Spray absorber type carbonization reaction device for alkali balance in indigo production

A technology of carbonization reaction and indigo, applied in chemistry/physics/physicochemical fixed reactors, organic chemistry, carbonate preparations, etc., can solve the problems of polluting the environment, wasting potassium resources, potassium loss, etc., and achieve resource utilization High, low equipment resistance, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

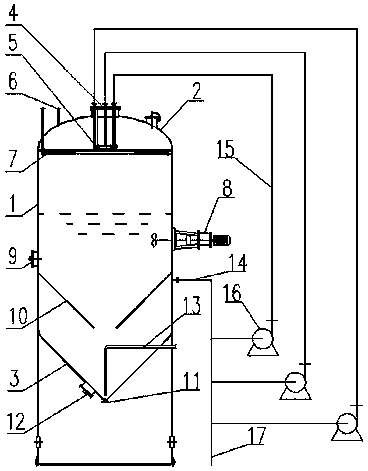

[0022] The present invention will be further described below in conjunction with drawings and embodiments.

[0023] figure 1 As shown, a spray absorption tower carbonization reaction device for alkali balance in indigo production includes a tower body 1, an upper head 2, a cone head 3, a spray head 4, a nozzle 5, an air inlet 6, and a cleaning plate Pipe 7, propulsion type agitator 8, manhole 9, inner cone 10, drain port 11, inspection port 12, bottom insertion discharge pipe 13, circulation suction pipe 14, circulation pipe 15, circulation pump 16 and liquid inlet pipe 17. The spray head 4 is arranged in the upper head 2, and the spray head 4 is a structure with a plurality of nozzles 5 uniformly distributed on the same horizontal plane, and the downward spray angle of the spray head 4 is 120° of central symmetry;

[0024] The upper head 2 is provided with an air inlet 6 higher than the spray head 4, the upper head 2 is packaged on the top of the tower body 1, the cone ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com