Water-soluble alkyd resin and preparation method thereof

An alkyd resin, water-soluble technology, applied in the field of coatings, can solve the problems of high surface tension, poor weather resistance, shrinkage cavities, etc., and achieve the effect of improving weather resistance

Active Publication Date: 2014-02-05

山东乐化漆业股份有限公司

View PDF3 Cites 3 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, the problems of water-soluble coatings represented by drying oils are mainly manifested in: the paint film is hard and brittle, and the weather resistance is poor; the surface tension is large, resulting in shrinkage; in weak alkaline aqueous solution, the ester bond will be hydrolyzed and affect the coating. Storage shortens service life

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

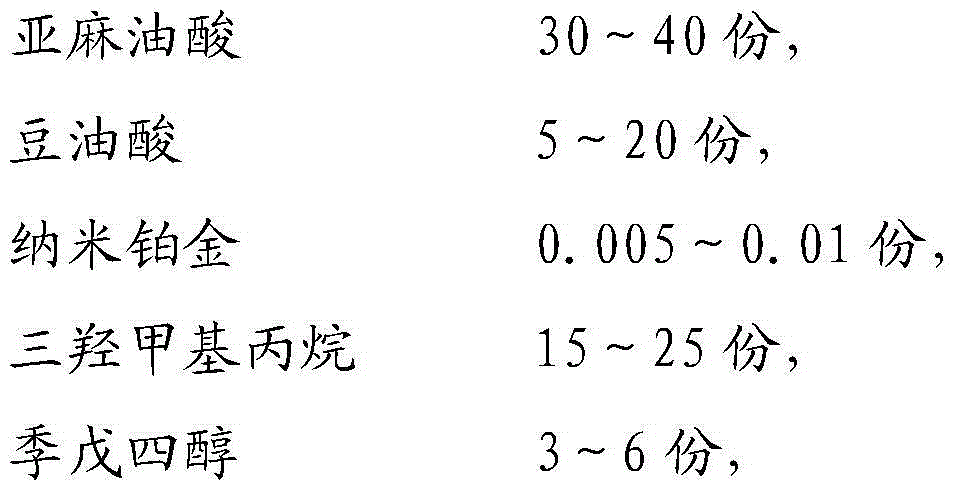

[0029] A water-soluble alkyd resin, comprising the following raw material components:

[0030]

[0031]

Embodiment 2

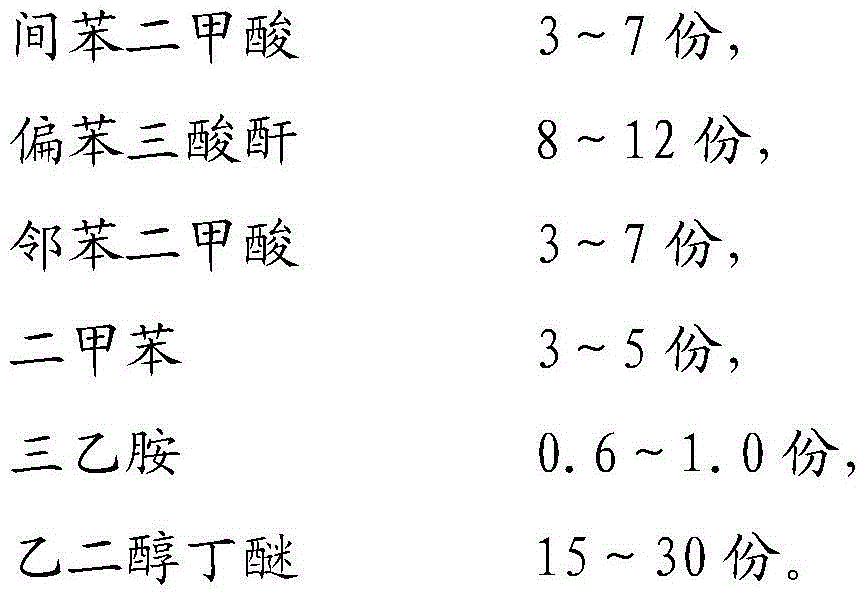

[0033] A water-soluble alkyd resin, comprising the following raw material components:

[0034]

Embodiment 3

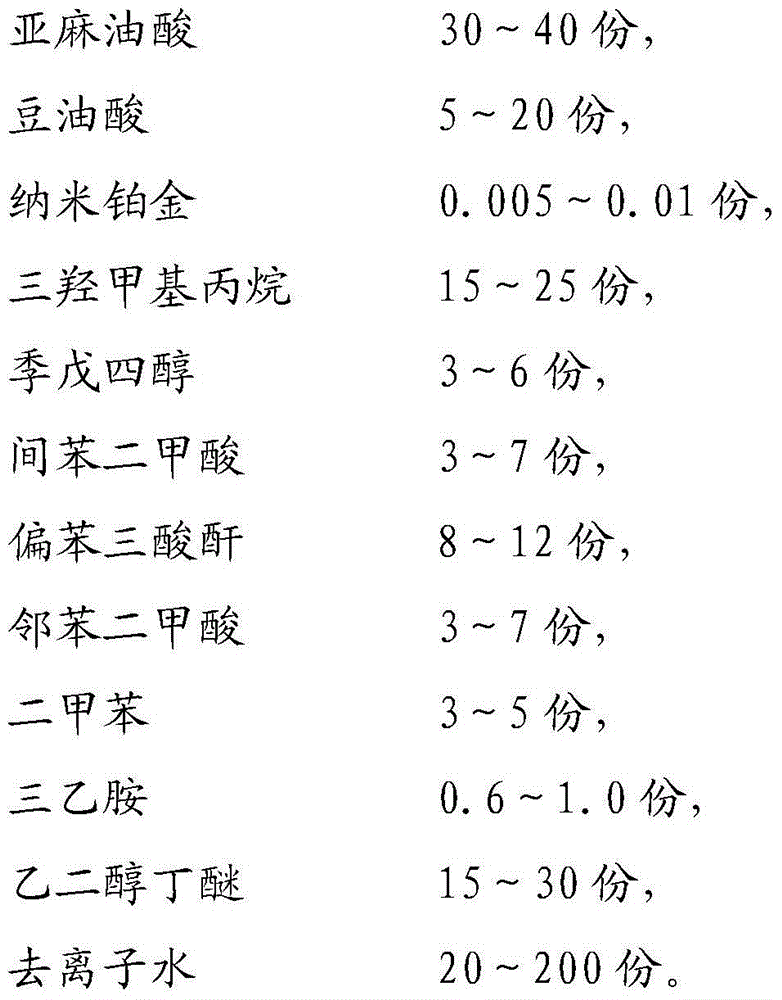

[0036] A water-soluble alkyd resin, comprising the following raw material components:

[0037]

[0038]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses a water-soluble alkyd resin and a preparation method thereof. The water-soluble alkyd resin comprises the following active ingredients in parts by weight: 30-40 parts of linoleic acid, 5-20 parts of soya oil acid, 0.005-0.001 part of nano platinum, 15-25 parts of trimethylol propane, 3-6 parts of pentaerythritol, 3-7 parts of isophthalic acid, 8-12 parts of trimellitic anhydride, 3-7 parts of pathalic acid, 3-5 parts of xylene, 0.6-1.0 part of trithylamine, and 15-30 parts of ethylene glycol monobutyl ether. The preparation method comprises the steps of heating and melting linoleic acid, trimethylol propane, xylene, pentaerythritol and pathalic acid, adding nano platinum and soya oil acid at 230-250 DEG C, preserving heat and reacting at 190-210DEG C, cooling to 180 DEG C below, adding trimellitic anhydride, preserving heat and reacting at 160-170DEG C, preparing the solution by taking ethylene glycol monobutyl ether as a solvent, and neutralizing to be neutral with trithylamine to obtain the water-soluble alkyd resin.

Description

technical field [0001] The invention relates to the technical field of coatings, in particular to a water-soluble alkyd resin. Background technique [0002] The biggest advantage of water-soluble paint is that water replaces organic solvents, so compared with traditional solvents, it has the characteristics of low cost, convenient construction, and no environmental pollution. Among them, water-soluble alkyd resins are the most used type, especially alkyd resins represented by dry oils such as linseed oil have been industrialized. However, the problems of water-soluble coatings represented by drying oils are mainly manifested in: the paint film is hard and brittle, and the weather resistance is poor; the surface tension is large, resulting in shrinkage; in weak alkaline aqueous solution, the ester bond will be hydrolyzed and affect the coating. Storage shortens service life. [0003] Therefore, how to produce a water-soluble alkyd resin with excellent dryness and salt spray...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C08G63/49C08G63/82

Inventor 沈孝忠张生军曹学强

Owner 山东乐化漆业股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com