Reaction kettle device capable of controlling synthesis temperature of accelerant 2-mercaptobenzothiazole (MBT)

A reaction kettle and accelerator technology, applied in the field of rubber vulcanization accelerator MBT production, can solve the problems of reducing MBT yield and purity, affecting reaction yield, prone to side reactions, etc., to achieve sensitive temperature changes and enhance internal mass transfer , the effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

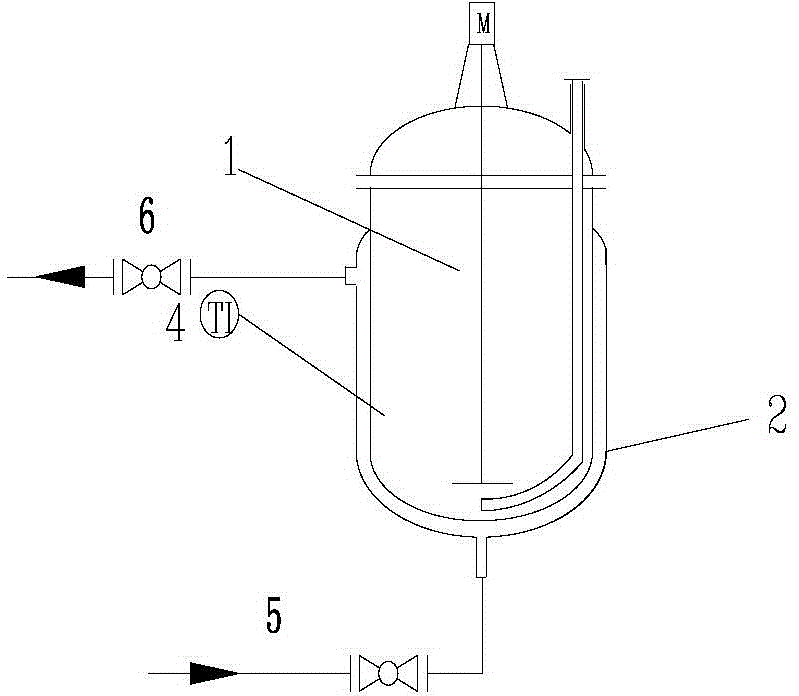

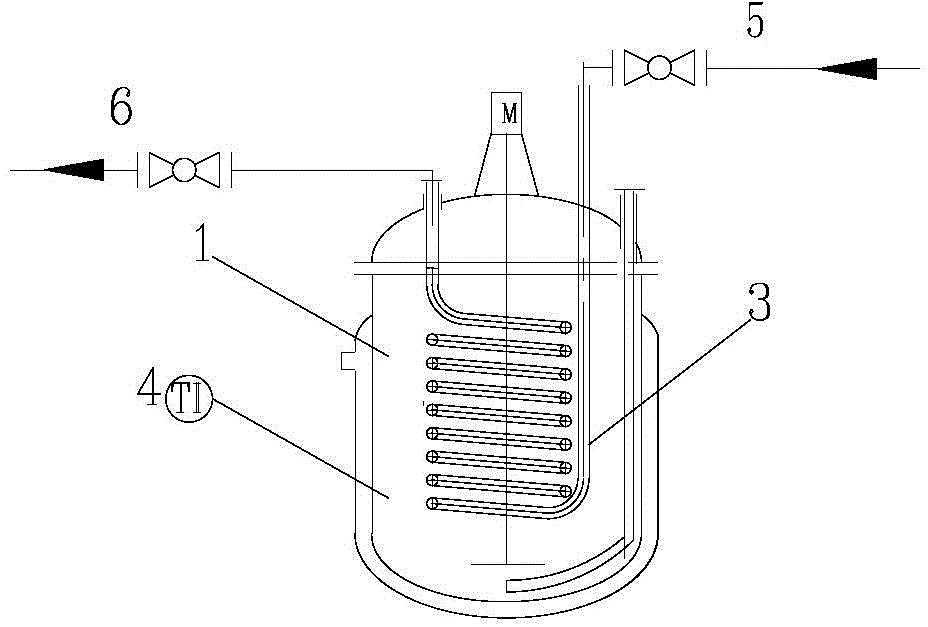

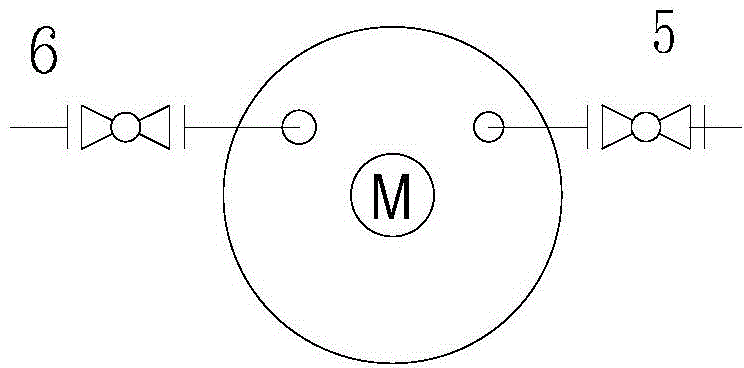

[0012] Refer to the manual figure 2 The present invention will be described in detail below.

[0013] The improvement to the autoclave of the present invention includes a high-pressure reactor 1 , a heat conduction oil coil 3 and a reactor thermometer 4 . The length of the coil is 1 / 2-2 / 3 of the length of the kettle body, and the diameter of the coil is 0.7-0.9 times the diameter of the kettle body. Line 6 is connected.

[0014] After applying this system in MBT production, the temperature of the heat transfer oil is controlled at about 240°C, the reaction temperature is controlled at 255°C, the fluctuation range is 3°C, and the reaction time is 120min, the product yield can reach 89%.

[0015] During the reaction process, the heat conduction oil is directly passed into the reactor, which reduces the heat transfer resistance and improves the heat transfer efficiency. At the same time, adding coils inside the reactor enhances the internal mass transfer. The internal temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com