Chained SVG module voltage-equalizing control method and circuit

A voltage equalization control, chain technology, applied in electrical components, flexible AC transmission systems, output power conversion devices, etc., can solve problems such as inability to achieve electrical insulation, complex external circuits, and inability to achieve voltage equalization effects The effect of reducing cost and control complexity, fewer components, and ease of mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with accompanying drawing description and specific embodiment:

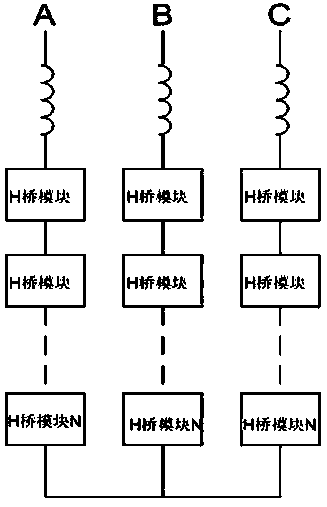

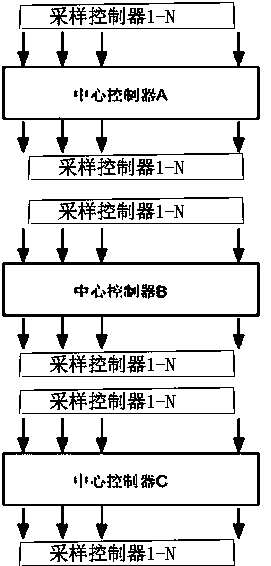

[0027] Such as figure 1 It is a structure diagram of a chained SVG star connection mode. Each phase link has multiple H-bridge modules with the same structure connected in series. The higher the voltage level, the more the number of cascaded H-bridge modules, such as 6KV chained The SVG star link mode can be cascaded with 8 H-bridge modules, while the 10KV chained SVG star link mode requires 12 H-bridge modules to be cascaded.

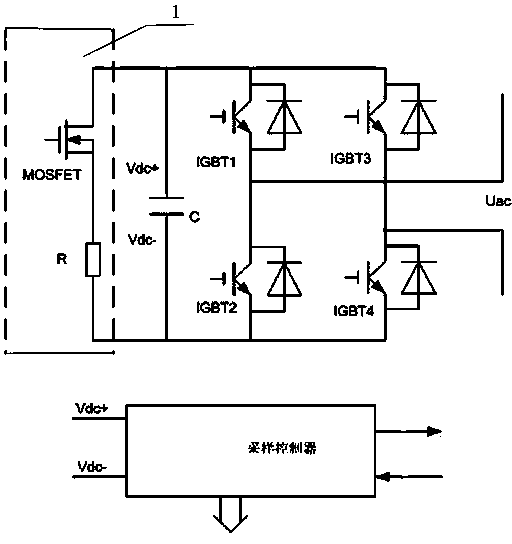

[0028] Chained SVG power module voltage equalization control method:

[0029] a. Collect the DC bus voltage value of the H-bridge module in the single-phase power module;

[0030] b. Calculate the average value of the multiple DC bus voltages collected;

[0031] c. The average value is compared with the real-time voltage value of the H-bridge module to control the power consumption of the power module...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com