Flavored corn oil as well as preparation method thereof

A corn oil and flavor technology, applied in the field of edible oil, achieves the effects of good thermal stability, increased nutrient components, and increased linoleic acid content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

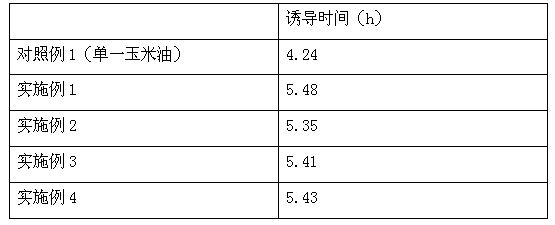

Examples

Embodiment 1

[0065] Prepare various raw materials by following parts by weight:

[0066] Corn Germ Oil 100 Garlic Essential Oil 5

[0067] Fennel essential oil3 Coriander essential oil3

[0068] Ginger essential oil5 Sesame oil4

[0069] Star Anise Essential Oil3 Grape Seed Oil4

[0070] Perilla oil 3 Mustard oil 3

[0071] Pepper Oil 3 Lard 8

[0072] Sugars 2 Amino Acids 2.

[0073] After mixing and stirring corn germ oil, lard, sugar, and amino acids, heat to about 140°C, react for 3 minutes, and let it dry to about 55°C;

[0074] Then garlic essential oil, fennel essential oil, coriander essential oil, ginger essential oil, sesame oil, star anise essential oil, grape seed oil, perilla oil, mustard oil, pepper oil and the oil obtained in the above steps are mixed at a temperature of about 55°C.

Embodiment 2

[0076] Prepare various raw materials by following parts by weight:

[0077] Corn Germ Oil 60 Garlic Essential Oil 1

[0078] Fennel essential oil1 Coriander essential oil1

[0079] Ginger essential oil 1 Sesame oil 1

[0080] Anise essential oil1 Grape seed oil1

[0081] Perilla Oil 1 Mustard Oil 1

[0082] Pepper Oil 1 Lard 1

[0083] Sugar 1 Amino Acid 1.

[0084] After mixing and stirring corn germ oil, lard, sugar and amino acid, heat to about 120°C, react for 1min, and let it dry to about 50°C;

[0085] Then garlic essential oil, fennel essential oil, coriander essential oil, ginger essential oil, sesame oil, star anise essential oil, grape seed oil, perilla oil, mustard oil, pepper oil and the oil obtained in the above steps are mixed at a temperature of about 50°C.

Embodiment 3

[0087] Prepare various raw materials by following parts by weight:

[0088] Corn Germ Oil 150 Garlic Essential Oil 8

[0089] Fennel essential oil5 Coriander essential oil5

[0090] Ginger essential oil 8 Sesame oil 6

[0091] Star Anise Essential Oil5 Grape Seed Oil8

[0092] Perilla oil 5 Mustard oil 4

[0093] Pepper Oil 6 Lard 10

[0094] Sugar 4 Amino Acid 4.

[0095] After mixing and stirring corn germ oil, lard, sugar, and amino acids, heat to about 160°C, react for 4 minutes, and air to about 60°C;

[0096] Then garlic essential oil, fennel essential oil, coriander essential oil, ginger essential oil, sesame oil, star anise essential oil, grape seed oil, perilla oil, mustard oil, pepper oil and the oil obtained in the above steps are mixed at a temperature of about 60°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com