Processing method and processing apparatus for garbage leachate

A technology of landfill leachate and treatment method, which is applied in the field of sewage treatment in the discipline of environmental engineering. It can solve the problems of landfill leachate discharge up to standard, high operating costs, and long treatment cycle, etc., and achieve outstanding decolorization effect, reduce treatment cost, and low operating cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The treatment equipment of embodiment 1 landfill leachate:

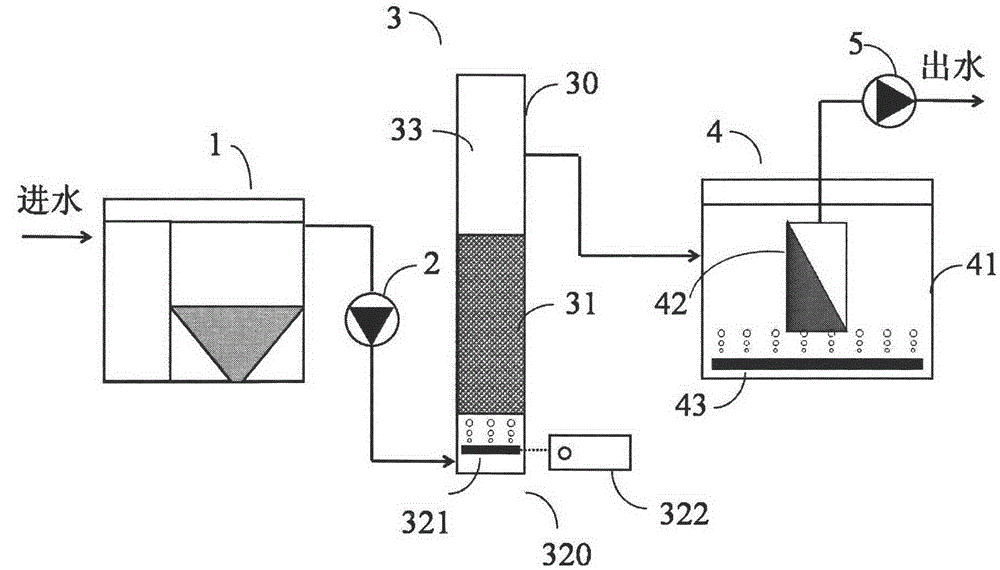

[0045] Such as figure 1 As shown, the treatment equipment of a landfill leachate provided by the present invention includes a coagulation-sedimentation integrated tank 1, a first water pump 2, an ozone / activated carbon oxidation device 3, and a submerged membrane bioreactor connected in sequence 4 and a second water pump 5; This ozone / activated carbon oxidation device 3 is an ozone oxidation tower 30 provided with an activated carbon packing part 31, and the bottom of this ozone oxidation tower 30 is provided with an ozone oxidation part 320, and these ozone oxidation parts 320 are An ozone diffuser 321 and an ozone generator 322; This activated carbon packing part 31 is located at the middle part of this ozone oxidation tower 30, and the top of this ozone oxidation tower 30 is an outflow part 33; This submerged membrane bioreactor 4 comprises a Membrane bioreaction tank 41 , a membrane module 42 and an aerat...

Embodiment 2

[0049] The treatment method of embodiment 2 landfill leachate

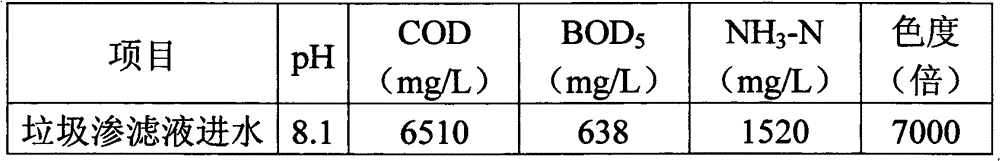

[0050] The water quality components of landfill leachate in a certain place are shown in Table 1.

[0051] Table 1 Landfill leachate influent water quality

[0052]

[0053] The processing method of landfill leachate: adopt the processing equipment of the landfill leachate of embodiment 1 to carry out following steps:

[0054] (1) Coagulation pretreatment: pass the landfill leachate into the coagulation-sedimentation integrated tank 1, add ferric chloride, and the dosage of ferric chloride is based on Fe 3+ Concentration 3.0mmol / L The molar weight of the landfill leachate, carry out the coagulation reaction for 30 minutes, and let it stand for 60 minutes;

[0055] (2) Ozone / activated carbon oxidation treatment: adopt the first water pump 2 to pass the supernatant liquid obtained after the coagulation pretreatment into the ozone / activated carbon oxidation device 3, and carry out the gas-liquid-solid three-phas...

Embodiment 3

[0059] The treatment method of embodiment 3 landfill leachate

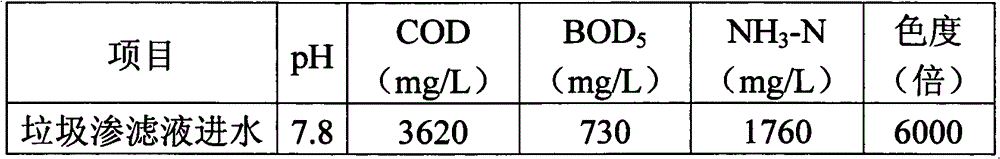

[0060] The water quality components of landfill leachate in a certain place are shown in Table 2.

[0061] Table 2 Landfill leachate influent water quality

[0062]

[0063] The processing method of landfill leachate: adopt the processing equipment of the landfill leachate of embodiment 1 to carry out following steps:

[0064] (1) Coagulation pretreatment: pass the landfill leachate into the coagulation-sedimentation integration pool 1, add polyferric sulfate, and the consumption of polyferric sulfate is based on Fe 3+ Concentration 2.0mmol / L The molar weight of the landfill leachate, carry out the coagulation reaction for 25min, and let it stand for 50min;

[0065] (2) Ozone / activated carbon oxidation treatment: adopt the first water pump 2 to pass the supernatant obtained after the coagulation pretreatment into the ozone / activated carbon oxidation device 3, and carry out the gas-liquid-solid three-phase rea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com