A kind of flip-chip structure light-emitting diode and its preparation method

A light-emitting diode, flip-chip technology, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of mismatch of thermal expansion coefficients of polymer layers, the risk of isolation of insulating film 212, and leakage of LED structure sidewalls. The effect of reducing the probability, eliminating the possibility, and improving the reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

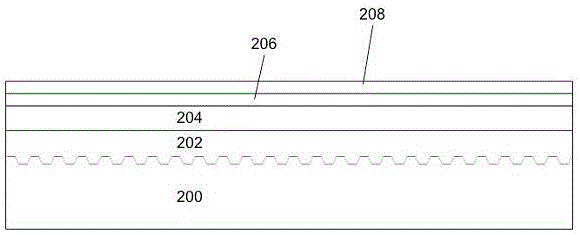

[0029] see Figure 9 The structure of the present invention includes a metal support substrate 220, an N-type ohmic contact metal layer 218, an insulating film 212, a reflective metal layer 210, a P-type semiconductor layer 208, a quantum well light-emitting layer 206, and an N-type semiconductor layer stacked in sequence from bottom to top. 204 and undoped layer 202. Multiple layers of metal are placed on and around the reflective metal layer 210 and extend to the side to serve as a P-type electrode 214 . The metal support substrate 220 is connected to the N-type semiconductor layer 204 and the non-doped layer 202 to form an N-type electrode.

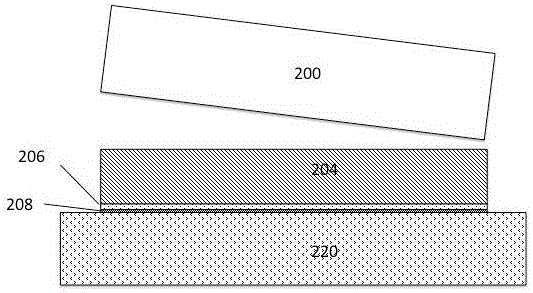

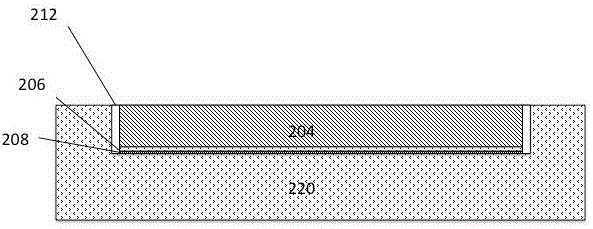

[0030] see Figure 3 to Figure 9 , the steps of the preparation method of the flip-chip light-emitting diode of the present invention are:

[0031] Select a patterned sapphire substrate 200, and grow an epitaxial layer with a thickness of 3~10 um on the sapphire substrate 200 with metal-organic chemical vapor deposition equipment. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com