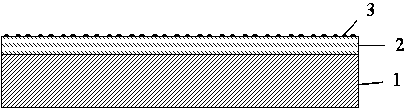

Anti-fingerprint transparent hardening film for touch screen

An anti-fingerprint and touch screen technology, which is applied in the direction of chemical instruments and methods, coatings, layered products, etc., can solve the problems of obvious fingerprints, loss of anti-fingerprints, difficulty in preventing fingerprint pollution, etc., and achieves remarkable effects, high definition, Remarkable effect of anti-fingerprint pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] 1. Preparation of silica dispersion:

[0036] Mix 50 parts by weight of nano-silica [Degussa R-972] and 50 parts by weight of propylene glycol monomethyl ether, disperse on a high-speed mixer for 30 minutes, then use a ball mill for 10 hours, and filter to obtain the average particle size. A silica dispersion with a diameter of 0.1 μm and a solid content of 50%.

[0037] 2. Preparation of Hard Coating Solution

[0038] 6197H 50 parts by weight,

[0039] Initiator 184 3 parts by weight,

[0040] Silica dispersion 100 parts by weight,

[0041] Modified perfluoropolyether AF-01 0.2 parts by weight,

[0042] Leveling agent Byk-377 0.05 parts by weight,

[0043] 30 parts by weight of propylene glycol monomethyl ether,

[0044] Dissolve 50 parts by weight of aliphatic urethane acrylate prepolymer 6197H [Changxing Chemical; functionality 6] into 30 parts by weight of propylene glycol monomethyl ether solvent, add 0.05 parts by weight of polyether-modified polydimethylsil...

Embodiment 2

[0048] 1. Preparation of alumina dispersion:

[0049] 50 parts by weight of nano-alumina [model XZ-L14, Hefei Xiangzheng Chemical Technology Co., Ltd.] and 50 parts by weight of methyl isobutyl ketone were mixed together, dispersed on a high-speed mixer for 30 minutes, and then ball milled with a ball mill for 7 hours, filtered to obtain an alumina dispersion with an average particle size of 0.3 μm and a solid content of 50%.

[0050] 2. Preparation of Hard Coating Solution

[0051] UXE1000 30 parts by weight,

[0052] 20 parts by weight of PETA,

[0053] Initiator 1173 8 parts by weight,

[0054] Aluminum oxide dispersion 80 parts by weight,

[0055] Modified perfluoropolyether DAC-HP 0.5 parts by weight,

[0056] Leveling agent Byk-354 0.3 parts by weight,

[0057] 40 parts by weight of methyl isobutyl ketone,

[0058] Dissolve 30 parts by weight of aliphatic urethane acrylate prepolymer UXE1000 [manufactured by Huayao Chemical (Wuxi) Co., Ltd., functionality 4] and 2...

Embodiment 3

[0062] 1. Preparation of silica dispersion:

[0063] 50 parts by weight of nano silica [Degussa R-972] and 50 parts by weight of butanone were mixed together, dispersed on a high-speed mixer for 30 minutes, then ball milled for 4 hours with a ball mill, and filtered to obtain an average particle size of 0.5 μm, 50% solid content silica dispersion.

[0064] 2. Preparation of Hard Coating Solution

[0065] 50 parts by weight of EM-2411,

[0066] Initiator 184 2 parts by weight,

[0067] Silica dispersion 60 parts by weight,

[0068] Modified perfluoropolyether AF-01 1 part by weight,

[0069] Leveling agent Levaslip 432 0.2 parts by weight,

[0070] Butanone 50 parts by weight,

[0071] Dissolve 50 parts by weight of ethoxylated pentaerythritol tetraacrylate monomer EM-2411 [Changxing Chemical, functionality 4] into 50 parts by weight of methyl ethyl ketone solvent, add 0.2 parts by weight of polydimethylsiloxane skeleton structure Leveling agent Levaslip 432 [manufacture...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com