Fermented feed drying system

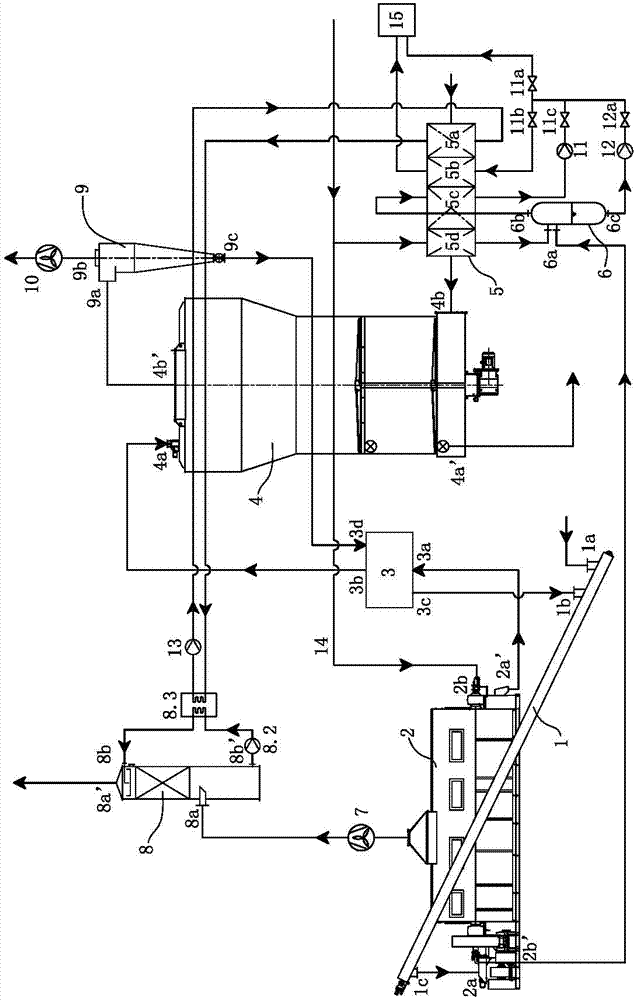

A fermented feed and drying system technology, applied in feed, dryer combination, drying solid materials, etc., can solve the problems of material sticking to the pipe wall, long drying time, uneven heating, etc., to avoid sticking pipe phenomenon, Good drying effect and high thermal efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The mass ratio of the sieve material entering the auxiliary feed port 1b of the feeding machine to the fresh fermented feed is 1:8, the moisture content of the fermented feed at the discharge port 2a' of the tube dryer is 20%, and the feed port of the tower dryer has a moisture content of 20%. The moisture content of the fermented feed in 4a' was 8%.

[0045] The temperature of the steam entering the steam inlet 2b of the tubular dryer is 135°C, the temperature of the condensed water at the condensed water outlet 2b' of the tubular dryer is 110°C, and the temperature of the fermented feed outlet at the outlet 2a' of the tubular dryer is 45°C; The hot air inlet temperature of the tower dryer air inlet 4b is 80°C, the exhaust air temperature of the tower dryer air outlet 4b' is 50°C, and the fermented feed outlet temperature of the tower dryer outlet 4a' is 60°C.

[0046] The exhaust air temperature of the tubular dryer 2 is 75°C, the exhaust air temperature of the waste ...

Embodiment 2

[0048] The mass ratio of the sieve material entering the auxiliary feeding port 1b of the feeding machine to the fresh fermented feed is 1:4, the moisture content of the fermented feed at the outlet 2a' of the tube dryer is 22%, and the outlet of the tower dryer The moisture content of the fermented feed in 4a' was 10%.

[0049] The temperature of the steam entering the steam inlet 2b of the tubular dryer is 138°C, the temperature of the condensed water at the condensed water outlet 2b' of the tubular dryer is 112°C, and the temperature of the fermented feed outlet at the outlet 2a' of the tubular dryer is 50°C; The hot air inlet temperature of the tower dryer air inlet 4b is 85°C, the exhaust air temperature of the tower dryer air outlet 4b' is 52°C, and the fermented feed outlet temperature of the tower dryer outlet 4a' is 65°C.

[0050] The exhaust air temperature of the tubular dryer 2 is 78°C, the exhaust air temperature of the waste heat absorption tower outlet 8a' is 57...

Embodiment 3

[0052] The mass ratio of the sieve material entering the auxiliary feed port 1b of the feeding machine to the fresh fermented feed is 3:8, the moisture content of the fermented feed at the discharge port 2a' of the tube dryer is 25%, and the discharge port of the tower dryer has a moisture content of 25%. The moisture content of the fermented feed in 4a' was 12%.

[0053] The temperature of the steam entering the steam inlet 2b of the tubular dryer is 140°C, the temperature of the condensed water at the condensed water outlet 2b' of the tubular dryer is 115°C, and the temperature of the fermented feed outlet at the outlet 2a' of the tubular dryer is 55°C; The hot air inlet temperature of the tower dryer air inlet 4b is 90°C, the exhaust air temperature of the tower dryer air outlet 4b' is 55°C, and the fermented feed outlet temperature of the tower dryer outlet 4a' is 70°C.

[0054] The exhaust air temperature of the tubular dryer 2 is 80°C, the exhaust air temperature of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com