Drier coating film

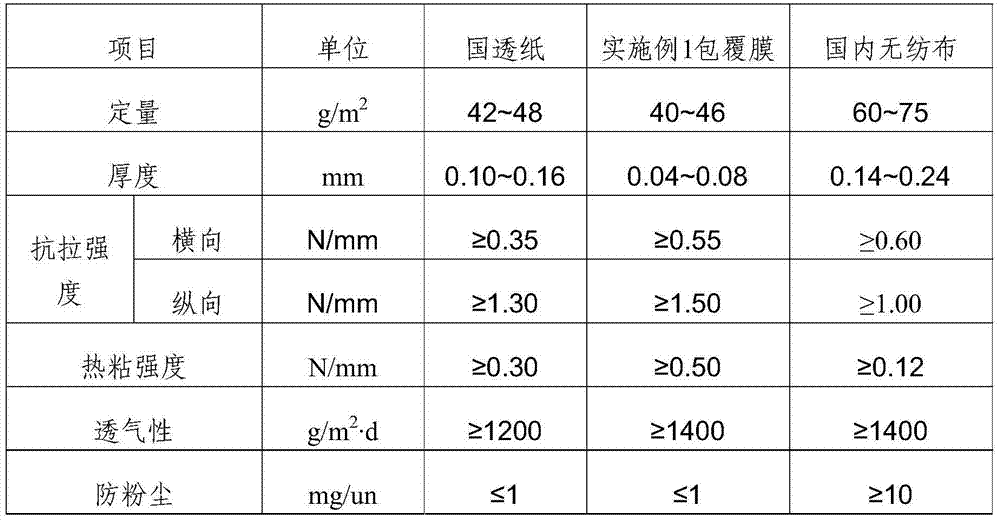

A technology of coating film and desiccant, which is applied in the direction of reinforcing agent addition, fiber dispersant addition, lamination, etc., can solve the problem of poor dust resistance of non-woven fabrics, poor strength of national permeable paper or non-woven fabrics, and inability to adapt, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] Embodiment 1 Preparation of desiccant coating film of the present invention

[0039] The first step: prepare tea filter paper to prepare materials, mix and beat:

[0040] Add 2 parts of bleached kraft softwood chemical pulp, 2 parts of cotton pulp, 0.02 part of wet strength agent, and 0.02 part of dispersant into 100 parts of water to make a slurry. The slurry is passed through the net to make wet paper for use. Add 1 part of polymer plastic fiber, 2 parts of bleached kraft softwood chemical pulp, 0.02 part of wet strength agent, and 0.02 part of dispersant into 100 parts of water to make slurry, and the slurry is passed through the net to make wet paper for use.

[0041] The second step: wet papermaking:

[0042] Press the above two kinds of wet paper together, dry, and calender to make 28g / m 2 Heat-sealable tea filter paper.

[0043] Step 3: Composite:

[0044] The above 28g / m 2 Heat-sealed tea filter paper with 15g / m 2 Spun-bonded non-woven fabric composed of p...

Embodiment 2

[0045] Example 2 Preparation of desiccant coating film of the present invention

[0046] The first step: prepare tea filter paper to prepare materials, mix and beat:

[0047] Add 1 part of bleached kraft softwood chemical pulp, 3 parts of cotton pulp, 0.02 part of wet strength agent, and 0.02 part of dispersant to 100 parts of water to make a slurry, and the slurry is passed through the net to make wet paper for use.

[0048] Add 2 parts of polymer plastic fiber, 2 parts of bleached kraft softwood chemical pulp, 0.02 part of wet strength agent, and 0.02 part of dispersant into 100 parts of water to make slurry. The slurry is passed through the net to make wet paper for use.

[0049] The second step: wet papermaking:

[0050] Press the above two kinds of wet paper together, dry, and calender to make 38g / m 2 Heat-sealable tea filter paper.

[0051] Step 3: Composite:

[0052] The above 38g / m 2 Heat-sealed tea filter paper with 30g / m 2 Spun-bonded non-woven fabric composed ...

Embodiment 3

[0053] Example 3 Preparation of desiccant coating film of the present invention

[0054] The first step: prepare tea filter paper to prepare materials, mix and beat:

[0055] Add 1 part of bleached kraft softwood chemical pulp, 3 parts of cotton pulp, 0.02 part of wet strength agent, and 0.02 part of dispersant to 100 parts of water to make a slurry, and the slurry is passed through the net to make wet paper for use.

[0056] Add 2 parts of polymer plastic fiber, 1 part of bleached kraft softwood chemical pulp, 0.02 part of wet strength agent, and 0.02 part of dispersant into 100 parts of water to make slurry, and the slurry is passed through the net to make wet paper for use.

[0057] The second step: wet papermaking:

[0058] Press the above two kinds of wet paper together, dry, and calender to make 38g / m 2 Heat-sealable tea filter paper.

[0059] Step 3: Composite:

[0060] The above 38g / m 2 Heat-sealed tea filter paper with 15g / m 2 Spun-bonded non-woven fabric compos...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com