A kind of asphalt pavement joint filling glue and preparation method thereof

A technology of asphalt pavement and joint glue, which is applied to chemical instruments and methods, other chemical processes, building components, etc., can solve the problems of long preparation process and unfavorable industrial production, achieve high softening point, and be easy to operate , the effect of reasonable price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

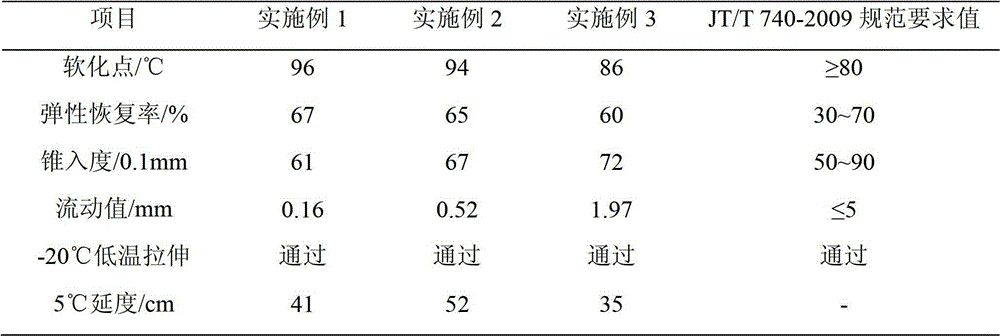

[0027] Embodiment 1, prepare joint glue

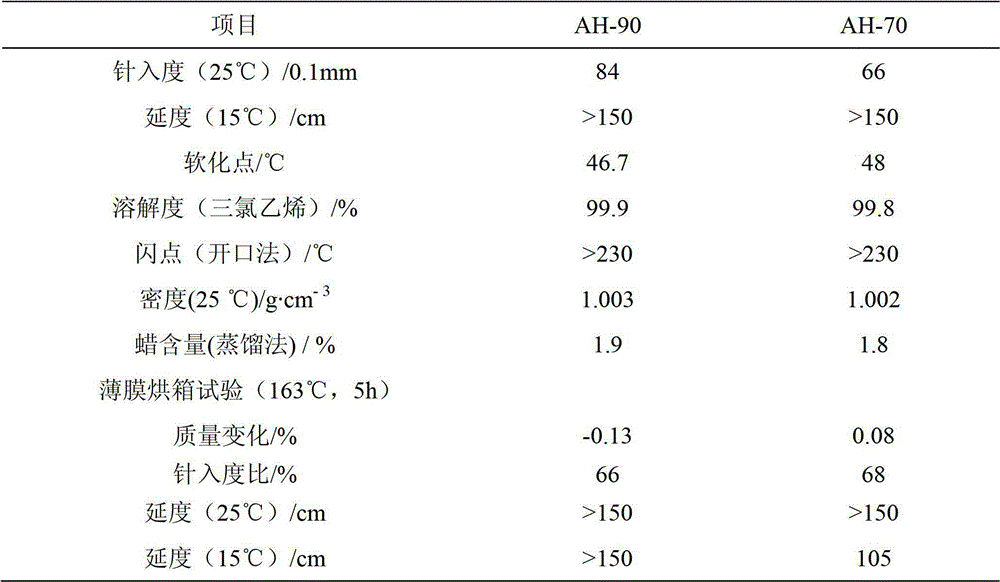

[0028] Using the AH-90 bitumen produced by China Shipping Asphalt Co., Ltd. as raw material (see Table 1 for properties), and using the third-line extraction oil produced by China Shipping Asphalt Co., Ltd. as a compatibilizer, research on heavy oil processing engineering in CNOOC (Qingdao) Center Co., Ltd. (hereinafter referred to as "Qingdao Research Center") small test device for testing.

[0029] Weigh 600g of asphalt, 200g of compatibilizer, and 200g of modifier (a mixture of styrene-butadiene-styrene block copolymer, SBR, and rubber powder, the ratio of mass and number of parts is 2:1:1), and the asphalt Heat to 140°C, then add modifier and compatibilizer heated to 40°C to the asphalt for stirring and swelling, wherein the temperature of stirring and swelling is 190°C, and the time is 30min; after swelling, the sample is sheared, sheared The temperature is 180°C, and the shearing time is 45min; after shearing, slowly add 8g of s...

Embodiment 2

[0031] Embodiment 2, preparation of caulking glue

[0032] The AH-70 bitumen produced by China Shipping Asphalt Co., Ltd. was used as raw material (see Table 1 for properties), and the third-line extraction oil produced by China Shipping Asphalt Co., Ltd. was used as a compatibilizer. The test was carried out in the small test device of Qingdao Research Center.

[0033] Weigh 550g of asphalt, 230g of compatibilizer, and 220g of modifier (a mixture of styrene-butadiene-styrene block copolymer, SBR, and rubber powder, with a mass ratio of 2:1.2:0.8), and heat the asphalt to 150°C, then add the modifier and compatibilizer heated to 60°C into the asphalt for stirring and swelling, wherein the temperature of stirring and swelling is 200°C, and the time is 60min; after swelling, the sample is sheared, and the shearing temperature is 200°C, the shearing time is 120min; after shearing, slowly add 8g of stabilizer (a mixture of sulfur, organic vulcanizing agent and rubber powder, the m...

Embodiment 3

[0035] Embodiment 3, preparation of caulking glue

[0036] The AH-90 asphalt produced by China Shipping Asphalt Co., Ltd. was used as raw material (see Table 1 for properties), and the third-line extraction oil produced by China Shipping Asphalt Co., Ltd. was used as a compatibilizer. The test was carried out in the pilot plant of Qingdao Research Center.

[0037] Weigh 30kg of asphalt, 10kg of compatibilizer, and 10kg of modifier (a mixture of styrene-butadiene-styrene block copolymer, SBR, and rubber powder, with a mass ratio of 1:1:1), and heat the asphalt to 150°C, then add the modifier and the compatibilizer heated to 50°C into the asphalt for stirring and swelling, the temperature of stirring and swelling is 185°C, and the time is 45min; after swelling, the sample is sheared, and the shearing temperature is 180°C ℃, the shearing time is 90min; after shearing, slowly add 400g of stabilizer (a mixture of sulfur, organic vulcanizing agent and rubber powder, the mass ratio i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| softening point | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com