Wood tar-modified epoxy resin curing agent, production method thereof and epoxy resin anticorrosive coating

A technology of epoxy resin curing and production method, which is applied in epoxy resin coatings, coatings and other directions to achieve the effects of reducing environmental pollution, improving various properties, and using large quantities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation Embodiment 1

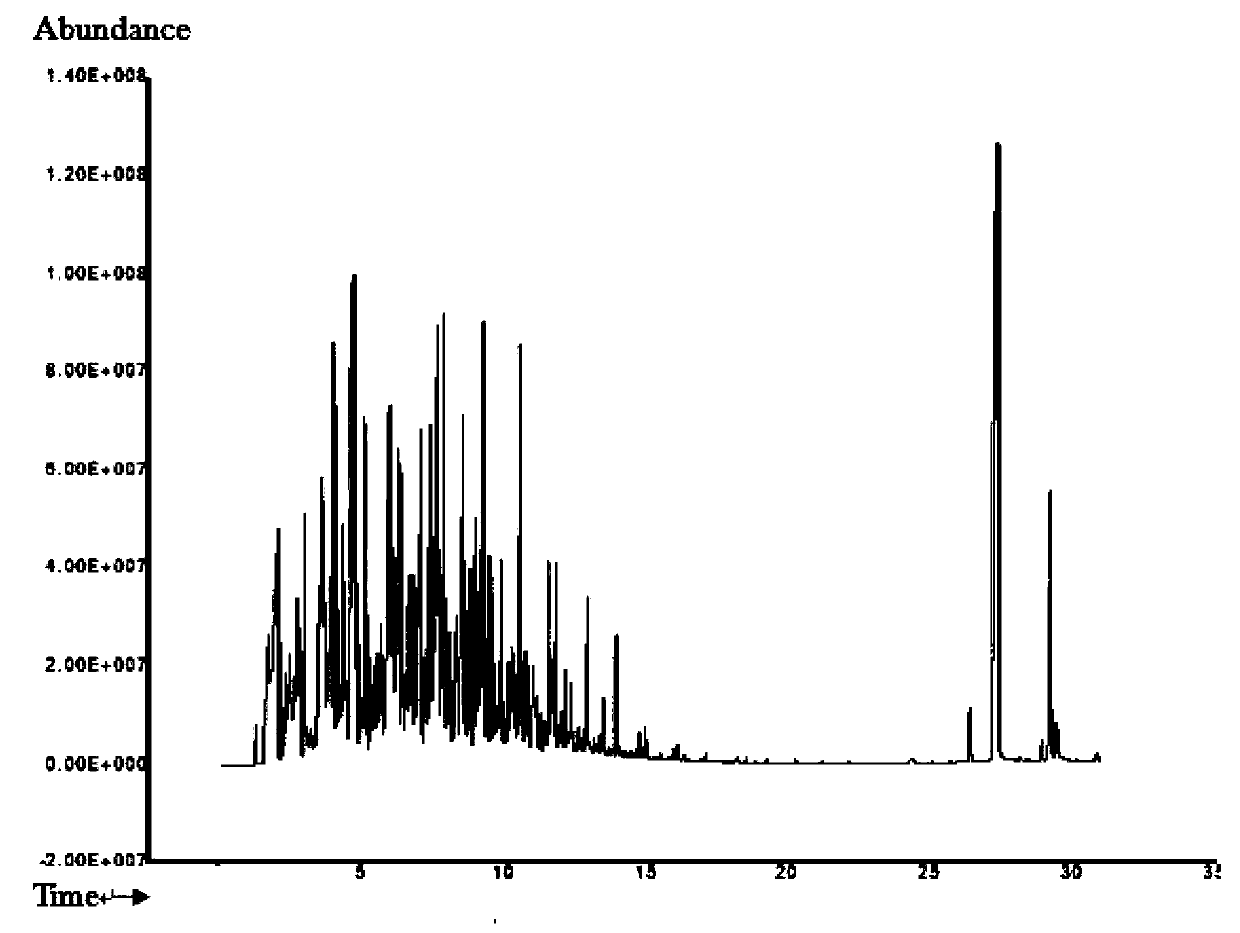

[0028] (1) Treatment of crude wood tar: distill the crude wood tar under reduced pressure at 0.085MPa at 140°C, stop the decompression after 3 hours, and obtain refined wood tar, which is identified by gas chromatography and mass spectrometry (GC-MS method) The content of phenolic substances in the refined wood tar reaches 30%.

[0029] (2) Preparation: Heat 37.5 grams of fine wood tar, 21 grams of 37% formaldehyde solution by mass percentage, and 6 grams of xylene to 90 ° C, keep warm for 1.5 hours, and then mix 14 grams of xylene and 54.5 g of triethylenetetramine Add dropwise, and finally keep the reaction at 80°C for 2h.

[0030] (3) Suction filtration: The above reaction product was subjected to vacuum suction filtration at 085 MPa and 90° C. until no liquid flowed out to obtain epoxy resin curing agent 1 .

[0031] The raw material components of epoxy curing agent 1 are: 37.5 grams of fine wood tar, 21 grams of formaldehyde solution, 54.5 grams of triethylenetetramine a...

preparation Embodiment 2

[0034] (1) Treatment of crude wood tar: distill the crude wood tar under reduced pressure at 0.01MPa at 123°C, and stop the decompression after 3 hours to obtain refined wood tar, which is identified by gas chromatography and mass spectrometry (GC-MS method) The content of phenolic substances in the refined wood tar reaches 32%.

[0035] (2) Preparation: Heat 50 grams of wood tar, 35 grams of 37% formaldehyde solution, and 28 grams of xylene to 60° C., keep the temperature for 1.5 hours, then add a mixture of 12 grams of xylene and 37 g of triethylenetetramine dropwise, Finally, at 50° C., keep warm for 3 h.

[0036] (3) Suction filtration: the above reaction product was subjected to vacuum filtration at 0.1 MPa and 85° C. until no liquid flowed out to obtain epoxy resin curing agent 2 .

[0037] The raw material components of the epoxy curing agent 2 are: 50 grams of fine wood tar, 35 grams of formaldehyde solution, 37 grams of triethylenetetramine and 40 grams of xylene, wh...

preparation Embodiment 3

[0040] (1) Treatment of crude wood tar: distill the crude wood tar under reduced pressure at 0.01MPa at 123°C, and stop the decompression after 3 hours to obtain refined wood tar, which is identified by gas chromatography and mass spectrometry (GC-MS method) The content of phenolic substances in the refined wood tar reaches 35%.

[0041] (2) Preparation: Heat 37.5 grams of wood tar, 26 grams of 37% formaldehyde solution, and 12 grams of xylene to 90° C., keep warm for 1.5 hours, then mix 28 grams of xylene and 51.7 grams of diethylenetriamine and add them dropwise , at 50 ° C, heat preservation reaction 3h.

[0042] (3) Suction filtration: The above reaction product was subjected to vacuum filtration at 0.1 MPa and 85° C. until no liquid flowed out to obtain epoxy resin curing agent 3 .

[0043]The raw material components of epoxy curing agent 3 are: 37.5 grams of refined wood tar, 26 grams of formaldehyde solution, 51.7 grams of diethylenetriamine and 40 grams of xylene, whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com