A kind of protective coating for single crystal superalloy and preparation method thereof

A technology of superalloy and protective coating, applied in the direction of metal material coating process, coating, metal layered products, etc., can solve the problems of limited application, easy peeling and failure of coating, thermal-mechanical fatigue, etc., to improve strain tolerance , Solve the problem of poor interface bonding force and improve the effect of interface bonding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

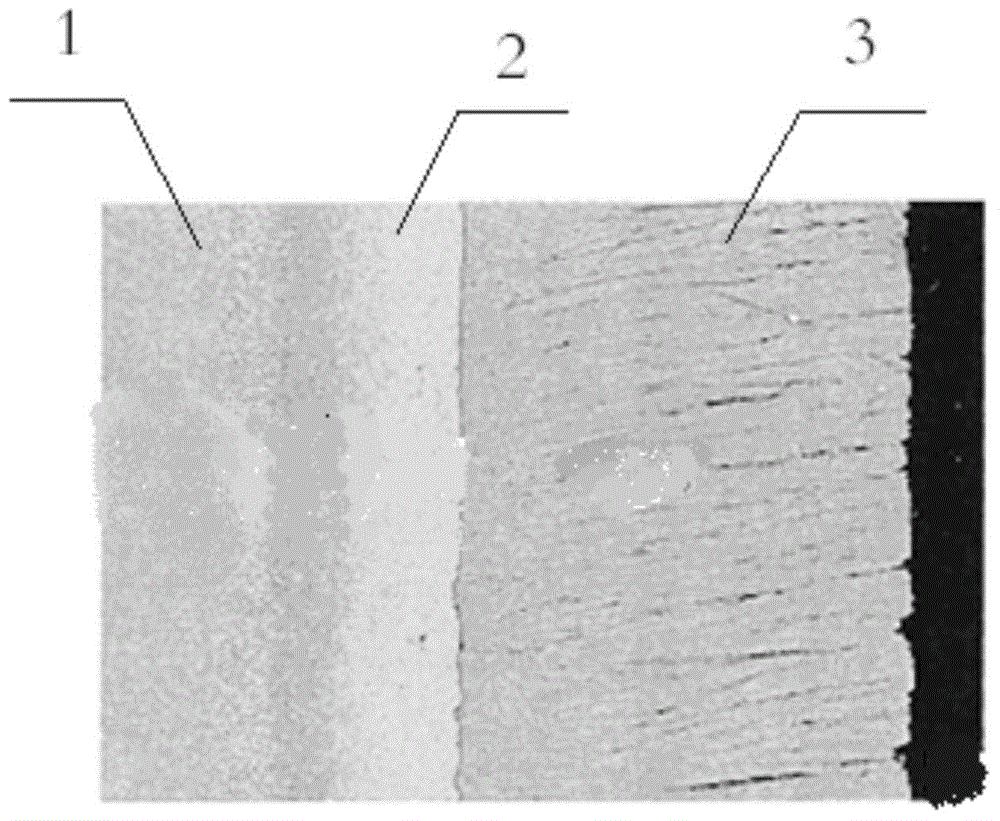

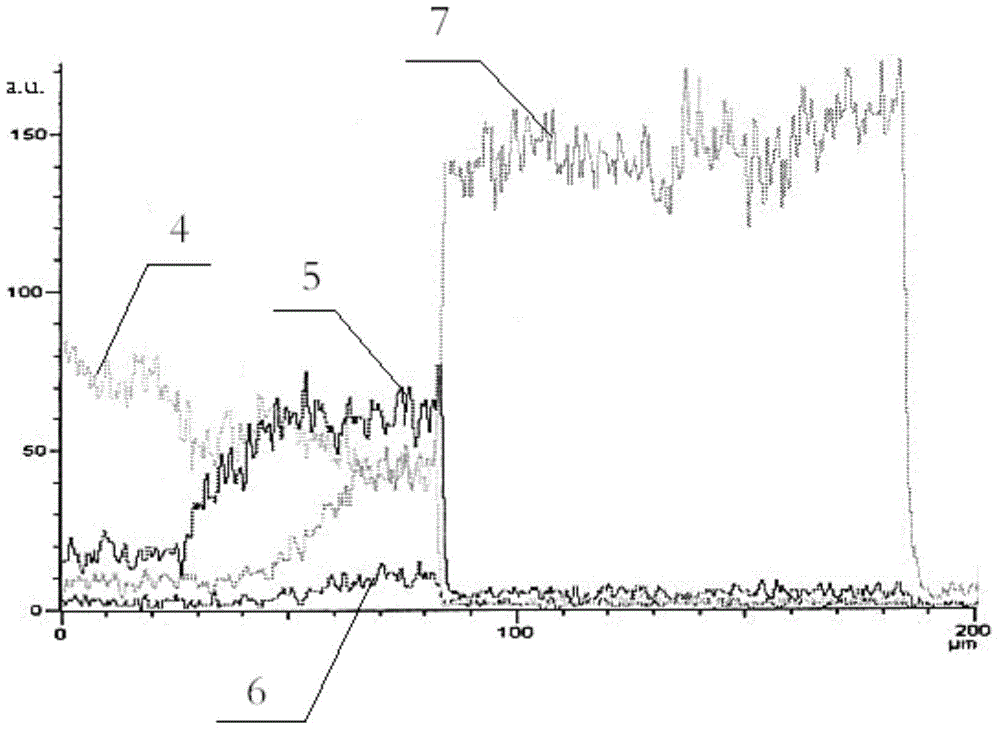

[0032] A protective coating for single crystal superalloy, the protective coating is composed of a PtAl metal bottom layer and a columnar crystal structure YSZ ceramic surface layer. Wherein the PtAl metal bottom layer is a platinum-modified aluminide coating, and the columnar crystal structure YSZ ceramic surface layer is 6-8%Y 2 o 3 Partially stabilized ZrO 2 Columnar crystal structure ceramic surface layer.

[0033] A method for preparing the protective coating for the above-mentioned single crystal superalloy, the preparation method comprises the steps of:

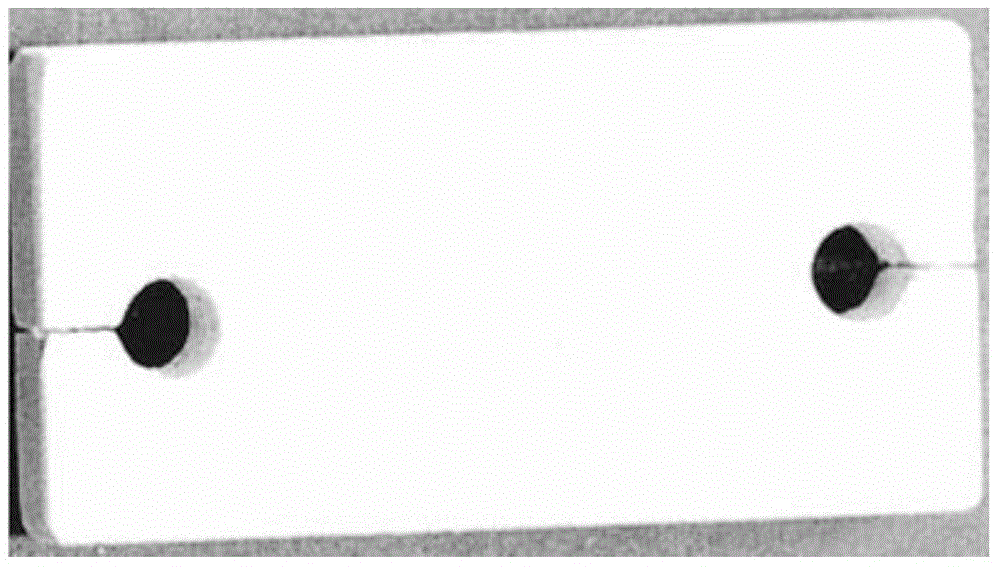

[0034] (1) Preparation steps of the PtAl metal bottom layer

[0035] The preparation steps of the PtAl metal bottom layer are as follows: first, a 10 μm Pt layer is prepared on the surface of the single crystal superalloy blade substrate by electroplating, and then aluminized to the Pt layer by an embedding method, and the thickness of the prepared PtAl metal bottom layer is 50μm;

[0036] (2) Post-treatment steps...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com