Pre-etherification reaction method in light petrol etherification technology

A light gasoline, chemical reaction technology, applied in the petroleum industry, processing hydrocarbon oil, etc., can solve the problems of shortening the process flow, achieve the effects of shortening the process flow, realizing continuous production, and high sulfonic acid group content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

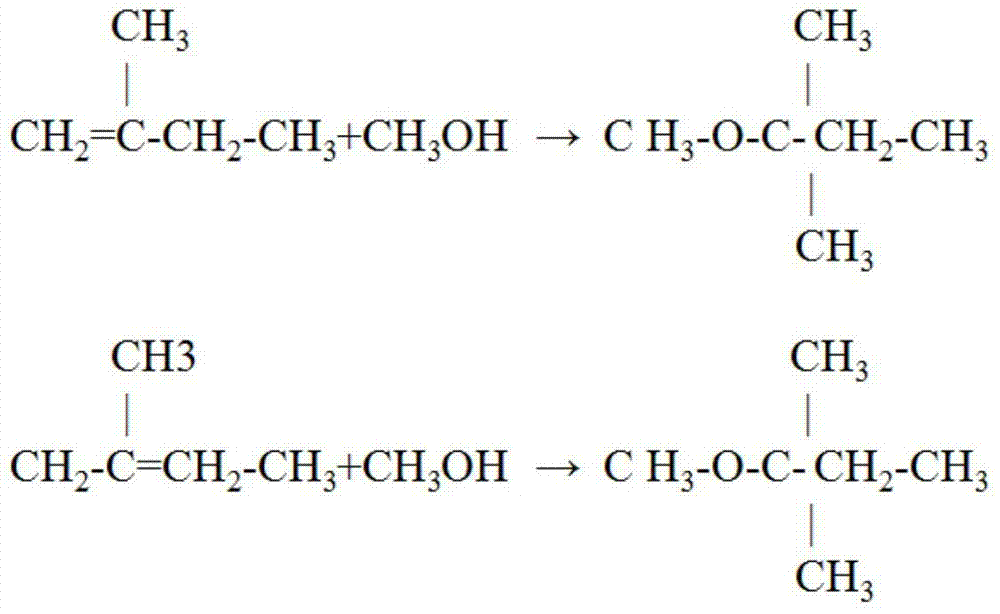

Method used

Image

Examples

Embodiment 1

[0024] Equipment: XS-T type external membrane reactor 10L, produced by Nanjing University of Technology, the structure includes a reactor and a ceramic membrane filter.

[0025] Process flow: add light gasoline, methanol and catalyst into the above-mentioned external membrane reactor according to the weight ratio of 1:0.1:5, light gasoline and methanol are mixed after the reaction materials are preheated, and are carried out in the reactor at a set molar ratio Continuous etherification reaction. The catalyst is a D006-7 resin catalyst with a particle size of 70-100 mesh produced by 2L Kairui Chemical Co., Ltd., the water in the catalyst is replaced with methanol to a water content of ≤1%, the reaction temperature is 80°C, and the space velocity is 1h -1 , the mass ratio of alcohol to oil is 0.01, and the reaction pressure is 0.4MPa. The reaction mixture is pumped from the bottom of the reactor to the ceramic membrane filter. Under a certain pressure difference, the separation ...

Embodiment 2

[0027] Reaction temperature 90 ℃, others are the same as embodiment 1. The product number obtained by pre-etherification is KRB-2.

Embodiment 3

[0029] Airspeed 3h -1 , other with embodiment 1. The product number obtained by pre-etherification is KRB-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com