Black rice vinegar and preparation method thereof

A technology for black rice vinegar and black rice, which is applied to the preparation of vinegar, biochemical equipment and methods, methods based on microorganisms, etc. The effect of easy control of conditions, rich vinegar aroma and high health value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

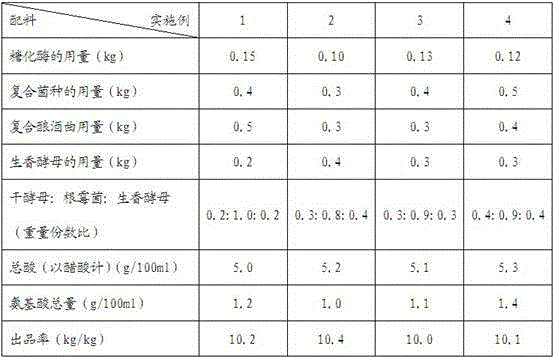

Embodiment 1-4

[0043] Embodiment 1-4 is respectively a kind of batching scheme of black rice vinegar, and the preparation of vinegar is based on existing conventional vinegar-making method, and the total consumption of black rice is 100kg in each embodiment, and compound bacterial classification is by Aspergillus niger , Aspergillus oryzae and Rhizopus compound, their ratio of parts by weight is 1:1:1, and the composition of other ingredients is shown in Table 1:

[0044] Table 1 Ingredients of black rice vinegar

[0045]

[0046] In the table, the output rate of black rice vinegar is 1kg black rice raw material production total acid standard is the output of 3.5 g / 100ml vinegar, the calculation formula of the output rate of black rice vinegar is as follows:

[0047]

[0048] P—measured total acid content of black rice vinegar, g / 100ml;

[0049] m—actual output of vinegar, kg;

[0050] m 1 - the total weight of black rice raw materials, kg;

[0051] 3.5 is the total acid content of...

Embodiment 5-8

[0053] The preparation method of embodiment 5-8 black rice vinegar

[0054] Examples 5-8 are respectively a method for preparing black rice vinegar, based on the existing ingredients of black rice vinegar, respectively, according to the following steps (see Table 2 for specific control parameters):

[0055] ⑴ crushing

[0056] Divide the black rice into two parts A1 and A2 with a weight ratio of 2:1, grind A1 and pass through a 30-mesh sieve to obtain black rice flour A;

[0057] ⑵ Blending

[0058] Add 4-5 times the volume of water and amylase to A to obtain B after dissolving;

[0059] (3) liquefaction

[0060] Adjust the temperature of B to 85-92°C, the pH to 6.5-7.0, and keep it warm for 15-25min to obtain C;

[0061] ⑷Saccharification

[0062] Add glucoamylase to C, and the koji material obtained from A2 after making koji with compound strains, and saccharify at 60-65°C for 30-45min to obtain D;

[0063] Among them, the koji material is prepared by culturing A2 at 3...

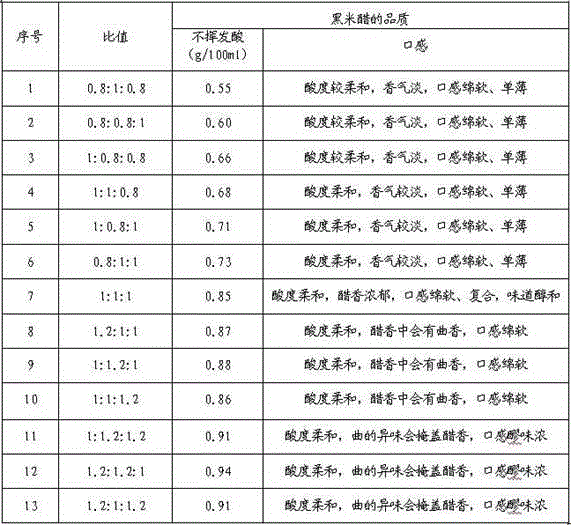

Embodiment 9-13

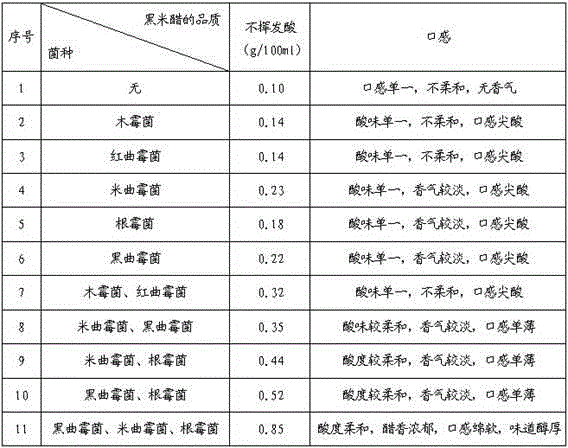

[0077] Embodiment 9-13 Black rice vinegar and its preparation method

[0078] Embodiment 9-13 is a kind of black rice vinegar and preparation method thereof respectively, and the total consumption of black rice is 100kg in each embodiment, and composite bacterial classification is formed by aspergillus niger, aspergillus oryzae and rhizopus composite, and their weight The ratio of parts is 1:1:1, and other ingredients and control parameters in the preparation process are shown in Table 3:

[0079] Table 3 The ingredients of black rice vinegar and the control parameters in the preparation process

[0080]

[0081] The preparation method of the black rice vinegar involved in embodiment 9-13 is carried out according to the following steps respectively:

[0082] ⑴ crushing

[0083] Divide the black rice into two parts A1 and A2 with a weight ratio of 2:1, grind A1 and pass through a 30-mesh sieve to obtain black rice flour A;

[0084] ⑵ Blending

[0085] Add 4-5 times the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com