Preparation method and application of corrosion and scale inhibitor for ethylene glycol sealed circulating water

A corrosion and scale inhibitor, closed cycle technology, applied in the direction of scale removal and water softening, chemical instruments and methods, complex / solubilizer treatment, etc., to achieve good corrosion and scale inhibition performance, reduce formation, prolong service life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

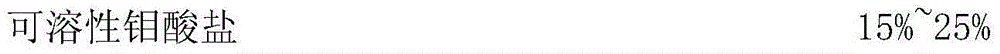

Embodiment 1

[0022] Preparation of component A: Take 16g of sodium hydroxide, add 94g of demineralized water, fully stir until the sodium hydroxide is completely dissolved, then add 30g of acrylic acid-acrylamide-acrylic acid-β-hydroxypropyl ester copolymer, stir evenly, then add soluble molybdenum Acetate 50g, then stir until the solution is uniform, finally add 10g of benzotriazole, mix and stir evenly.

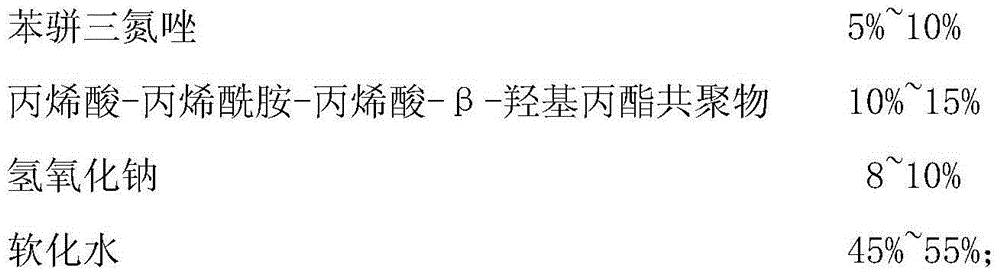

[0023] Preparation of component B: Add 5g of zinc chloride to 48g of demineralized water to fully dissolve, then add 10g of N-lauroyl sarcosine, 7g of sodium gluconate, itaconic acid-acryloyl morpholine-N-acryloyl-N-methyl Propyl phosphonic acid copolymer 30g is uniformly prepared by mixing and stirring.

Embodiment 2

[0025] Preparation of component A: Take 16g of sodium hydroxide, add 94g of demineralized water, fully stir until the sodium hydroxide is completely dissolved, then add 30g of acrylic acid-acrylamide-acrylic acid-β-hydroxypropyl ester copolymer, stir evenly, then add soluble molybdenum Acetate 50g, then stir until the solution is uniform, finally add 10g of benzotriazole, mix and stir evenly.

[0026] Preparation of component B: Add 5g of zinc chloride to 48g of demineralized water to fully dissolve, then add 10g of N-lauroyl sarcosine, 7g of sodium gluconate, itaconic acid-acryloyl morpholine-N-acryloyl-N-methyl Propyl phosphonic acid copolymer 30g is uniformly prepared by mixing and stirring.

Embodiment 3

[0028] Preparation of component A: Take 16g of sodium hydroxide, add 94g of demineralized water, fully stir until the sodium hydroxide is completely dissolved, then add 30g of acrylic acid-acrylamide-acrylic acid-β-hydroxypropyl ester copolymer, stir evenly, then add soluble molybdenum Acetate 50g, then stir until the solution is uniform, finally add 10g of benzotriazole, mix and stir evenly.

[0029] Preparation of component B: Add 5g of zinc chloride to 48g of demineralized water to fully dissolve, then add 10g of N-lauroyl sarcosine, 7g of sodium gluconate, itaconic acid-acryloyl morpholine-N-acryloyl-N-methyl Propyl phosphonic acid copolymer 30g is uniformly prepared by mixing and stirring.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com