Space overlaid and coupled high-power semiconductor laser stack array system

A space coupling, semiconductor technology, applied in the laser field, can solve problems such as complex process, achieve the effect of simple and compact structure, easy installation and debugging, and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

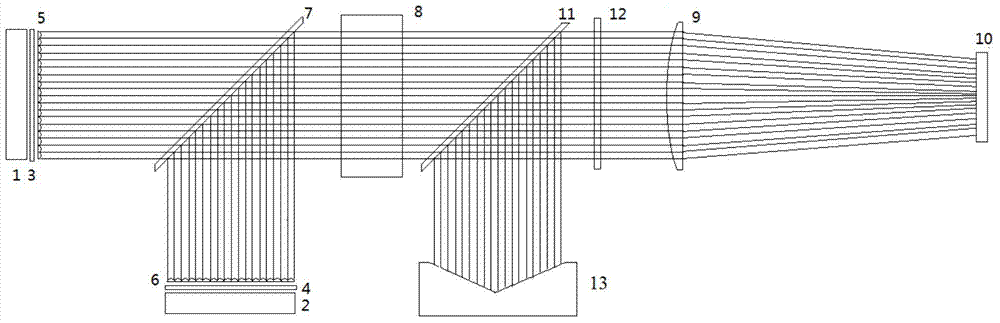

[0045] Following the technical solution of the present invention, the space superposition coupled high-power semiconductor laser array system of this embodiment includes a first semiconductor laser array 1, a second semiconductor laser array 2, a first fast-axis collimating lens group 3, a first Two fast-axis collimating lens groups 4, first slow-axis collimating lens array group 5, second slow-axis collimating lens array group 6, periodic space coupling mirror 7, slow-axis beam expander system 8, focusing mirror 9 , a polarizer 11 , a quarter wave plate 12 and a light blocker 13 . in:

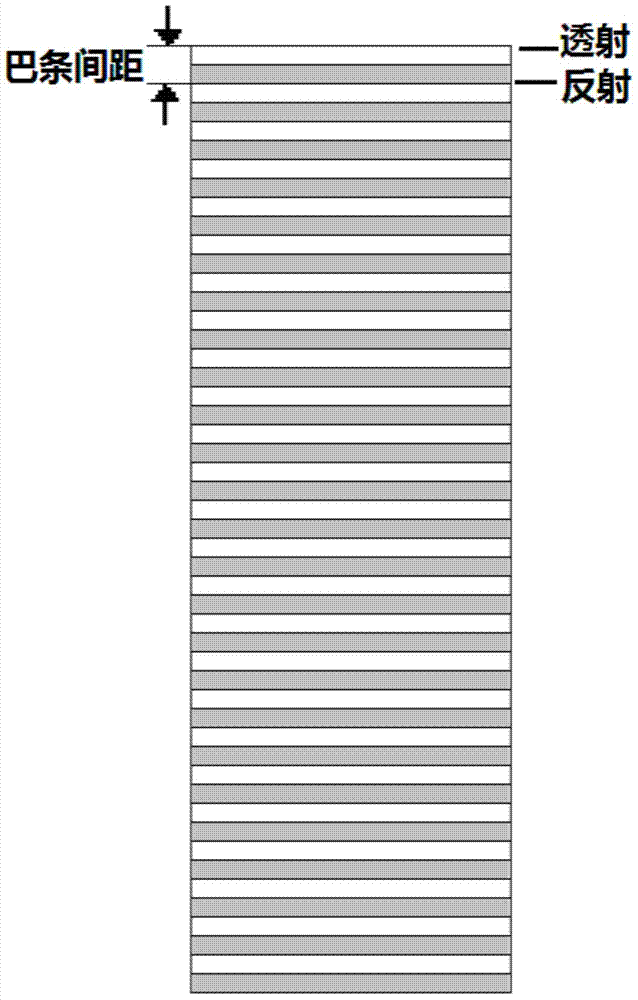

[0046] The first semiconductor laser stack 1 and the second conductor laser stack 2 are the same, and they all use a 3000-watt stack formed by stacking 25 semiconductor laser bars with a power of 976 nm and a power of 120 W along the fast axis direction. The total power of the first semiconductor laser array 1 and the second conductor laser array 2 is 6000 watts. like image 3 As shown in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com