Catalyst for hydrogen production by water-phase reforming of biomass depolymerization product and preparation method thereof

A water-phase reforming technology for hydrogen production and depolymerization products, which can be used in metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., and can solve the problems of poor stability and high reactivity. problem, to achieve the effect of low synthesis temperature, simple preparation process and improved stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

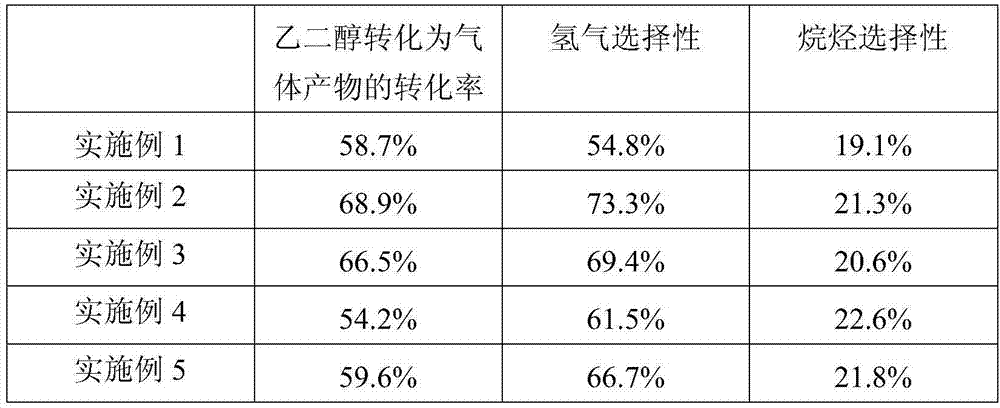

Examples

preparation example Construction

[0025] The preparation method of the biomass depolymerization product aqueous phase reforming hydrogen production catalyst of the present invention, the method comprises the following steps:

[0026] (1) Weigh Ni(NO 3 ) 2 ·6H 2 O2~5g, Fe(NO 3 ) 3 9H 2 O12~18g, Co(NO 3 ) 2 ·6H 2 O0.2~1.5g, citric acid 8~12g, under the condition of magnetic stirring, dissolve it in 30mL deionized water successively, obtain a kind of dark brown solution;

[0027] (2) Put the dark brown solution of (1) in an oil bath and heat up to 60°C-80°C, adjust the pH value of the reaction solution to 8-10 with ammonia water by adding drop by drop, and continue stirring at constant temperature for 5-80°C. 8h obtains viscous solution;

[0028] (3) Put the viscous solution obtained in (2) in an oven, and bake at 110°C for 12h to 24h to obtain a yellow-brown solid;

[0029] (4) Put the yellow-brown solid obtained in (3) in a muffle furnace, and roast it at 300-500°C for 3-5 hours to obtain a coral-like...

Embodiment

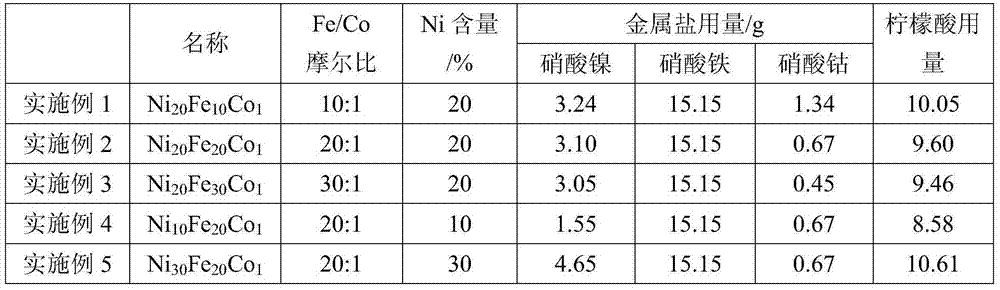

[0031] Weigh a certain amount of Ni(NO 3 ) 2 ·6H 2 O, Fe(NO 3 ) 3 9H 2 O, Co(NO 3 ) 2 ·6H 2 O and citric acid were dissolved in 30 mL of deionized water, the molar ratio of citric acid: (Ni+Fe+Co) was 1:1, and the dosage of each component was shown in Table 1. Stir the mixture in an oil bath at 60°C, add ammonia water drop by drop to adjust the pH value to 8, continue stirring at a constant temperature for 6 hours, then dry at 110°C for 12 hours, roast in a muffle furnace at 400°C for 3 hours, grind, press flakes, pulverized, and passed through 20-40 mesh sieves to obtain different Ni / Fe / Co catalysts.

[0032] Table 1 Ni / Fe / Co / citric acid dosage of different catalysts

[0033]

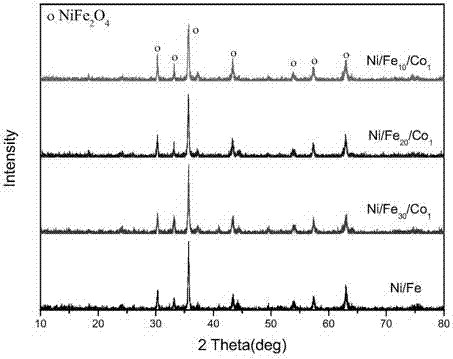

[0034] Depend on figure 1 The XRD spectrogram can be obtained, in the Ni / Fe / Co multi-metal composite catalyst prepared under this condition, Ni and Fe are NiFe 2 o 4 The alloy form existed in the catalyst, and no characteristic diffraction peaks of Co were found, indicating that Co was h...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com