Polystyrene foam aggregate concrete insulation building block

A technology of polystyrene foam and thermal insulation blocks, which is applied in the field of polystyrene foam aggregate concrete thermal insulation blocks, can solve the problem that it is difficult to take into account the strength of masonry, the production cost of the manufacturing process, the difficulty in meeting the required strength of masonry, and the market Reduced competitiveness and other issues, to achieve the effect of environmental protection, light weight, and light weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described below in conjunction with the examples, but the protection scope of the present invention is not limited thereto.

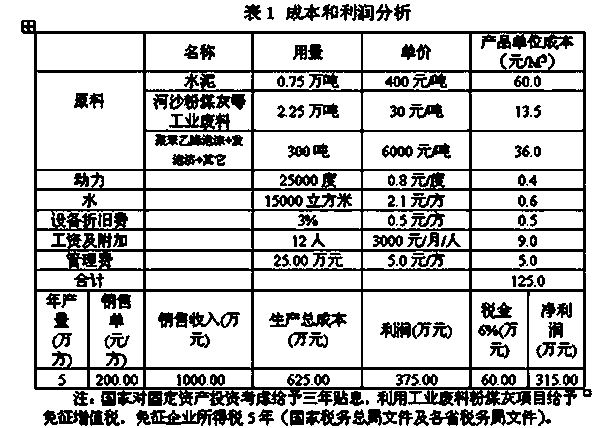

[0041] To produce 1m 3 Taking polystyrene foam aggregate concrete insulation block as an example, the specific complete production process is given here as follows:

[0042] (1) Foamed plastic products crushing: use a crusher (when the amount is small, manual crushing can also be used) to crush polystyrene foamed plastic products into particles with a particle size of ≤ 1cm to obtain polystyrene foamed aggregates;

[0043] (2) Preparation of mixed slurry: 82.5kg of water, 150kg of cement (ordinary Portland cement or slag Portland cement with a strength grade of 42.5, place of origin: Hunan Hengyu Building Materials Co., Ltd. / Shuangma Industrial Park, Xiangtan City, Hunan ), 450kg of river sand or fly ash, 0~15kg of tackifier (you can not add it, only add it when the plastic viscosity is too bad), 2.25kg of e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com