C under nitrogen atmosphere for 4 hours, and then reduced at 400°C under hydrogen atmosphere for 1 hour to obtain the Ni-Ag-Cr of the present invention. 2 o 3 -AlF 3 mixture catalyst.

[0046] In a self-made stainless steel tube fixed-bed reactor with an inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com