Method for preparing sodium polyacrylate dispersant

A technology of sodium polyacrylate and acrylic acid, applied in the field of polymers, can solve the problems of high cost of acrylic acid aqueous solution treatment, and achieve the effects of avoiding uneven molecular weight and low production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

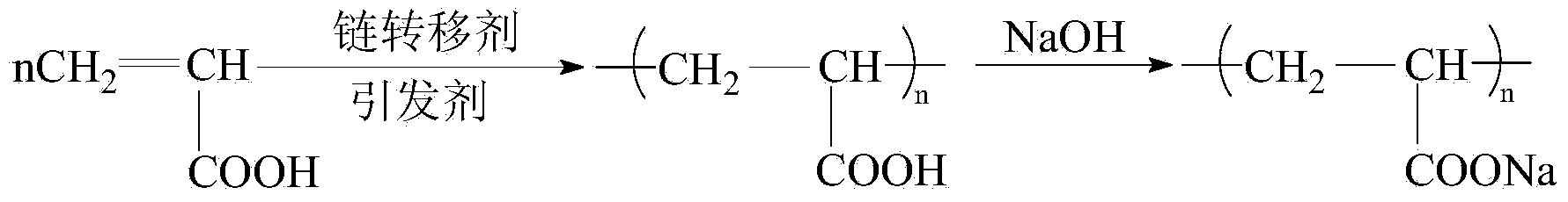

[0019] The embodiment of the present invention discloses a preparation method of sodium polyacrylate dispersant, comprising the following steps:

[0020] mixing the first acrylic acid waste liquid and the chain transfer agent, heating, then adding the initiator and the second acrylic acid waste liquid dropwise, and reacting to obtain a reaction product;

[0021] The pH of the reaction product is adjusted with solid sodium hydroxide to obtain a sodium polyacrylate dispersant.

[0022] In the process of preparing the sodium polyacrylate dispersant in the present invention, firstly, the first acrylic acid waste liquid and the chain transfer agent are mixed and then heated, so that the first acrylic acid waste liquid and the chain transfer agent are evenly mixed. The concentration of the first acrylic acid waste liquid is preferably 3wt%-9wt%, and the addition amount of the first acrylic acid waste liquid is 10wt%-20wt of the total amount of the first acrylic acid waste liquid and...

Embodiment 1

[0032] Add 100ml of acrylic acid wastewater with a content of 5wt% into a 1500ml three-necked flask, add 5g of sodium methacrylate, and heat to 70°C. Start stirring, slowly add 900ml of 5wt% acrylic acid wastewater and 50ml of 5wt% ammonium persulfate dropwise; the dropping time is controlled at 1h, and the temperature is controlled for 0.5h after the dropping, and the pH value is adjusted to 7-9 with solid sodium hydroxide , to obtain the reaction solution. The molecular weight of the reaction solution was measured, and the viscosity-average molecular weight distribution was 1500-3000. The reaction solution was concentrated by evaporation to 200ml, and the measured solid content was 42%, and the conversion rate of acrylic acid was 98%.

Embodiment 2

[0034] Add 200ml of acrylic acid wastewater with a content of 5wt% into a 1500ml three-necked flask, add 5g of sodium methacrylate, and heat to 80°C. Start stirring, and slowly add 800ml of 5wt% acrylic acid wastewater and 50ml of 5wt% ammonium persulfate dropwise; the dropping time is controlled at 1h, and the temperature is controlled for 0.5h after the dropping, and the pH value is adjusted to 7-9 with solid sodium hydroxide , to obtain the reaction solution. The molecular weight of the reaction solution was measured, and the viscosity-average molecular weight distribution was 1500-3000. The reaction liquid was concentrated by evaporation to 200ml, the measured solid content was 42%, and the conversion rate of acrylic acid was 97.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com