A method for removing iron from recycled aluminum

A technology of recycled aluminum and silicon-aluminum, which is applied in the field of purification of recycled aluminum melts, can solve the problems of low absorption rate, failure to mention the mechanical properties of recycled aluminum, and unfavorable utilization of resources, etc., to achieve reduced iron content and good dispersion , the effect of grain refinement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

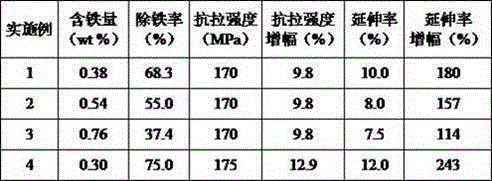

Embodiment 1

[0020] Weigh 50% of the Al-5%B master alloy and 50% of the Al-30%Mn master alloy according to 1.5% of the mass of regenerated silicon-aluminum aluminum, and preheat at 200°C for 60 minutes; after heating the regenerated silicon-aluminum aluminum to 400°C, Keep warm for 15 minutes, then raise the temperature to 700°C; after the molten aluminum in the crucible is completely melted, add the intermediate alloy into the molten aluminum, stir the melt slowly with a titanium stirring rod, and let it stand for 1 hour after the intermediate alloy is melted; , the mold is fixed on a vibrating table with a vibration frequency of 10 Hz and an amplitude of 10 cm, and the entire casting and cooling are completed under mechanical vibration.

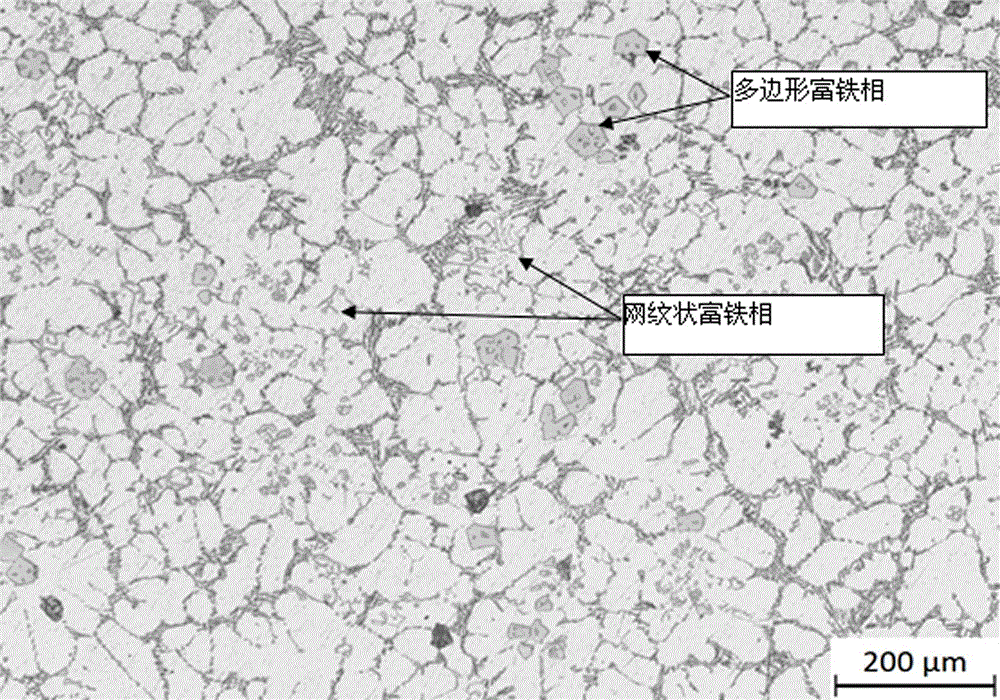

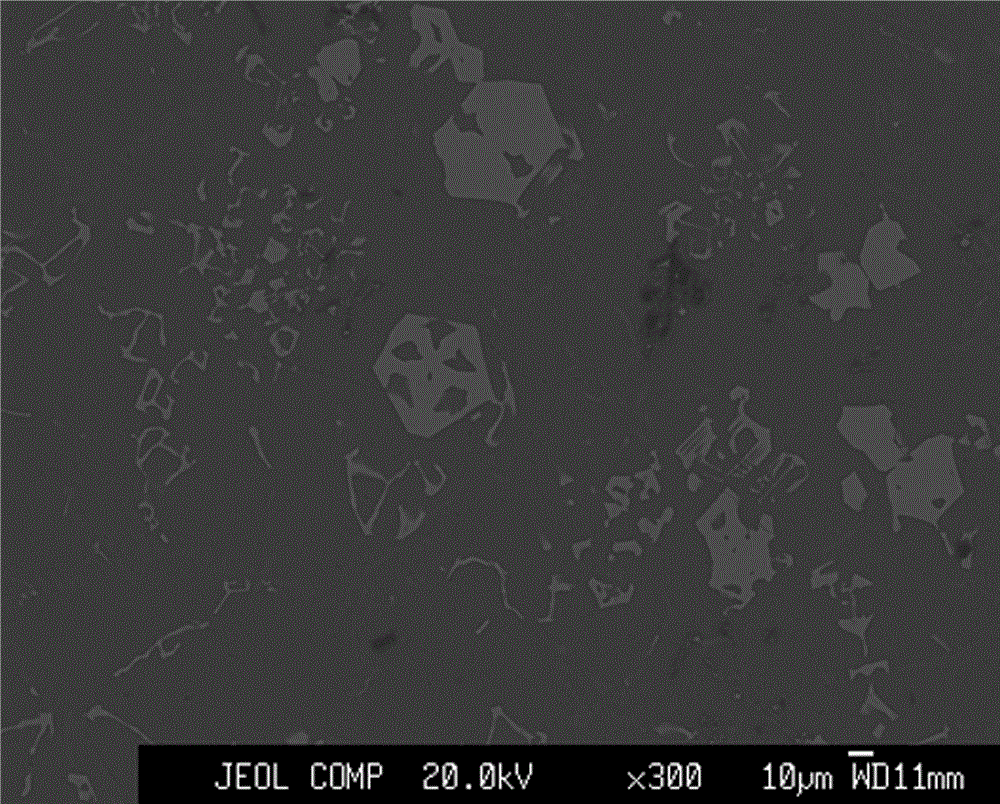

[0021] After the iron removal treatment, no dendrites were found in the metallographic structure of the casting, and the iron-rich phase mainly took the form of polygon and network, see figure 1 and figure 2 . The atomic ratio of Mn / Fe in the polygon...

Embodiment 2

[0023] Weigh 60% Al-5%B master alloy and 40% Al-60%Mn master alloy according to 1.0% of silicon-aluminum regenerated aluminum mass, preheat at 180°C for 45 minutes; heat silicon-aluminum regenerated aluminum to 400°C, Keep warm for 25 minutes, then raise the temperature to 700°C; after the molten aluminum in the crucible is completely melted, add the intermediate alloy into the molten aluminum, stir the melt slowly with a titanium stirring rod, and let it stand for 1.5 hours after the intermediate alloy is melted; , Fix the mold on a vibrating table with a vibration frequency of 20 Hz and an amplitude of 10 cm. The entire casting and cooling are completed under mechanical vibration.

Embodiment 3

[0025] Weigh 70% Al-3%B master alloy and 30% Al-70%Mn master alloy according to 0.5% of silicon-aluminum regenerated aluminum mass, preheat at 220°C for 20 minutes; heat silicon-aluminum regenerated aluminum to 400°C, Keep warm for 25 minutes, then raise the temperature to 700°C; after the molten aluminum in the crucible is completely melted, add the intermediate alloy into the molten aluminum, stir the melt slowly with a titanium stirring rod, and let it stand for 0.5 hours after the intermediate alloy is melted; when casting , Fix the mold on a vibrating table with a vibration frequency of 30 Hz and an amplitude of 5 cm. The entire casting and cooling are completed under mechanical vibration.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com