A kind of k465 alloy isothermal forging die processing method

A processing method and isothermal forging technology, applied in the field of warm forging die processing, can solve the problems that ordinary mechanical processing cannot be completed, and achieve the effects of saving raw materials, reducing costs, and reducing wear

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

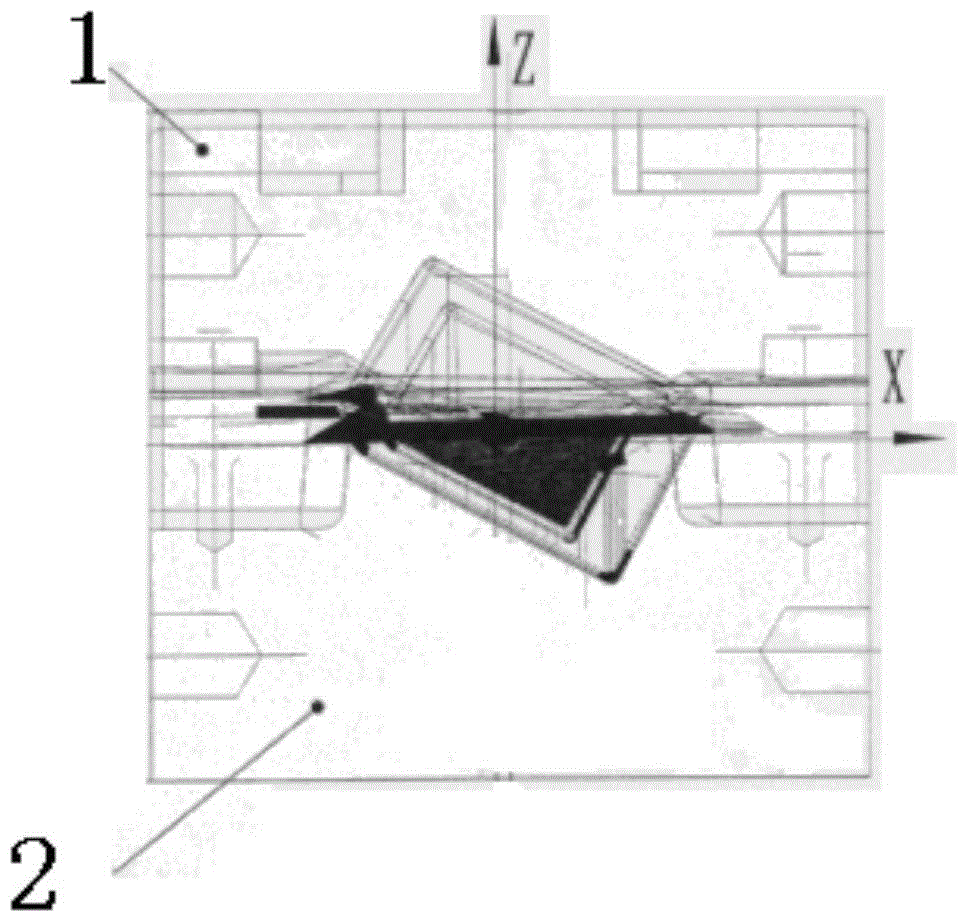

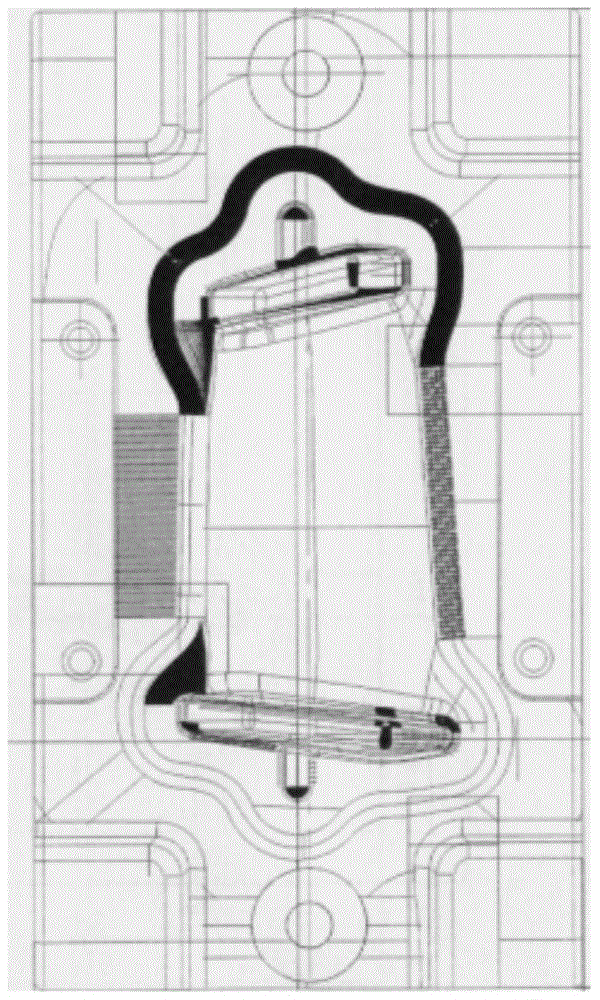

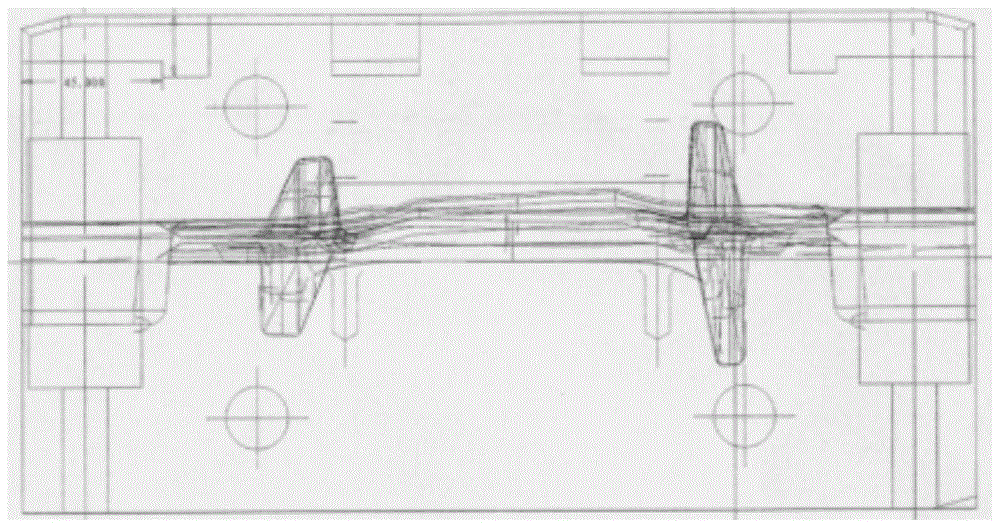

Image

Examples

Embodiment 1

[0023] This embodiment provides a K465 alloy isothermal forging die processing method, which is characterized in that: the K465 alloy isothermal forging die processing method adopts an electrical machining method;

[0024] The first is billet casting to control the machining allowance; then the riser is cut off by wire cutting, the six sides are ground by vertical mill, and all the profiles are processed by the profile electrodes and the electrodes of each hole; finally, the profile is detected by three coordinates.

[0025] In order to ensure mold precision and processing efficiency, profile electrodes are divided into 2 pieces: rough punching and precision punching, and the discharge gap is cut to 0.6mm and 0.2mm on each side respectively. The main process is as follows:

[0026] 1) Cutting material: 2 pieces of K403 castings;

[0027] 2) Vertical mill: Guarantee the requirements of the drawing on all sides, and the upper and lower sides can be flat to "∥⊥"≯0.02;

[0028] 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com