optical equipment

A technology for optical equipment and optical components, applied in the directions of optics, optical components, nonlinear optics, etc., can solve the problem of difficult heat transfer of the thin-film heat source 422, and achieve the effect of eliminating the deterioration of wavelength conversion characteristics, preventing characteristic changes, and preventing deformation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

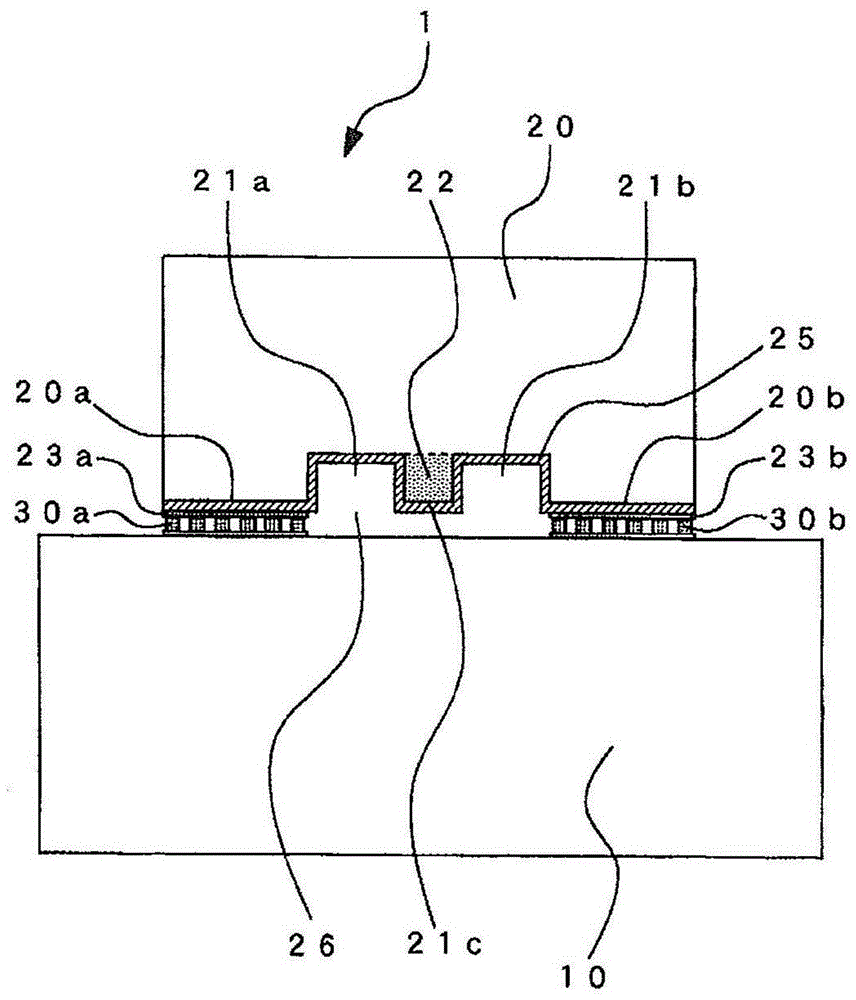

[0066] An optical device equipped with a wavelength conversion element that converts incident light into a second harmonic wave will be described as an example with reference to the following drawings. However, please note that the technical scope of the present invention is not limited to the drawings and the embodiments described below.

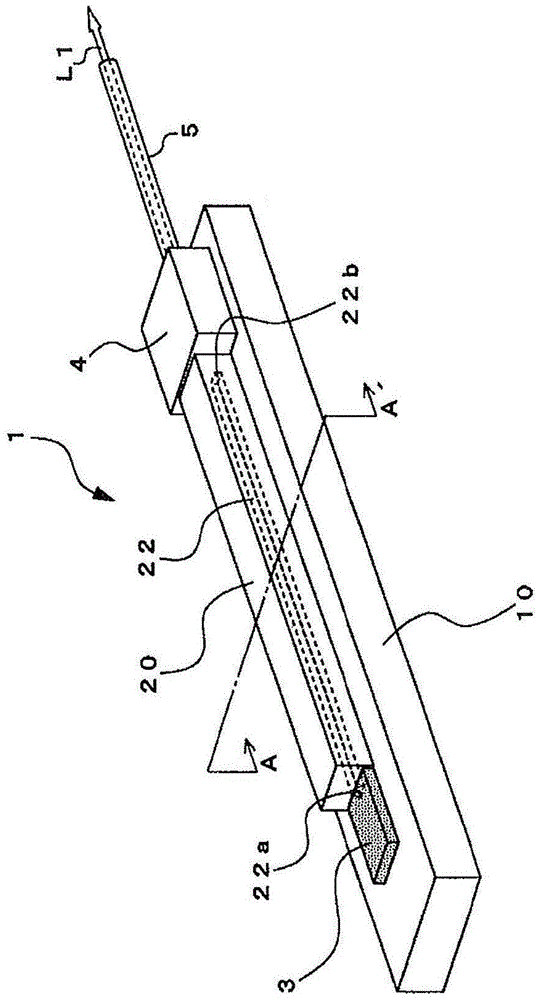

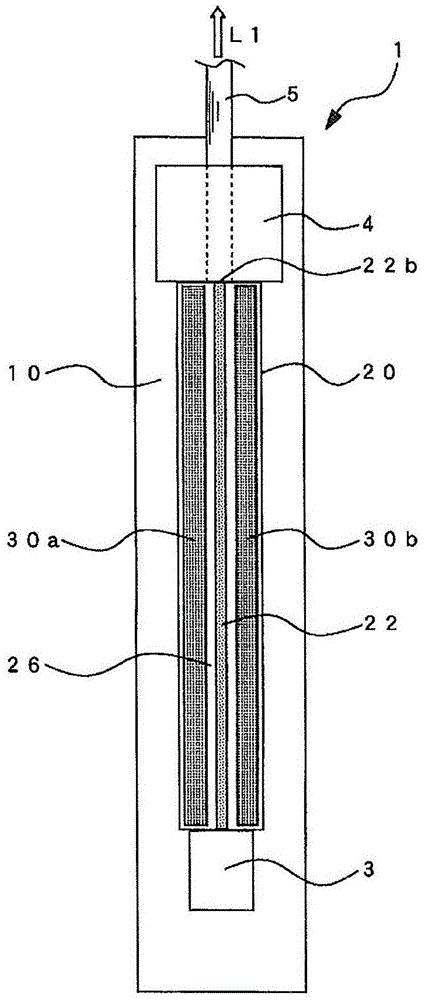

[0067] figure 1 It is a schematic diagram showing the overall structure of the optical device 1 .

[0068] Such as figure 1 As shown, the optical device 1 includes: a plate-shaped silicon substrate 10, a wavelength conversion element 20 as an optical element bonded to the silicon substrate 10, a semiconductor laser 3 bonded to the silicon substrate 10 to emit laser light, and a semiconductor laser 3 bonded to the silicon substrate. 10, an auxiliary substrate 4 for fixing the optical fiber 5, and the like. The optical device 1 is equipped with a ridge-type wavelength conversion element as an optical element, and a heat source for temper...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com