Method for improving vulcanization bonding strength of natural rubber elastic element and metal reinforcing element of flexible joint

A technology of metal reinforcement and natural rubber, applied in the field of vulcanized bonding strength of metal reinforcement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

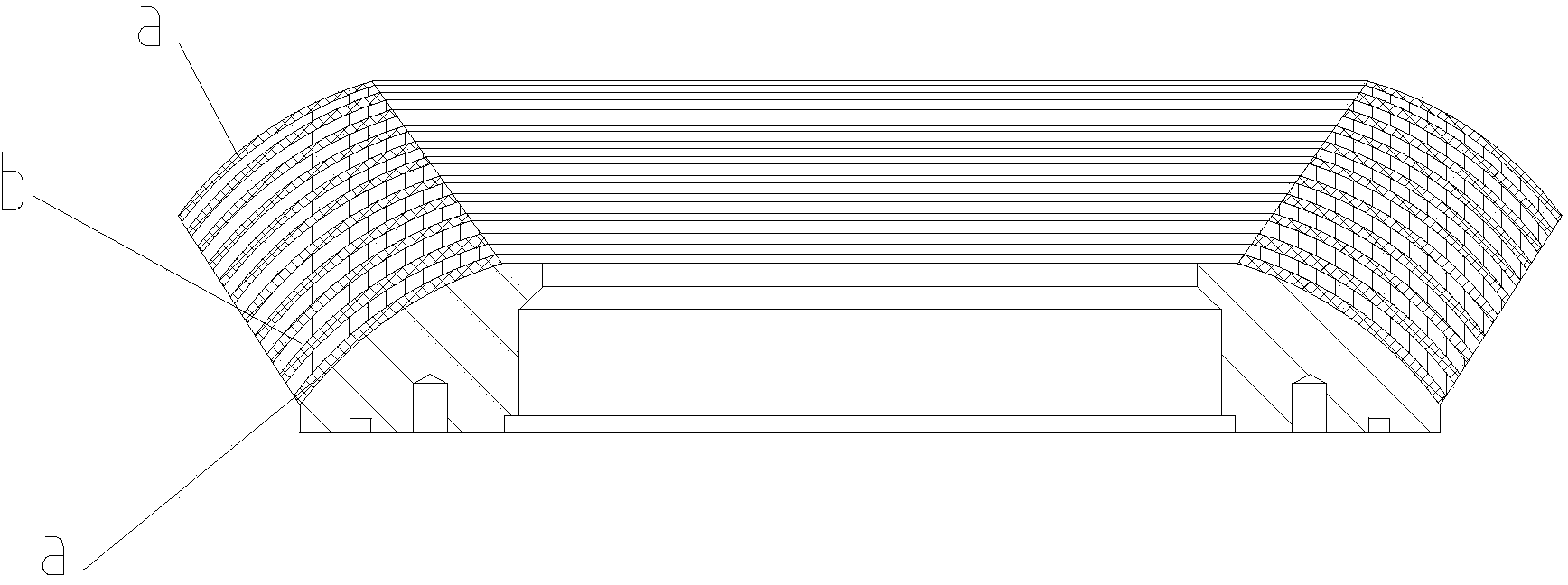

[0024] For a certain type of flexible joint, the complex of elastic parts and metal reinforcements is as follows: figure 1 As shown, it is made of 11 layers of elastic parts a and 10 layers of metal reinforcement b alternately vulcanized and bonded. The main material of elastic part a is natural rubber with a thickness of 2.2mm. Metal reinforcement b is made of 30CrMnSiA forgings with a thickness of 3mm, the method for the vulcanization bonding strength of the natural rubber elastic part of the flexible joint and the metal reinforcement part, including the following steps in turn:

[0025] 1) According to the design requirements of the flexible joint structure, the metal reinforcement is processed into a metal sheet of δ3×20×70 (mm), and the natural rubber elastic part is cut into a δ2.2×20×70 (mm);

[0026] 2) Sandblast the metal plate on both sides. Before sandblasting, put the metal plate into acetone to clean it to remove surface oil. After sandblasting, the surface is req...

Embodiment 2

[0034] For a certain type of flexible joint, it is made by alternately bonding 10 layers of elastic parts and 9 layers of metal reinforcements. The main material of the elastic parts is natural rubber with a thickness of 2mm. The material of the metal parts is 45# steel with a thickness of 2.5mm. The method for the vulcanization bonding strength of the natural rubber elastic part and the metal reinforcement part of the flexible joint includes the following steps in sequence:

[0035] 1) According to the design requirements of the flexible joint structure, the metal reinforcement is processed into a metal sheet of δ2.5×20×70 (mm), and the natural rubber elastic part is cut into a δ2.0×20×70 (mm);

[0036] 2) Double-sided sandblasting of the metal plate: before sandblasting, put the metal plate into acetone to clean, remove the surface oil, after sandblasting, the surface is required to be evenly fluffed to reveal the metallic luster;

[0037] 3) Put the sandblasted metal plate ...

Embodiment 3

[0044] For a certain type of flexible joint, it is made of 11 layers of elastic parts and 10 layers of metal reinforcements alternately vulcanized and bonded. The main material of the elastic parts is natural rubber with a thickness of 2mm. The reinforcement is made of 30CrMnSiA forgings with a thickness of 2.5mm. , the method for the vulcanized bonding strength of the natural rubber elastic part and the metal reinforcement part of the flexible joint, comprising the following steps in turn:

[0045] 1) According to the design requirements of the flexible joint structure, the metal reinforcement is processed into a metal sheet of δ2.6×20×65 (mm), and the natural rubber elastic part is cut into a δ2.2×20×65 (mm);

[0046] 2) Sandblast the metal plate on both sides. Before sandblasting, put the metal plate into acetone to clean it to remove surface oil. After sandblasting, the surface is required to be evenly fluffed to reveal the metallic luster;

[0047] 3) Put the sandblasted ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com