A kind of strawberry mulberry compound rice vinegar and preparation method thereof

A compound rice and mulberry technology, which is applied in the preparation of vinegar, medical formula, drug combination, etc., can solve the problems of insufficient nutrients, light taste, low dry extract, etc., to improve health care function, soft and mellow taste, dry extract Enhanced effects of food and nutrients

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

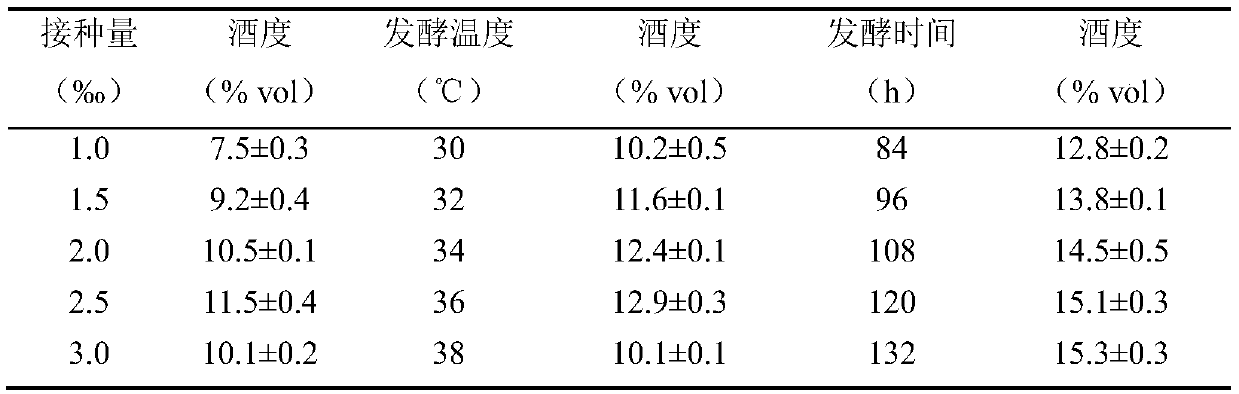

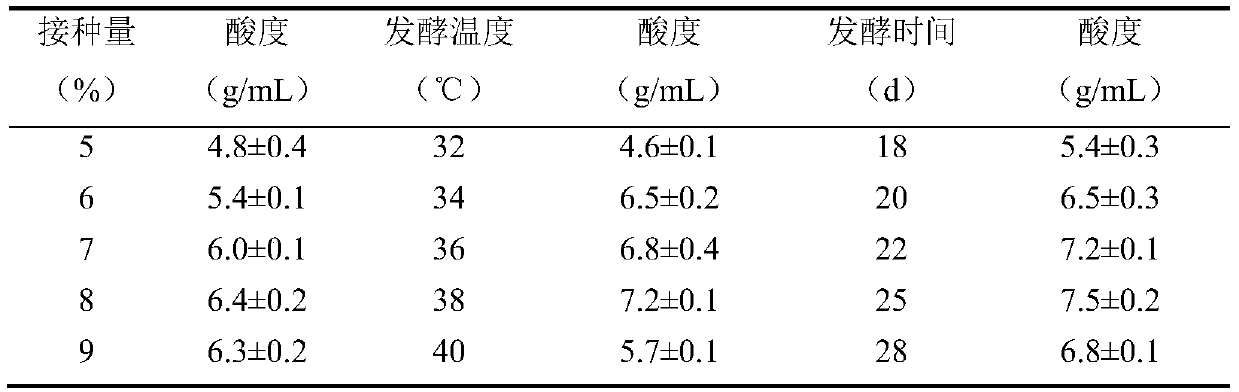

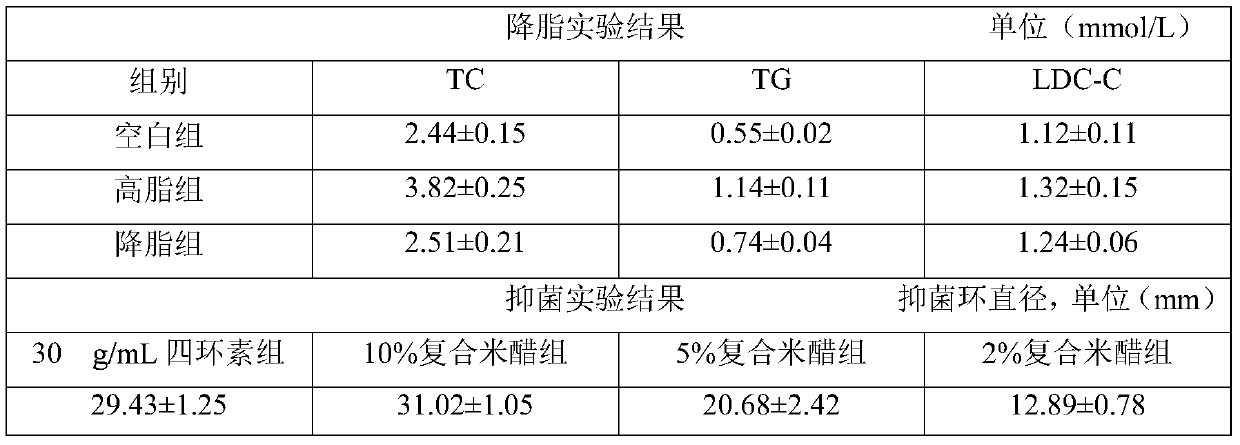

[0043] The nature of the present invention and main parameter are described below by concrete test:

[0044] Select strawberry and mulberry fruits that are disease-free, complete in shape, and eight-mature with a weight ratio of 3:1, soak in salt water for 8 minutes, and then rinse them twice with water; cut the fruit into small pieces, add water twice the weight of the fruit and 1.5 times the weight of the fruit. % iso-Vc sodium and then mix and squeeze the juice, adjust the pH value of the juice with sodium bicarbonate to be 6.0, add compound enzyme (by pectinase and cellulase in 2:1 weight ratio) by the amount of 0.5% of the fruit mass ), the enzymolysis temperature is 55°C, and the enzymolysis time is 60min. After inactivating the enzyme in a boiling water bath for 1min, filter with 300 mesh gauze, steam sterilize at 121°C for 15min, and cool to room temperature to obtain mixed fruit juice of strawberry and mulberry for later use.

[0045]Soak the rice in clear water for 2...

Embodiment 2

[0067] The preparation method of strawberry mulberry compound rice vinegar is as follows:

[0068] (1) Preparation of Strawberry and Mulberry Mixed Juice

[0069] Select strawberry and mulberry fruits that are disease-free, complete in shape, and eight-mature with a weight ratio of 3:1, soak in salt water for 8 minutes, and then rinse them twice with water; cut the fruit into small pieces, add water twice the weight of the fruit and 1.5 times the weight of the fruit. % iso-Vc sodium and then mix and squeeze the juice, adjust the pH value of the juice with sodium bicarbonate to be 6.0, add compound enzyme (by pectinase and cellulase in 2:1 weight ratio) by the amount of 0.5% of the fruit mass ), the enzymolysis temperature is 55°C, and the enzymolysis time is 60min. After inactivating the enzyme in a boiling water bath for 1min, filter with 300 mesh gauze, steam sterilize at 121°C for 15min, and cool to room temperature to obtain mixed fruit juice of strawberry and mulberry for...

Embodiment 3

[0089] The preparation method of strawberry mulberry compound rice vinegar is as follows:

[0090] (1) Preparation of Strawberry and Mulberry Mixed Juice

[0091] Select strawberry and mulberry fruits that are disease-free, complete in shape, and eight-mature with a weight ratio of 3:1, soak in salt water for 5 minutes, and then rinse with water twice; cut the fruit into small pieces, add water that is 3 times the weight of the fruit and 1.5 times the weight of the fruit. % iso-Vc sodium and then mix and squeeze the juice, adjust the pH value of the juice with sodium bicarbonate to be 6.2, add compound enzyme in the amount of 0.6% of the fruit mass (by pectinase and cellulase in a 2:1 weight ratio ), the enzymolysis temperature is 60°C, and the enzymolysis time is 40min. After inactivating the enzyme in a boiling water bath for 1min, filter with 300-mesh gauze, steam sterilize at 121°C for 15min, and cool to room temperature to obtain mixed fruit juice of strawberries and mulb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bronsted acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com