Vertical multi-cylinder or single-cylinder hydraulic briquette extruder with helical impeller feeding

A technology of helical impeller and coal rod machine, which is applied to material forming presses, punching machines, presses, etc., can solve the problems of poor strength and brittleness of coal rods, low output of a single unit, and long unit time. Achieve the effect of small footprint, automatic control, and improved power factor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

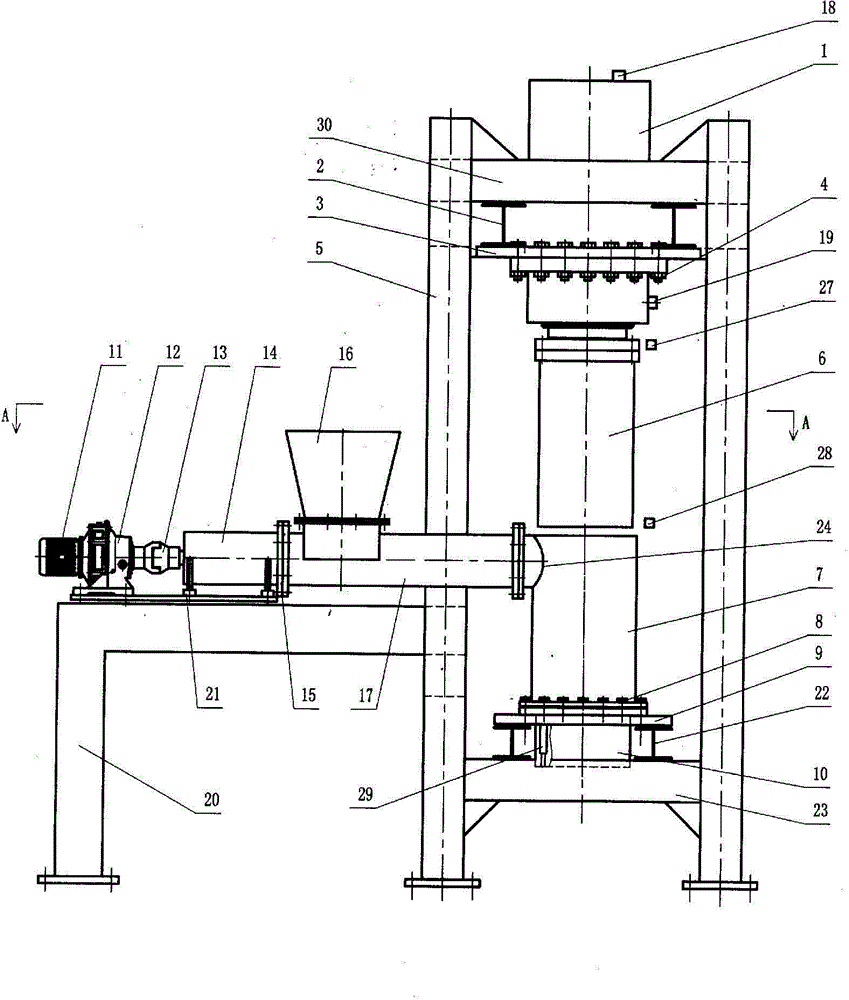

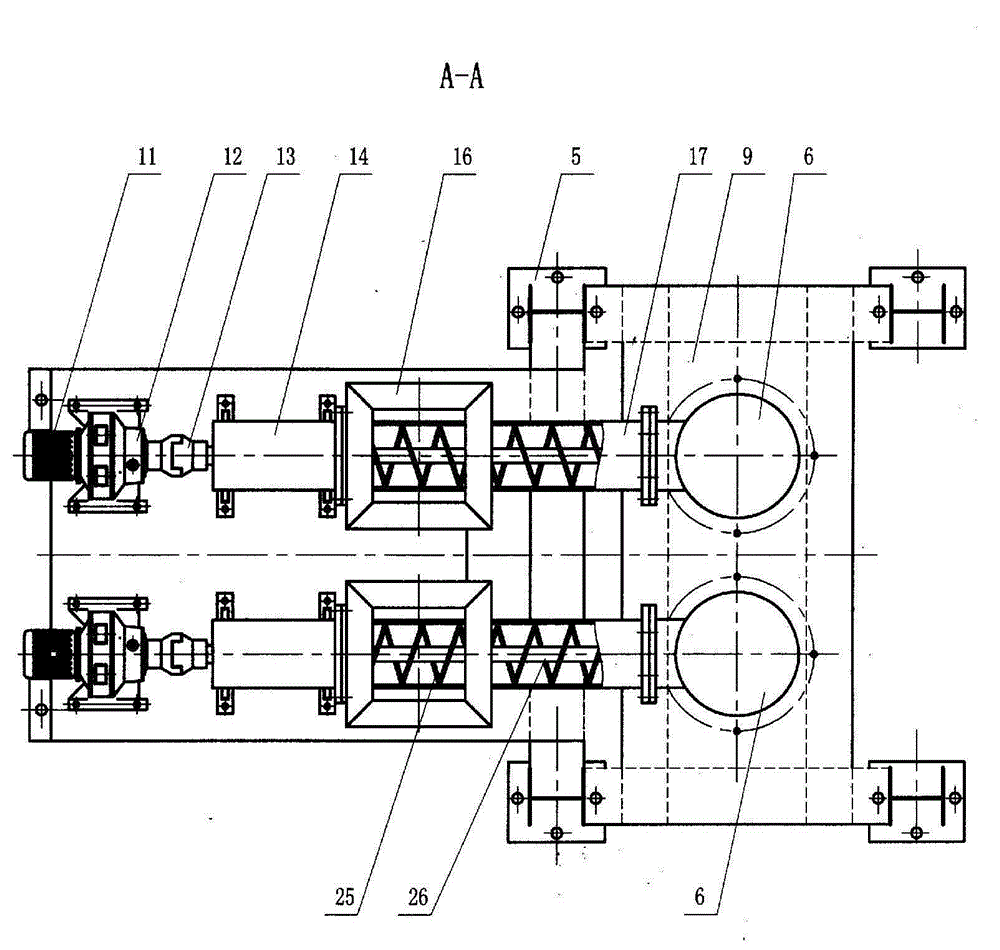

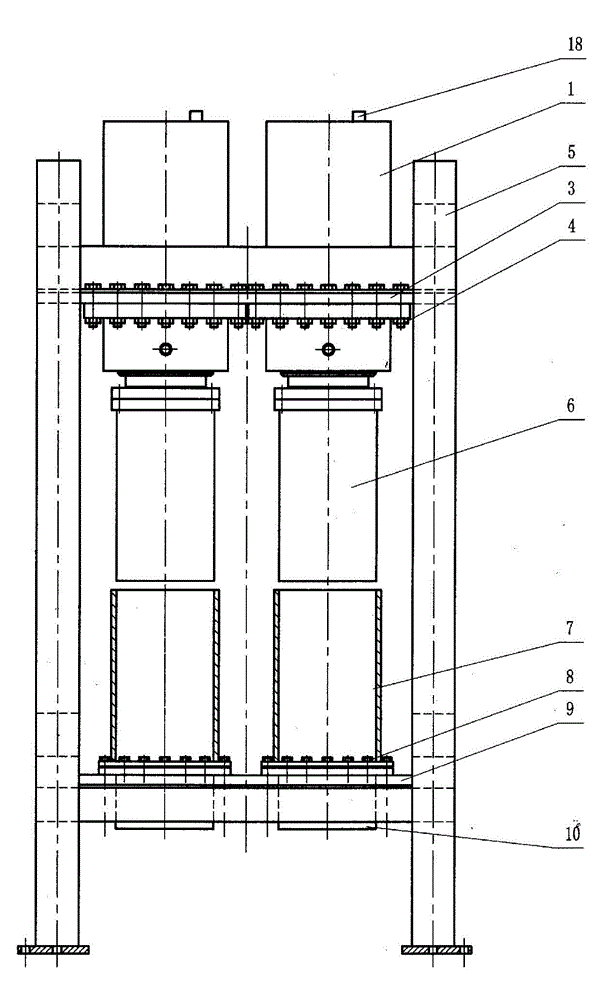

[0017] Depend on Figures 1 to 4 It can be known that the present invention includes one or at least two sets of spiral impeller feeding parts for horizontal feeding, and one or at least two sets of vertical hydroforming vertical multi-cylinder or single-cylinder hydroforming parts corresponding to the screw impeller feeding parts, And the PLC control part that controls the feeding part of the screw impeller and the vertical multi-cylinder or single-cylinder hydroforming part, wherein:

[0018] The spiral impeller feeding part includes a motor 11 fixed on the frame, a cycloidal pinwheel reducer 12 connected to the motor 11, and a shaft coupling 13 and an impeller shaft 26 connected to the cycloidal pinwheel reducer 12, wherein The impeller shaft 26 is arranged in the bearing seat 14 fixed on the frame and in the feeding barrel 17, the screw blade 25 is welded on the impeller shaft 26, the feeding hopper 16 is arranged on the top of the front end of the feeding barrel 17, and t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com