Cotton polyester interwoven spandex core-spun elastic fabric

A spandex core-spun fabric technology, applied in fabrics, fabric surface trimming, heating/cooling fabrics, etc., can solve problems affecting aesthetics and practicability, high energy consumption in the production process, unstable dimensions, etc., to save steam and energy, saving water and heat energy, and the effect of superior clothing performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

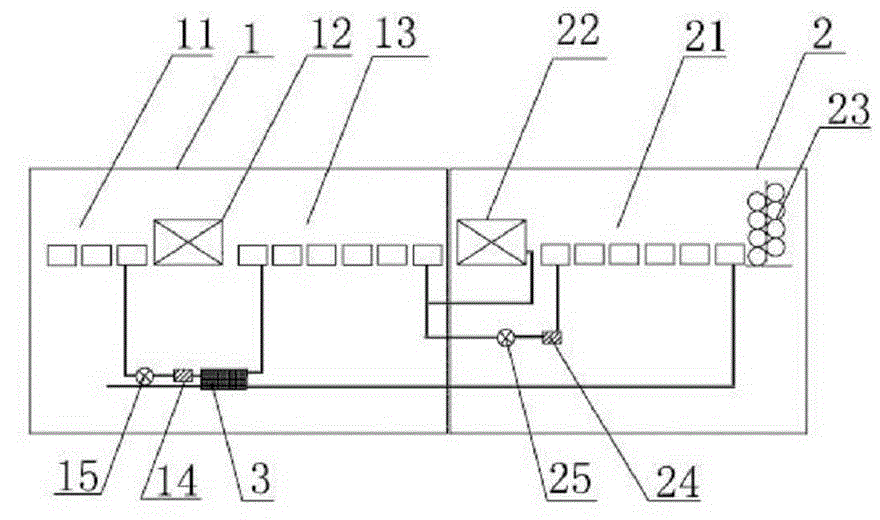

Image

Examples

Embodiment 1

[0036] Cotton-polyester interwoven spandex core-spun elastic fabric, including cotton, polyester and spandex, has 16 counts of cotton in the warp direction, 150D low-elastic network yarn and 70D spandex covered yarn in the weft direction, and its dyeing process includes steps in turn: turning the cloth, returning Pulping, singeing on one side, oxygen bleaching, setting, mercerizing, pad dyeing, dyeing and double dyeing of the same color, finishing.

[0037] The front and back of the fabric are required to be consistent, the seam head is straight, and it is required to be flat, straight, neat, and firm. The stitch density is 42 stitches / 15cm, and the two sides are densely tightened to 3 stitches / cm, so as to prevent wrinkles, weft skew, and curls during printing and dyeing. side.

[0038] The single-side singeing process is specifically gas singeing, singeing twice on the front of the two burners, and the speed is 80-85m / min.

[0039] The combined desizing and bleaching produc...

Embodiment 2

[0049] Cotton-polyester interwoven spandex core-spun elastic fabric, including cotton, polyester and spandex, has 16 counts of cotton in the warp direction, 150D low-elastic network yarn and 70D spandex covered yarn in the weft direction, and its dyeing process includes steps in turn: turning the cloth, returning Pulping, singeing on one side, oxygen bleaching, setting, mercerizing, pad dyeing, dyeing and double dyeing of the same color, finishing.

[0050] The front and back of the cloth are required to be consistent, the seam head is straight, and it is required to be flat, straight, neat, and firm. The needle density is 40 needles / 15cm, and the two sides are encrypted to 4 needles / cm to prevent wrinkles, weft skew, and curls during printing and dyeing. side.

[0051] The single-side singeing process is specifically gas singeing, singeing twice on the front of the two burners, and the speed is 80m / min.

[0052] The combined desizing and bleaching production line is used for...

Embodiment 3

[0062] Cotton-polyester interwoven spandex core-spun elastic fabric, including cotton, polyester and spandex, has 16 counts of cotton in the warp direction, 150D low-elastic network yarn and 70D spandex covered yarn in the weft direction, and its dyeing process includes steps in turn: turning the cloth, returning Pulping, singeing on one side, oxygen bleaching, setting, mercerizing, pad dyeing, dyeing and double dyeing of the same color, finishing.

[0063] The front and back of the fabric are required to be consistent, the seam head is straight, and it is required to be flat, straight, neat, and firm. The needle density is 45 needles / 15cm, and the two sides are densely encrypted to 6 needles / cm to prevent wrinkles, weft skew, and curls during printing and dyeing. side.

[0064] The single-side singeing process is specifically gas singeing, singeing twice on the front of the two burners, and the speed is 85m / min.

[0065] The combined desizing and bleaching production line is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com