Smelting method for manufacturing large-sized titanium-aluminum alloy ingot

A titanium-aluminum alloy, large-size technology, applied in the smelting field of preparing titanium-aluminum alloy ingots, can solve the problems of small size of smelted ingots, composition segregation, uncontrollable machining, etc., and achieve the effect of complete appearance and uniform structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

[0021] Specific Embodiment 1: This embodiment is a smelting method for preparing a large-size titanium-aluminum alloy ingot, which is specifically completed according to the following steps:

[0022] 1. Preparation of consumable electrodes:

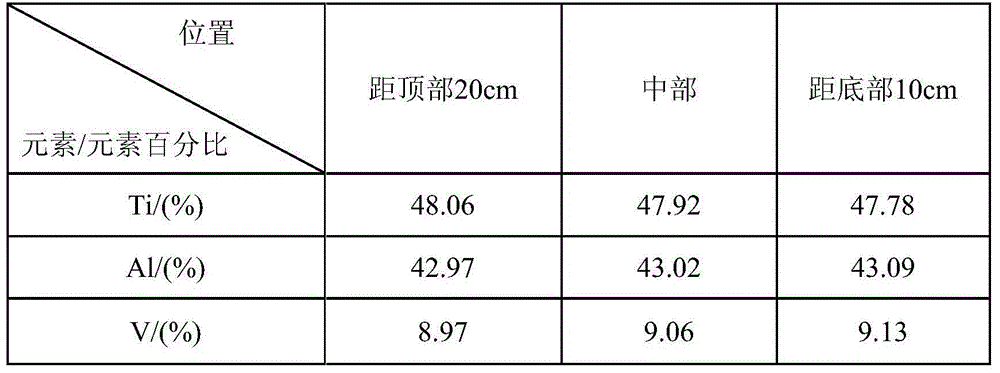

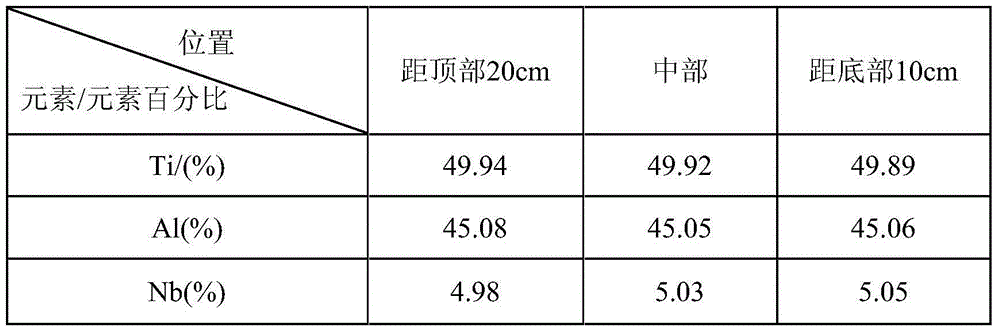

[0023] ① According to the nominal chemical composition Ti-xAl-yM, weigh grade 0 sponge titanium with a material particle size of 12.5 mm to 25.4 mm, aluminum beans with a particle diameter of 2 mm to 10 mm, and intermediate alloy particles with a particle diameter of 0.25 mm to 10 mm; In the Ti-xAl-yM, 43≤x≤45, 5≤y≤9, M is V or Nb; the intermediate alloy particles are aluminum-vanadium alloys with a mass fraction of vanadium of 58% or a mass fraction of niobium of 50% % aluminum-niobium alloy;

[0024] ②Mix the grade 0 sponge titanium, aluminum beans and intermediate alloy particles weighed in step 1 ①, put the mixed pellets into the pressing mold, and press the oil to make the density 2.8g / cm 3 ~3.5g / cm 3 electrode block;

[0025] ③U...

specific Embodiment approach 2

[0034] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the oil pressing described in step 1.2 has a density of 2.9g / cm 3 ~3.4g / cm 3 electrode block. Other steps are the same as in the first embodiment.

specific Embodiment approach 3

[0035] Specific embodiment 3: The difference between this embodiment and specific embodiment 1 or 2 is that in step 2, the melting voltage of the electrode to be melted obtained in step ③ is 27V-35V, and the melting current density is 45A / cm 2 ~65A / cm 2 The smelting is carried out under the condition that the smelting vacuum degree is 0.4Pa-2.5Pa to obtain a primary ingot. Other steps are the same as those in Embodiment 1 or 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com