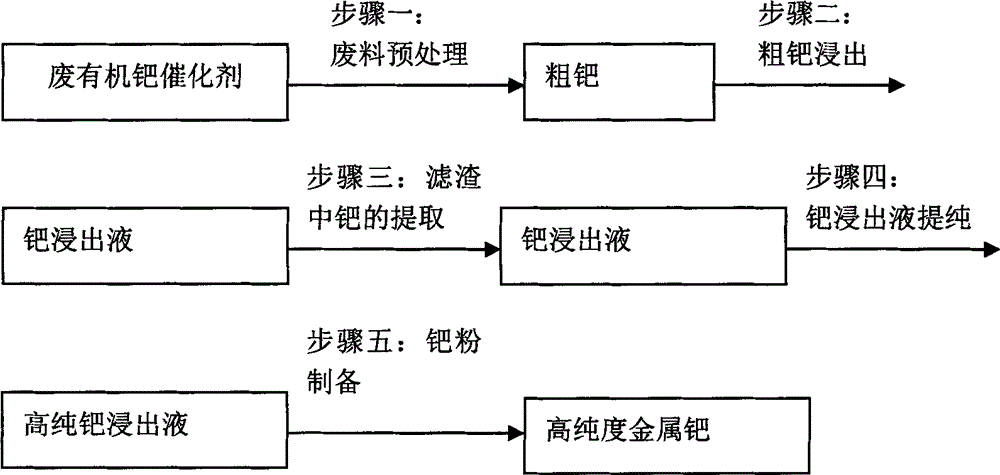

Method for recovering high-purity metal palladium from organic waste palladium contained catalyst

A high-purity, metal palladium technology, which is applied in the field of chemical technology and the recovery of high-purity metal palladium, can solve the problems of high requirements for recycled containers, low palladium recovery rate, cumbersome steps, etc., to save time and improve environmental protection indicators , the effect of simple steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

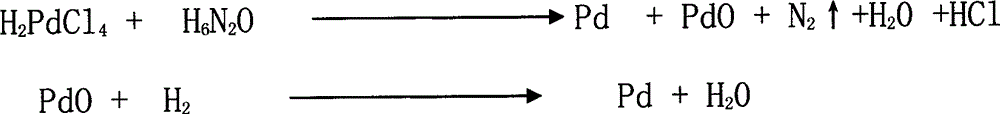

[0022] Get 100 kilograms of viscous solid waste organic palladium catalyst, palladium content 0.08%, put into oxygen-enriched incinerator, the volume flow rate of the air of oxygen-enriched incineration is 4 cubic meters per minute, and incineration process speed carries out incineration treatment with 50 kg / hour , incineration temperature 600 ℃, incineration for 2 hours to get 1.5 kg of crude palladium. Add hydrochloric acid and hydrogen peroxide to organic waste palladium (solid-to-liquid volume ratio is 1:5), wherein the weight ratio of hydrochloric acid and hydrogen peroxide is 9:1, react at 90°C for 5 hours, filter, and add reducing agent hydrazine hydrate to the filter residue to fully After the reaction, add hydrochloric acid and hydrogen peroxide for the second leaching. At this time, the weight ratio of the filter residue to the mixed solution is 1:3.5, and the reaction time is 3 hours at a temperature of 75°C. The two leached liquids were mixed to remove the acid, an...

Embodiment 2

[0024] Get 100 kilograms of viscous solid waste organic palladium catalyst, palladium content 0.08%, put into oxygen-enriched incinerator, the volume flow rate of the air of oxygen-enriched incineration is 6 cubic meters per minute, and incineration treatment speed carries out incineration treatment with 50 kilograms / hour , incineration temperature 650 ℃, incineration for 2 hours to get 1.49 kg of crude palladium. Add the mixed solution of hydrochloric acid, hydrogen peroxide and sodium hypochlorite into organic waste palladium (solid-liquid volume ratio is 1:7), wherein the weight ratio of hydrochloric acid and the mixed solution is 10:1, and in the mixed solution composed of hydrogen peroxide and sodium hypochlorite, two The weight ratio of the former is 4:1, react at 90°C for 5 hours, filter, and then add the mixed solution of hydrochloric acid, hydrogen peroxide and sodium hypochlorite for the second leaching after the filter residue is fully reacted with the reducing agent...

Embodiment 3

[0026] Get 100 kilograms of viscous solid waste organic palladium catalyst, palladium content 0.08%, put into oxygen-enriched incinerator, the volume flow rate of the air of oxygen-enriched incineration is 8 cubic meters per minute, incineration treatment speed carries out incineration treatment with 50 kilograms / hour , incineration temperature 750 ℃, incineration for 3 hours to get 1.51 kg of crude palladium. Add the mixed solution of hydrochloric acid and nitric acid and hydrogen peroxide to the organic waste palladium (solid-liquid volume ratio is 1:7), the mixed solution of hydrochloric acid and nitric acid, the weight ratio of the two is 7:1, and react at 90°C After 5 hours, filter, the filter residue is fully reacted with reducing agent hydrazine hydrate, and then the mixed solution of hydrochloric acid, nitric acid and hydrogen peroxide is added for the second leaching. At this time, the weight ratio of the filter residue and the mixed solution is 1:5. Reaction time 5 h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com