Method for preparing tetrahydrofuran by using succinic acid fermentation broth

A technology of tetrahydrofuran and succinic acid, applied in the direction of organic chemistry and the like, can solve problems such as reducing product yield, and achieve the effect of reducing cost and simplifying sodium removal process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

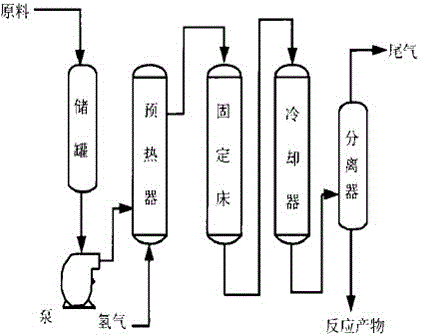

Method used

Image

Examples

Embodiment 1

[0034] The fermentation broth was prepared with a target volume of 2400L. The nutrient base composition of the fermentation broth: 36g of potassium dihydrogen phosphate, 12g of sodium hydrogen phosphate, 1g of magnesium chloride, 1g of calcium chloride, 24kg of yeast extract, 24kg of corn steep liquor, 201.4kg of sodium carbonate, 336kg of glucose (85%), and the rest is water. Actinobacillus succinogenes CGMCC1593 was used as the synthetic strain of succinic acid. After actual sterilization, cooling, and inoculation, the fermentation temperature was 37-38°C, the stirring speed was 60rpm, and the fermentation time was 48 hours. The acid content is 95g / L.

[0035] The above-mentioned fermented liquid is separated from bacteria through a centrifuge, the centrifuge is disc type, the rotating speed is 4000rpm, the obtained clear and transparent liquid is 2300L, and the content of succinic acid is 90g / L.

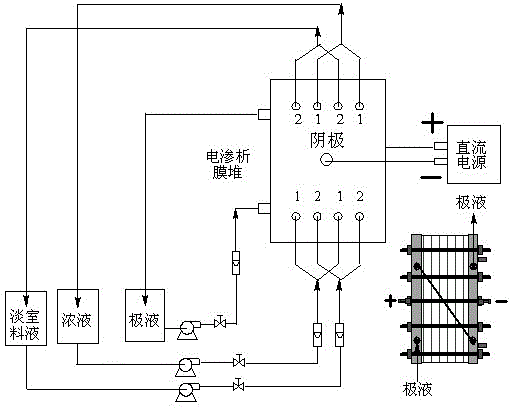

[0036]The clarified fermentation broth is placed in a bipolar membra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com