Preparation method for magnetic lignin-based activated carbon

A technology based on lignin and activated carbon, applied in chemical instruments and methods, alkali metal oxides/hydroxides, inorganic chemistry, etc., can solve the problems of low corrosion and weak alkalinity of equipment, and achieve less pollutant discharge, Well-developed pores and high adsorption performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0023] In order to better understand the present invention, the present invention will be further described in detail below in conjunction with the examples, but the scope of protection claimed by the present invention is not limited to the scope represented by the examples.

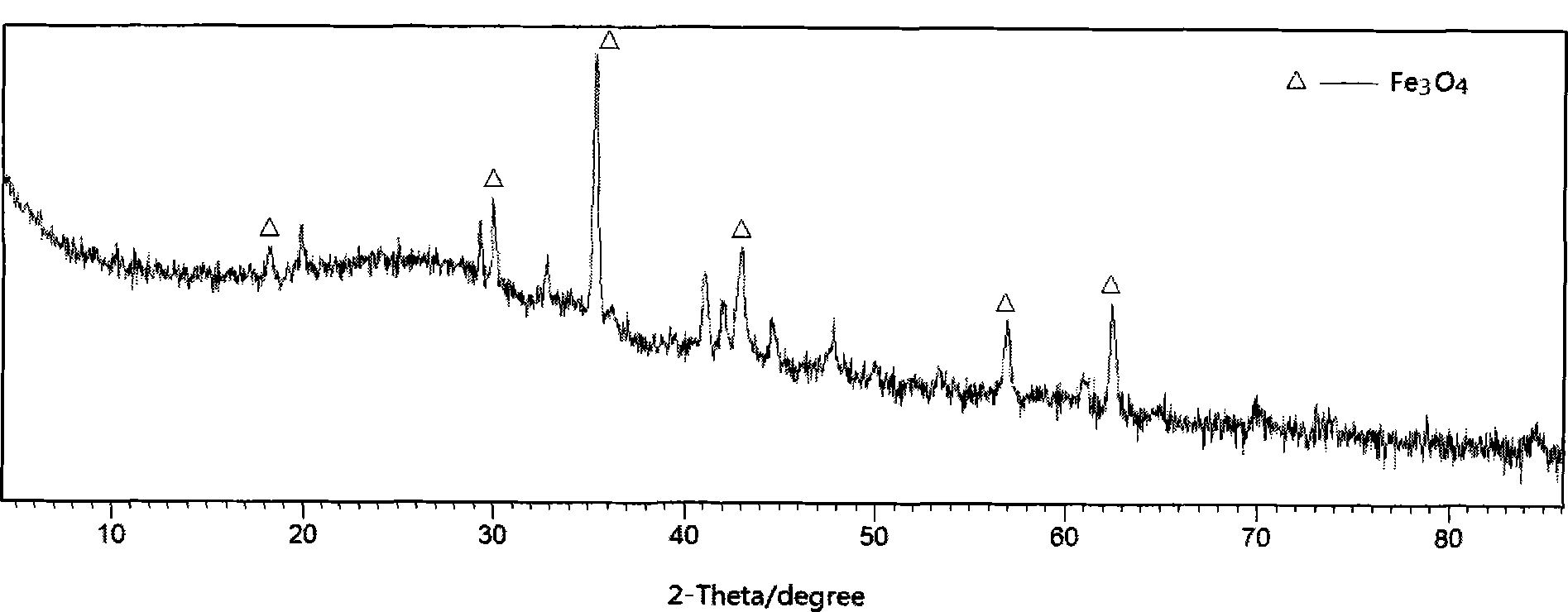

[0024] Embodiment 1~14 prepares the general technological process of magnetic activated carbon with lignin as follows:

[0025] Weigh lignin, activator and magnetic additive according to lignin:activator:magnetic additive=4:2-8:0.2-0.6 (mass ratio). The aqueous solution of lignin, magnetic additive and activator is adjusted into a paste, mixed evenly, and dried. Then, put it into a carbonization furnace and raise the temperature to 650-850°C for carbonization activation. The activation time is 0.5-3 hours, and then it is quenched and cooled. Wash with dilute acid and distilled water in sequence until the pH value is 6-8, dry and grind to obtain magnetic lignin-based activated carbon.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com