Brand discoloration wet-process polyurethane resin with good hydrolysis resistance

A technology of wet-process polyurethane and polyurethane resin, which is applied in the field of imprinted color-changing wet-process polyurethane resin and its preparation, which can solve the problems of insignificant pressure change effect, poor surface flatness, and poor hydrolysis resistance, and achieve strong three-dimensional effect and good hydrolysis resistance. Good aging resistance and surface smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

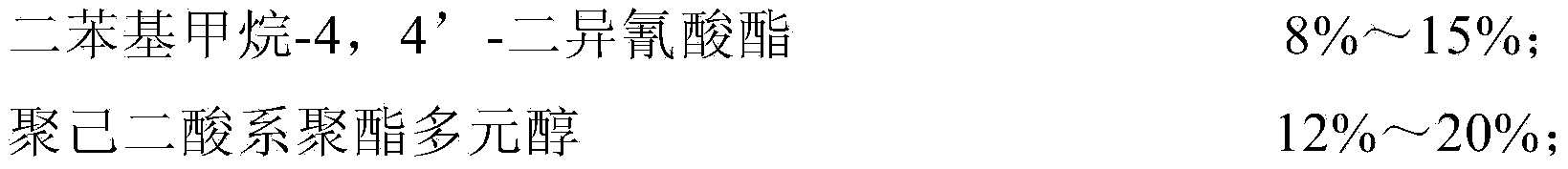

[0023] 1. Formula

[0024]

[0025] 2. Preparation method

[0026] In reactor, drop into polyethylene adipate-butylene glycol (number average molecular weight 1000g / mol) 112.5kg, polyethylene adipate glycol-butylene glycol (number average molecular weight 3000g / mol) mol) 37.5kg, 1,4-butanediol 25.48kg and N,N-dimethylformamide (DMF) 181kg, stir well and put in diphenylmethane-4,4'-diisocyanate (MDI) 95.9kg , the reaction temperature is controlled at 75-85°C, after 1-3 hours of reaction, when the viscosity of the reaction liquid reaches 180-200Pa·s / 50°C, put 7.5kg of hydroxyl fluorosilicone oil (number-average molecular weight 10000g / mol) into the reaction kettle, B Diol 1.95kg, MDI8kg and 570kgDMF, the reaction temperature is controlled at 75-85°C, after 1-2 hours of reaction, add the remaining amount of MDI, until the final viscosity is 25°C, 150-250Pa·s, add polyoxypropylene triol 9.88 kg, stirred evenly, and ended the reaction.

Embodiment 2

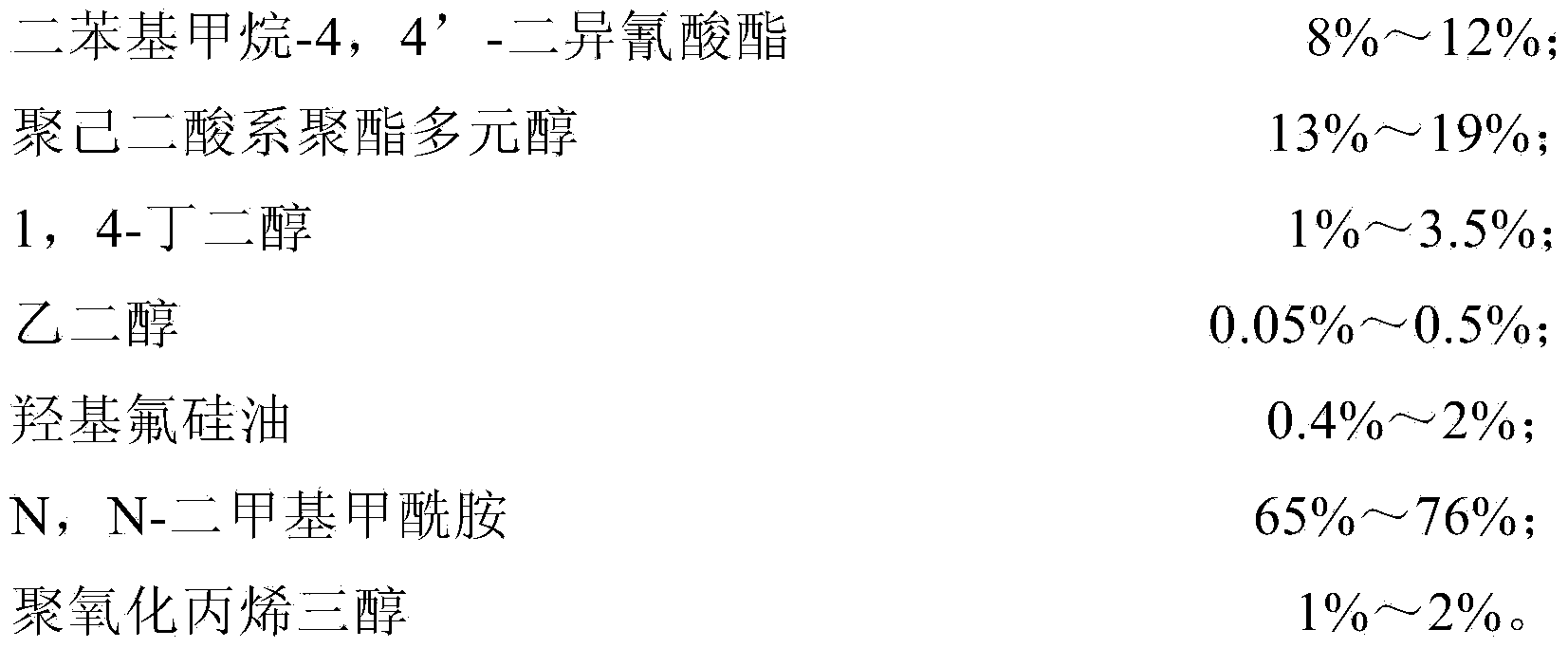

[0028] 1. Formula

[0029]

[0030]

[0031] 2. Preparation method

[0032] In reactor, drop into polyethylene adipate-butylene glycol ester diol (number average molecular weight 1000g / mol) 150kg, 1,4-butanediol 17.17kg and N, N-dimethylformamide (DMF ) 248kg, after stirring evenly, 80.9kg of diphenylmethane-4,4'-diisocyanate (MDI) was added, the reaction temperature was controlled at 75-85°C, and after 1-3 hours of reaction, the viscosity of the reaction liquid reached 150-180Pa·s / At 50°C, put 10kg of hydroxyfluorosilicone oil (number average molecular weight 16000g / mol), 1.97kg of ethylene glycol, 7kg of MDI and 503kg of DMF into the reaction kettle, and control the reaction temperature at 75-85°C. After 1-2 hours of reaction, add the remaining Amount of MDI, until the final viscosity is 150-250 Pa·s at 25°C, add 18.17 kg of polyoxypropylene triol, stir evenly, and end the reaction.

Embodiment 3

[0034] 1. Formula

[0035]

[0036] 2. Preparation method

[0037] Put 155kg of polyethylene adipate-butylene glycol ester diol (number average molecular weight 2000g / mol), 26kg of 1,4-butanediol and N,N-dimethylformamide (DMF) into the reactor 142kg, after stirring evenly, put in 82.66kg of diphenylmethane-4,4'-diisocyanate (MDI), the reaction temperature is controlled at 75-85°C, after 1-3 hours of reaction, the viscosity of the reaction liquid reaches 220-250Pa·s / 50 At ℃, put 15.5kg of hydroxyfluorosilicone oil (number average molecular weight 16000g / mol), 1.79kg of ethylene glycol, 11kg of MDI and 601.5kg of DMF into the reaction kettle, and control the reaction temperature at 75~85℃. For the remaining amount of MDI, until the final viscosity is 25°C, 150-250 Pa·s, add 19.83 kg of polyoxypropylene triol, stir evenly, and end the reaction.

PUM

| Property | Measurement | Unit |

|---|---|---|

| number average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com