Full-fabricated cross concrete combining joint

A combination of joints and concrete technology, applied in the direction of architecture, building structure, etc., can solve the problems of insufficient prefabricated structure anti-seismic integrity and professional research on design and construction management, poor technical and economic efficiency, etc., to achieve fast construction speed, convenient construction, The effect of high bearing capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in combination with technical solutions and with reference to the accompanying drawings.

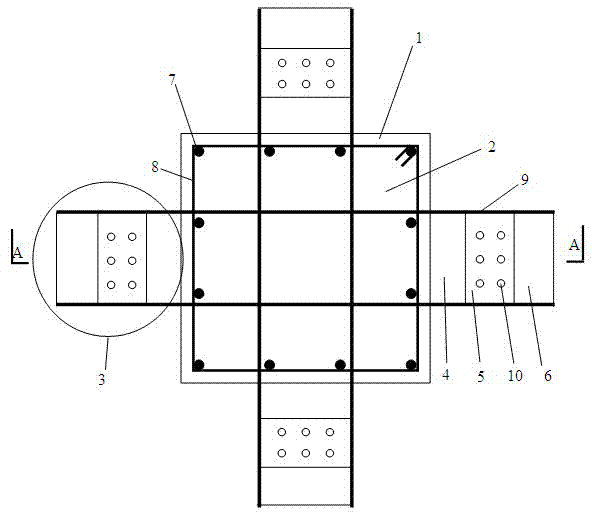

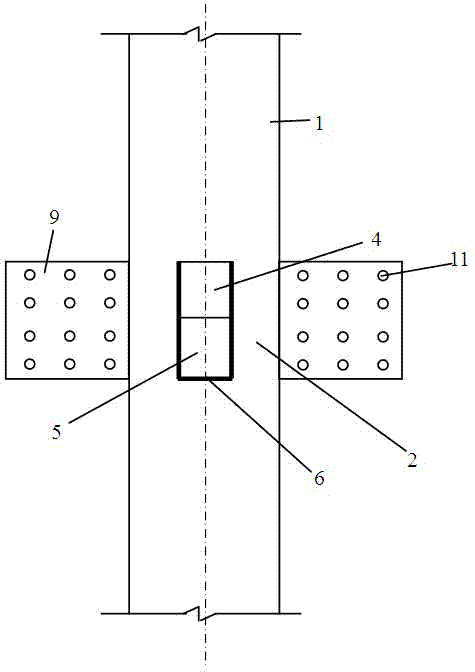

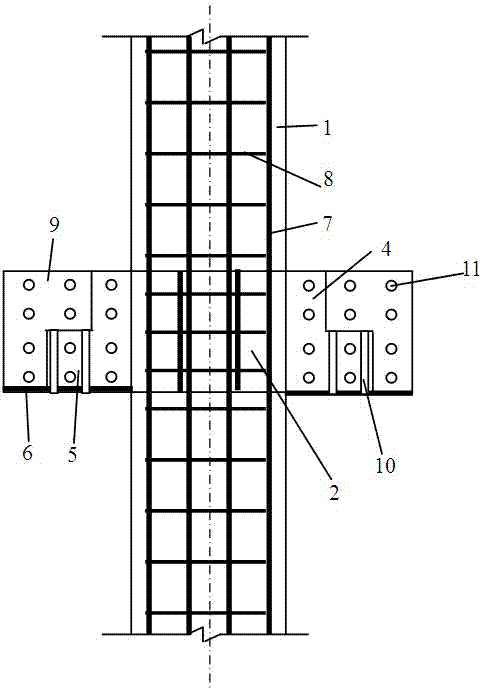

[0019] The fully assembled cross-shaped concrete composite node proposed by the present invention is as follows: Figure 1~Figure 3 shown.

[0020] The whole device mainly consists of precast concrete column 1, precast concrete beam-column joint core area 2, precast concrete beam 3, precast concrete beam upper platform 4, precast concrete beam lower platform 5, precast concrete beam lower steel plate 6, precast concrete column The longitudinal reinforcement 7, the prefabricated concrete column stirrup 8, the prefabricated concrete beam piercing steel plate 9, the vertical screw hole 10 for the assembly of the concrete beam and the horizontal screw hole 11 for the assembly of the concrete beam, etc. The precast concrete beam-through steel plates 9 pass through the core area 2 of the precast concrete beam-column joints, and ar...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com