Molybdate matrix up-conversion luminescence fluorescent powder and preparation method thereof

A fluorescent powder, molybdate technology, applied in the field of fluorescent powder

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

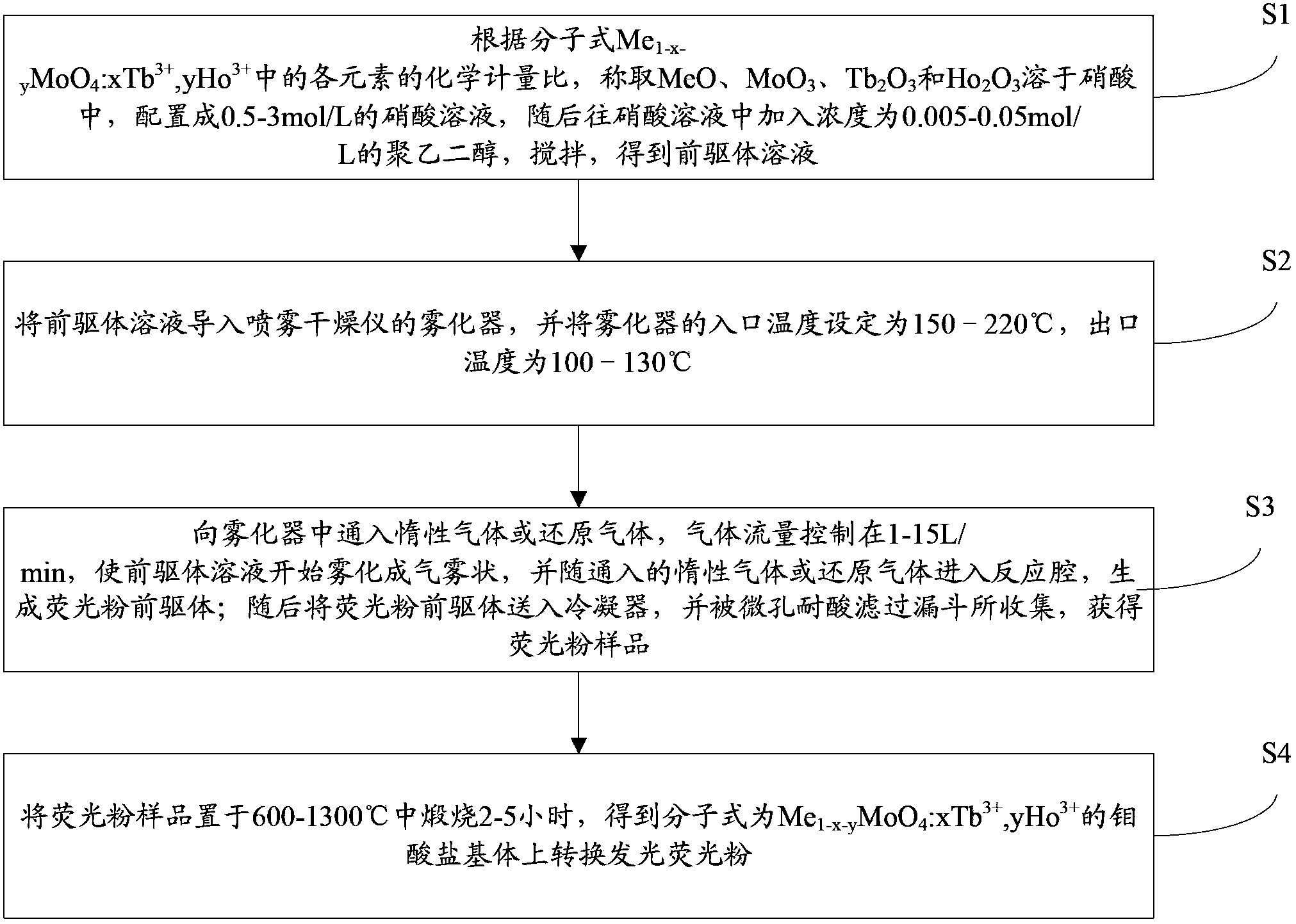

[0022] The preparation method of the molybdate matrix up-conversion luminescent phosphor, such as figure 1 , including the following steps:

[0023] S1, according to the molecular formula Me 1-x-y MoO 4 :xTb 3+ ,yHo 3+ The stoichiometric ratio of each element in, weigh MeO, MoO 3 , Tb 2 o 3 and Ho 2 o 3 Soluble in nitric acid, configured as total cation (ie Mg 2+ 、Mo 6+ , Tb 3+ and Ho 3+ ) is a nitric acid solution of 0.5-3 mol / L, then adding polyethylene glycol with a concentration of 0.005-0.05 mol / L as a dispersant to the nitric acid solution, and stirring to obtain a precursor solution;

[0024] S2. Lead the precursor solution into the atomizer of the spray dryer, and set the inlet temperature of the atomizer to 150-220°C and the outlet temperature to 100-130°C;

[0025] S3. Pass an inert gas (such as at least one of argon and nitrogen) or a reducing gas into the atomizer, and control the gas flow rate at 1~15L / min, so that the precursor solution starts to be ...

Embodiment 1

[0036] Weigh MgO, MoO 3 ,Tb 2 o 3 and Ho 2 o 3 The powder, the molar ratio of which is 0.96:1:0.015:0.005, is dissolved in nitric acid to prepare a nitric acid solution with a total cation of 1.5mol / L, and 0.01mol / L polyethylene glycol is added to the nitric acid solution as a dispersant , to obtain the precursor solution.

[0037] Then, put the precursor solution into the atomizer of the spray dryer, the inlet temperature is 180°C, and the outlet temperature is 110°C.

[0038] Subsequently, 5 L / min of argon gas is introduced into the atomizer, and the precursor solution enters the quartz reaction chamber with the argon carrier gas, and the phosphor precursor is generated in the reaction chamber; the phosphor precursor enters the condenser with the airflow, Finally, it is collected by a microporous acid-resistant filter funnel to obtain a fluorescent powder sample.

[0039] Finally, the phosphor powder sample was calcined in a temperature-programmed furnace for 3 hours a...

Embodiment 2

[0041] Weigh MgO, MoO 3 ,Tb 2 o 3 and Ho 2 o 3 The powder, whose molar ratio is 0.9:1:0.03:0.02, is dissolved in nitric acid to prepare a nitric acid solution with a total cation of 3mol / L, and 0.05mol / L polyethylene glycol is added to the nitric acid solution as a dispersant, Obtain the precursor solution.

[0042] Then, put the precursor solution into the atomizer of the spray dryer, the inlet temperature is 220°C, and the outlet temperature is 130°C.

[0043] Subsequently, nitrogen gas of 15 L / min is introduced into the atomizer, and the precursor solution enters the quartz reaction chamber with the nitrogen carrier gas, and the phosphor precursor is generated in the reaction chamber, and the phosphor precursor enters the condenser with the air flow, and is finally Microporous acid-resistant filter funnel collected to obtain phosphor samples.

[0044] Finally, the phosphor powder sample was calcined in a temperature-programmed furnace for 5 hours at a temperature of 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com