Method and system for testing power semiconductor module packaging process

A technology of power semiconductors and testing methods, applied in the direction of semiconductor/solid-state device testing/measurement, semiconductor devices, electric solid-state devices, etc., can solve the problems of expensive equipment and unrepresentative X-ray detection technology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] The present invention will be described in detail below with reference to the accompanying drawings and specific embodiments.

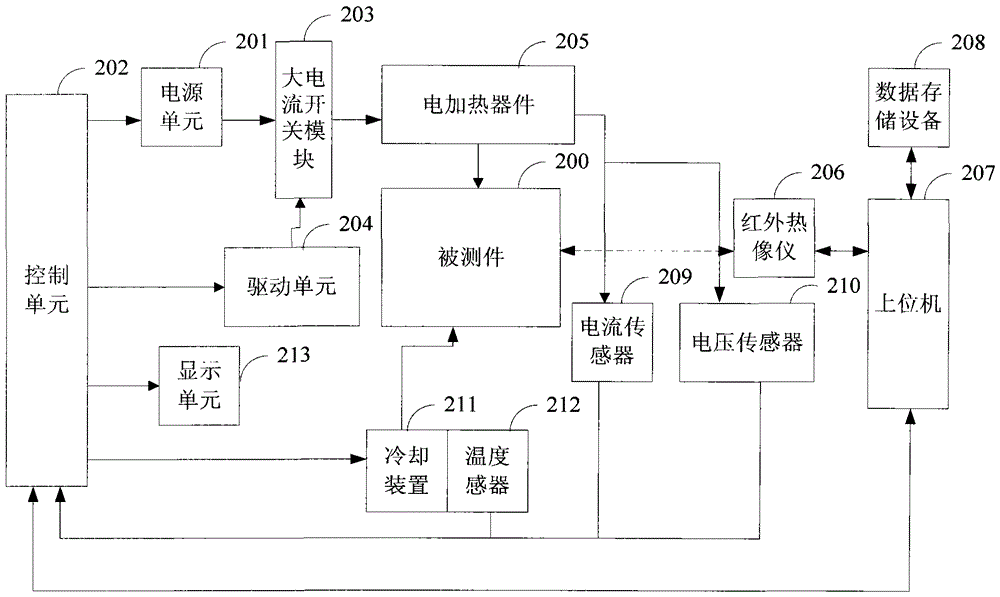

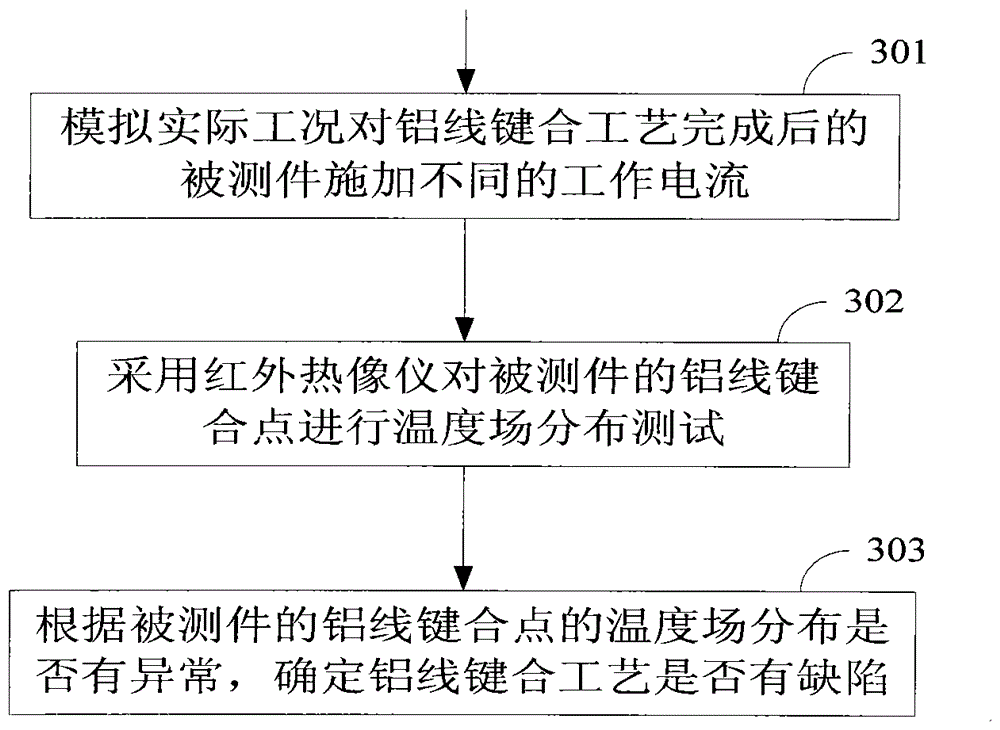

[0055] The present invention provides a test method and system for power semiconductor module chip welding process, a test method and system for power semiconductor module aluminum wire bonding process, and a packaging process including chip welding process and aluminum wire bonding process test The test method and system are used to realize the test of the chip bonding process and / or the aluminum wire bonding process under actual working conditions.

[0056] Examples are given below for description.

[0057] First, the test method of the power semiconductor module chip welding process of the present invention will be described.

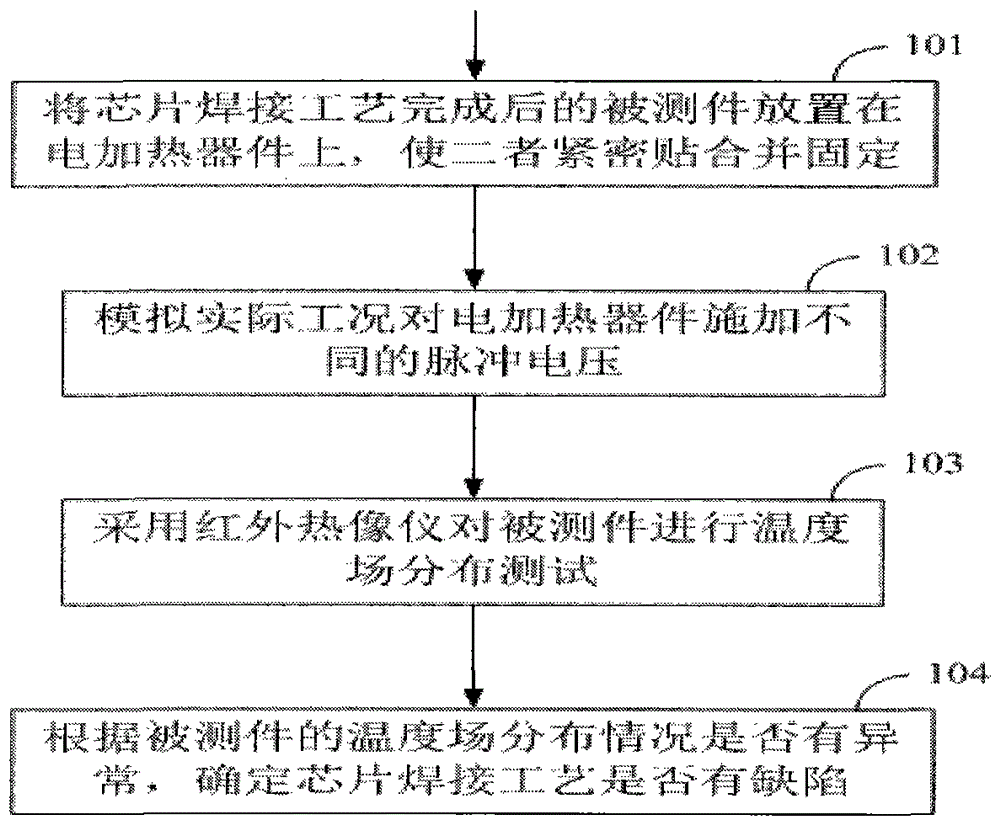

[0058] Such as figure 1 As shown, a preferred embodiment of the test method of the power semiconductor module chip welding process of the present invention comprises the following steps:

[0059] Step 101 , placing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com