Metamaterial, manufacturing method and metamaterial antenna

A metamaterial and antenna technology, applied in the field of metamaterials, can solve the problems of metal microstructure oxidation and easy peeling off of the protective layer, and achieve the effects of not easy to fall off, low loss, and good protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

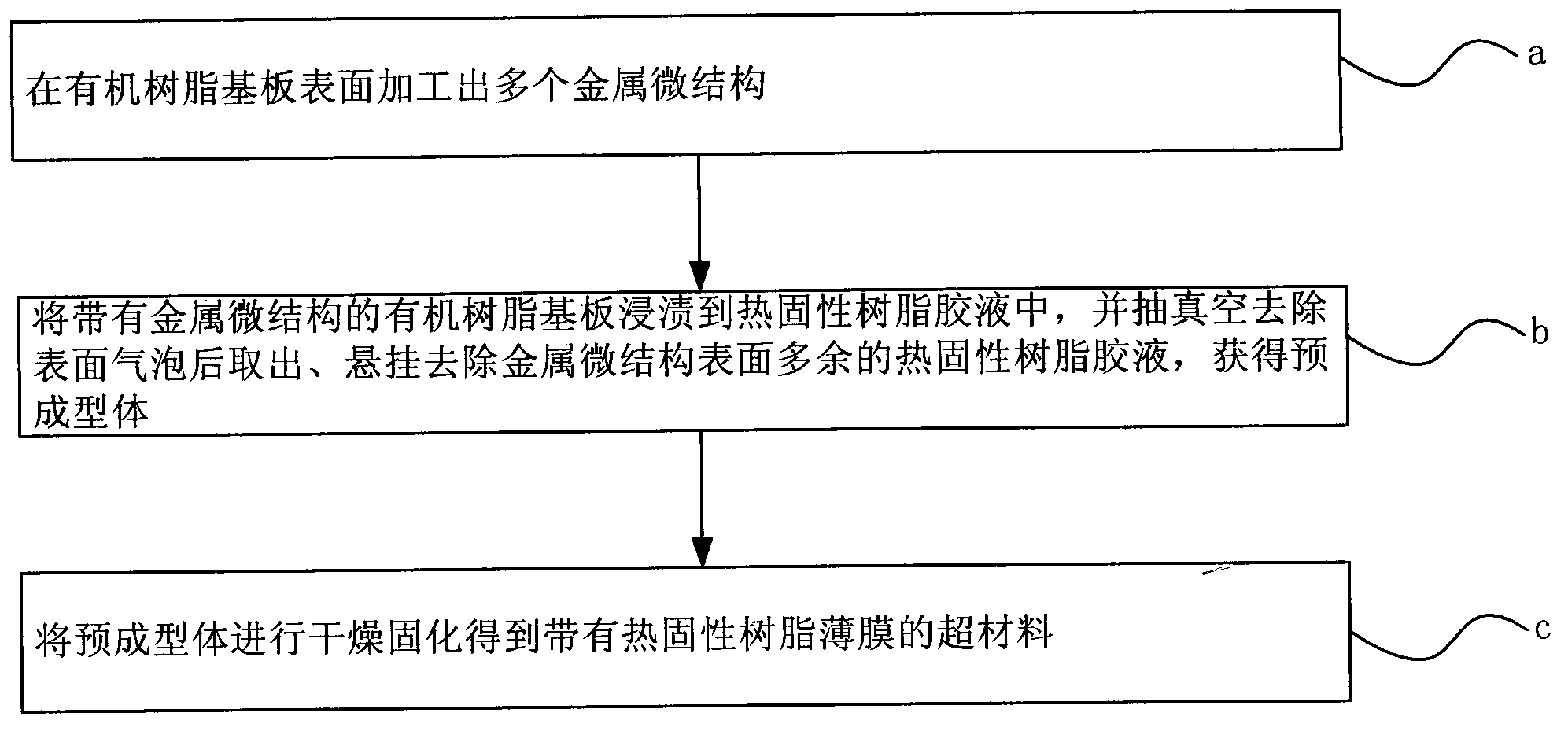

Method used

Image

Examples

Embodiment 1

[0031] Put the two-component epoxy resin glue with a viscosity of 5000cps in a container and stir evenly, impregnate the organic resin with the metal microstructure etched on the surface into the resin glue, and keep it vacuumed for 1 minute to remove the air bubbles on the surface, then take it out and hang it for 5 Remove the excess resin glue on the surface in 1 minute, send it to an oven for baking, and bake it at 80 degrees Celsius for 20 minutes to obtain a supermaterial with an epoxy resin film on the surface.

Embodiment 2

[0033] Put the acrylic resin glue solution with a viscosity of 1000cps in the container and stir evenly, impregnate the organic resin with metal microstructure etched on the surface into the resin glue solution, and keep vacuuming for 2 minutes to remove the air bubbles on the surface, then take it out and hang it for 3 minutes to remove the excess surface Remove the resin glue, send it to an oven for baking, and bake at 60 degrees Celsius for 120 minutes to obtain a supermaterial with an acrylic resin film on the surface.

Embodiment 3

[0035] Put the room temperature curing two-component silicone resin glue with a viscosity of 12500cps in a container and stir evenly, impregnate the organic resin with metal microstructure etched on the surface into the resin glue, and keep it under vacuum for 1 minute to remove the air bubbles on the surface, then take it out Hang for 8 minutes to remove excess resin glue on the surface, send it to an oven for baking, and cure at room temperature for 24 hours to obtain a supermaterial with a silicone resin film on the surface.

[0036] The protective film of the metamaterial in this embodiment is a thermosetting resin film, and the loss of the protective film is small, so that the metamaterial antenna prepared by the metamaterial of this embodiment will not increase the loss of the antenna due to the loss of the protective film and affect its performance. performance, and the protective film is not easy to fall off in harsh outdoor environments, which can better protect the me...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap