A kind of cyanide-containing high-concentration ammonium sulfite wastewater treatment method

A technology for ammonium sulfite and wastewater treatment, applied in water/sewage treatment, multi-stage water/sewage treatment, degassed water/sewage treatment, etc., can solve the problem of increased alkali consumption, liquid alkali waste, and increased wastewater discharge Quantity and other issues, to achieve the effect of low product cost, sufficient ammonia recovery, and reduced input

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

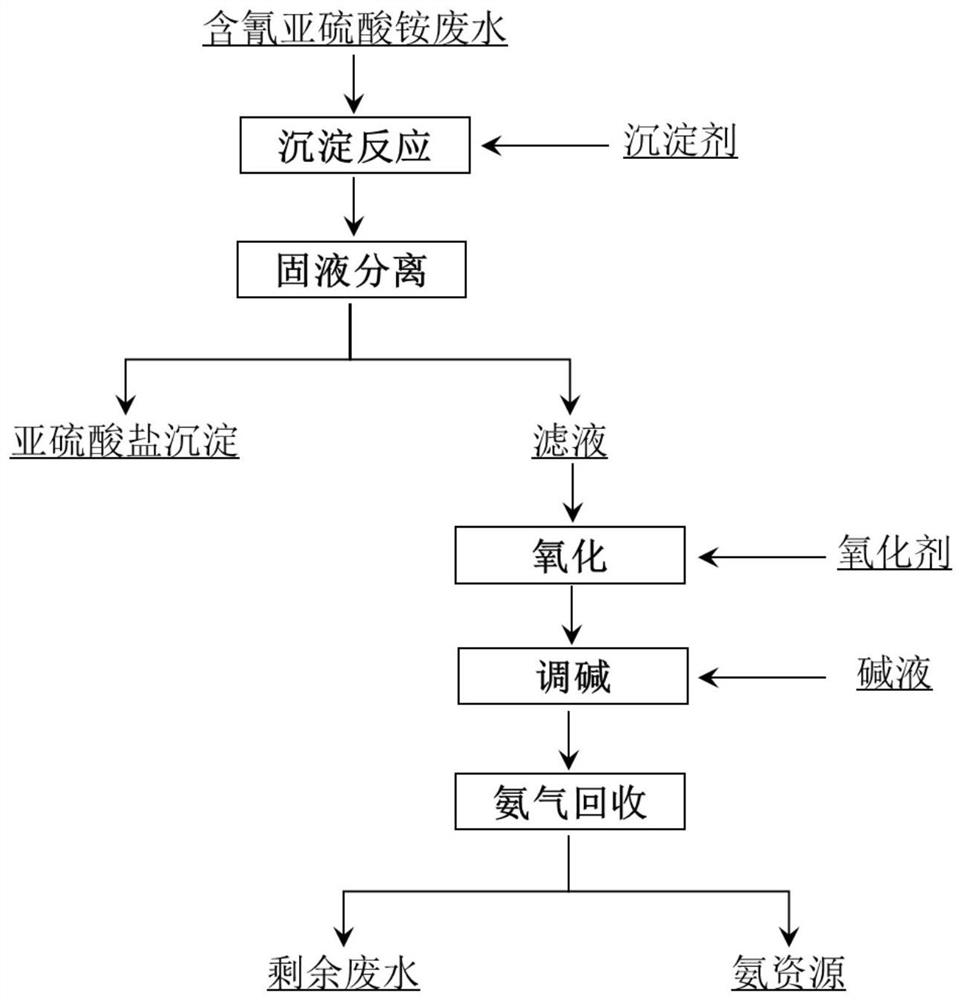

[0087] A kind of cyanide-containing high-concentration ammonium sulfite wastewater treatment method comprises the following steps:

[0088] 1) remove sulfite ion: add sulfite precipitant to waste water, generate sulfite precipitate, separate after reaction is completed, obtain filtrate;

[0089] 2) removing cyanide ions: adding an oxidant to the filtrate, the cyanide ions react with the oxidant to obtain a solution for removing cyanide ions;

[0090] 3) Ammonia gas recovery: add lye to the solution from which cyanide ions have been removed, adjust the solution to alkaline, and recover ammonia gas through the ammonia gas recovery system.

Embodiment 2

[0092] A method for treating cyanogen-containing high-concentration ammonium sulfite wastewater, the method comprising the following steps:

[0093] 1) Remove sulfite ions: add calcium oxide to the wastewater to generate calcium sulfite precipitate, stir for 12 hours, and separate by filtration after the reaction is completed to obtain the filtrate;

[0094] 2) Removing cyanide ions: adding hydrogen peroxide to the filtrate, the cyanide ions react with hydrogen peroxide, the reaction time is 0.5h, and the reaction temperature is 40°C; a solution for removing cyanide ions is obtained;

[0095] 3) Recover ammonia: add sodium hydroxide to the solution from which cyanide ions are removed, adjust the solution to be alkaline, and the pH value is 9-12; recover ammonia through the ammonia recovery system;

[0096] Wherein: the concentration of sulfurous acid in the high-concentration ammonium sulfite wastewater containing cyanide is 0.08mol / L; Step 1) the ratio of the molar weight of ...

Embodiment 3

[0098] Repeat embodiment 2, just the concentration of sulfurous acid in the high-concentration ammonium sulfite wastewater containing cyanide is 0.15mol / L, replace calcium oxide with ferrous sulfate in step 1), adopt suction filtration to separate; Step 1) add ferrous sulfate The ratio of the molar amount of sulfite ion to the molar amount of sulfite ion in wastewater is 1:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com