Chemi-mechanical pulp wastewater treatment technology and device with coupled membrane separation and evaporation

A treatment process and treatment device technology, applied in the field of chemical-mechanical-slurry wastewater membrane separation coupled with evaporation treatment, can solve the problems of high energy consumption and large processing capacity of the evaporation process, so as to prolong the service life of the membrane, reduce the amount of external drainage, and achieve a large amount of recycling. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0082] The comprehensive waste water of wheat straw straw chemical pulping, the water quality index of waste water is shown in Table 1.

[0083] Table 1 Water quality indicators of wheat straw chemical pulp wastewater

[0084]

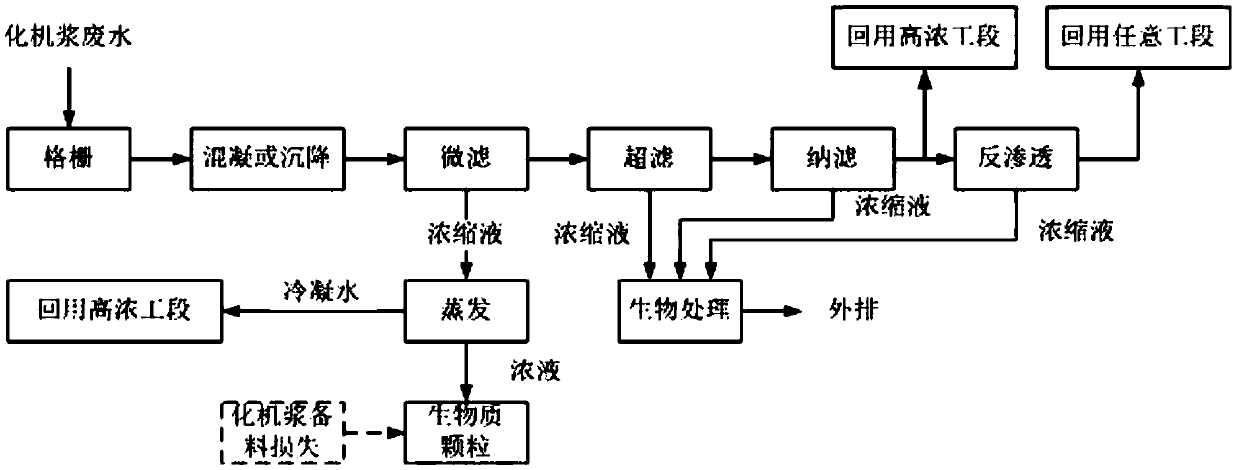

[0085] Processing technology such as figure 1 As shown, after flocculation and sedimentation, part of the suspended matter was removed, and the COD Cr Reduced, the settled wastewater is filtered step by step through microfiltration, ultrafiltration, nanofiltration and reverse osmosis. Microfiltration adopts 500nm ceramic membrane with operating pressure of 0.3MPa, ultrafiltration adopts 50nm ceramic membrane with operating pressure of 0.3MPa, and nanofiltration adopts TFM composite fiber membrane with filtration accuracy of 150MWCO, operating pressure 1.0MPa, reverse osmosis adopts 0.1nm polyamide composite membrane, operating pressure 1.0MPa. After the waste water is filtered by microfiltration, the solid concentration of the concentrated liquid ...

Embodiment 2

[0093] Table 4 shows the water quality indicators of poplar chemical-mechanical pulp comprehensive wastewater.

[0094] Table 4 Water quality indicators of poplar chemical-mechanical pulp wastewater

[0095]

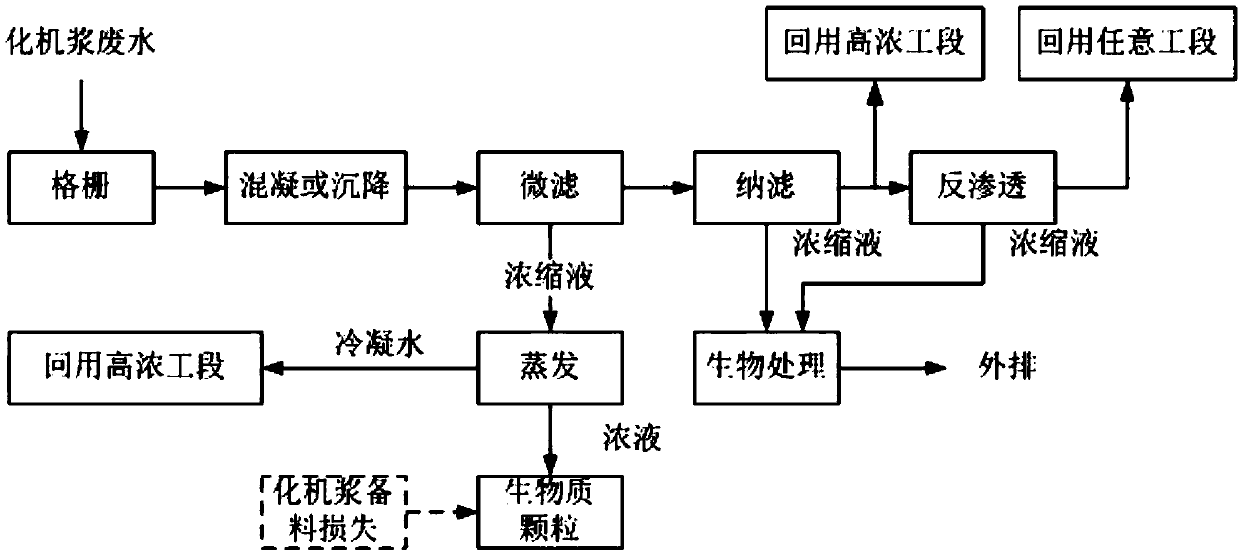

[0096] Processing technology such as figure 2 As shown, after flocculation and sedimentation, part of the suspended matter was removed, and the COD Cr The settled waste water is filtered step by step through microfiltration, nanofiltration and reverse osmosis. The microfiltration adopts 200nm ceramic membrane and the operating pressure is 0.3MPa. The nanofiltration adopts TFM composite fiber membrane with a filtration accuracy of 300MWCO and the operating pressure is 1.5MPa. The reverse osmosis adopts 0.1nm polyamide composite membrane, and the operating pressure is 3.5MPa. After the waste water is filtered by microfiltration, the solid concentration of the concentrated liquid is increased to 2.8%, which is used for evaporation treatment, and evaporated to a solid ...

Embodiment 3

[0104] Table 7 shows the water quality indicators of wheat straw straw chemical pulp comprehensive wastewater.

[0105] Table 7 Water quality indicators of wheat straw chemical pulp wastewater

[0106]

[0107] Processing technology such as figure 1 As shown, after flocculation and sedimentation, part of the suspended matter was removed, and the COD Cr The waste water after sedimentation is sent to the adsorption device for adsorption treatment. The adsorption device is filled with wheat husks removed during the preparation of wheat straw. The flow rate of the adsorption process is 10BV / h. The adsorption water is then subjected to microfiltration, ultrafiltration, nanofiltration, and reverse osmosis. Step by step filtration, microfiltration adopts 500nm ceramic membrane, operating pressure 0.3MPa, ultrafiltration adopts 50nm ceramic membrane, operating pressure 0.4MPa, nanofiltration adopts TFM composite fiber membrane with filtration accuracy of 300MWCO, operating pressur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com